An anti-corrosion and explosion-proof self-control temperature electric heating cable

An electric heating cable and self-temperature control technology, which is applied in the direction of the shape of the heating element, etc., can solve problems such as interference, working environment influence, and affecting the normal operation of the electric heating cable, and achieve high heating efficiency, enhanced heat conduction effect, and enhanced anti-electromagnetic interference performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

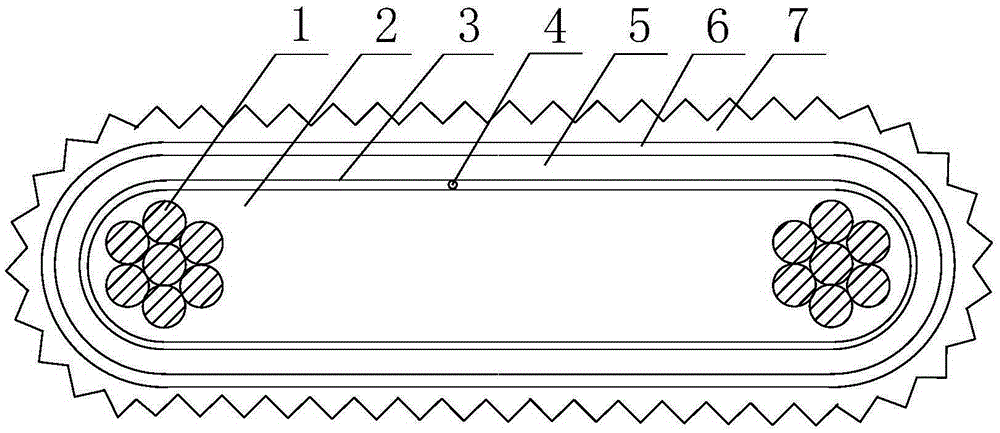

[0016] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of an anti-corrosion and explosion-proof self-control temperature electric heating cable proposed by the present invention.

[0017] refer to figure 1 , an anti-corrosion and explosion-proof self-control temperature electric heating cable proposed by the present invention, which includes a PTC material core 2 inside.

[0018] The PTC material core 2 is made of carbon-added conductive plastic, and two wires 1 are arranged inside the PTC material core 2, and each wire is formed by twisting 7 tinned copper wires. The PTC material core 2 is made of carbon-added conductive plastic.

[0019] The PTC material core 2 is coated with a single-sided aluminum-plastic composite layer 3, the plastic layer of the single-sided aluminum-plastic composite layer 3 faces inward, and the aluminum layer faces outward, which acts as a protective layer for the core body, which can prevent moisture and external chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com