Precisely Locating Fault Points of Optical Cable Lines Using Manual Faults of Optical Cables

A line fault and precise positioning technology, applied in electromagnetic wave transmission systems, electrical components, transmission systems, etc., can solve the problem of low positioning accuracy, and achieve the effect of improving positioning accuracy, efficient promotion, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

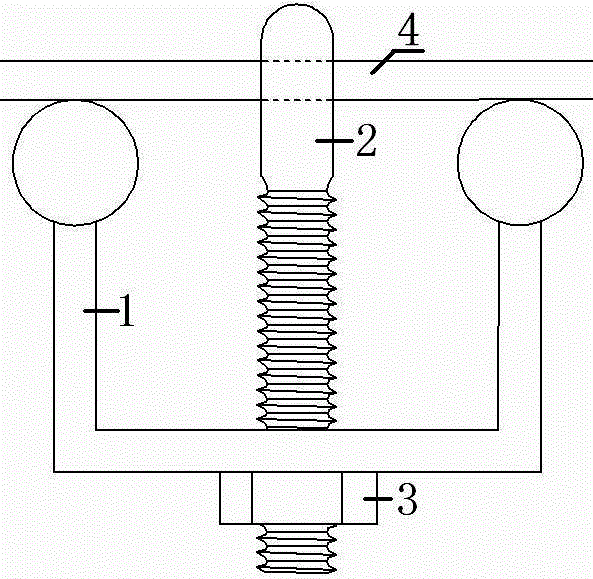

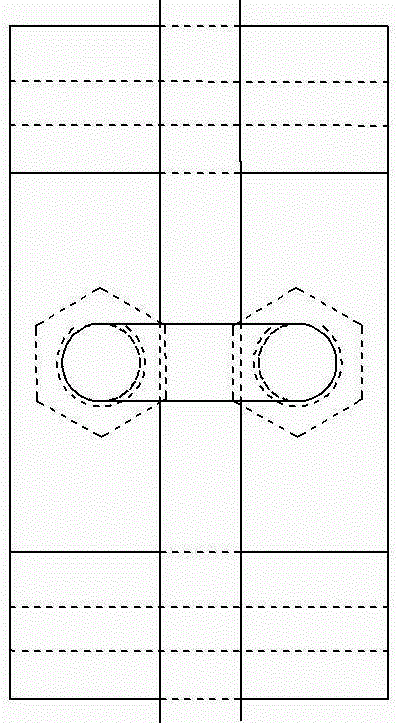

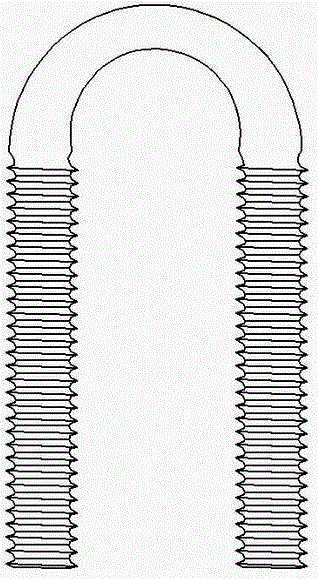

[0039] In this example, the OTDR uses Yokogawa AQ7275, the optical cable adopts GYTS-24B1 optical cable, the optical fiber adopts ITU-T G.652 standard single-mode optical fiber, and the diameter of the optical cable is 11mm. The schematic diagram of the optical cable structure is as follows figure 1 shown. The optical cable cards are all metal, and the structure is as follows: image 3 The shown includes bracket 1, U-shaped rod 2, and nut 3, in which a cylinder is fixed at both ends of bracket 1, and the radius of the cylindrical surface is 16 mm, which is greater than the critical curvature radius of the optical fiber. There are two round holes on the center line of the base of bracket 1, and the U-shaped rod 2 can be pierced through the round hole, the U-shaped rod 2 has threads, and the rotating nut 3 can make the U-shaped rod 2 move up and down. The side height of the bracket 1 is 46mm, and the bottom surface width is 80mm. After reaching the bottom end, the optical cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com