Patents

Literature

36results about How to "Improve electrothermal performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

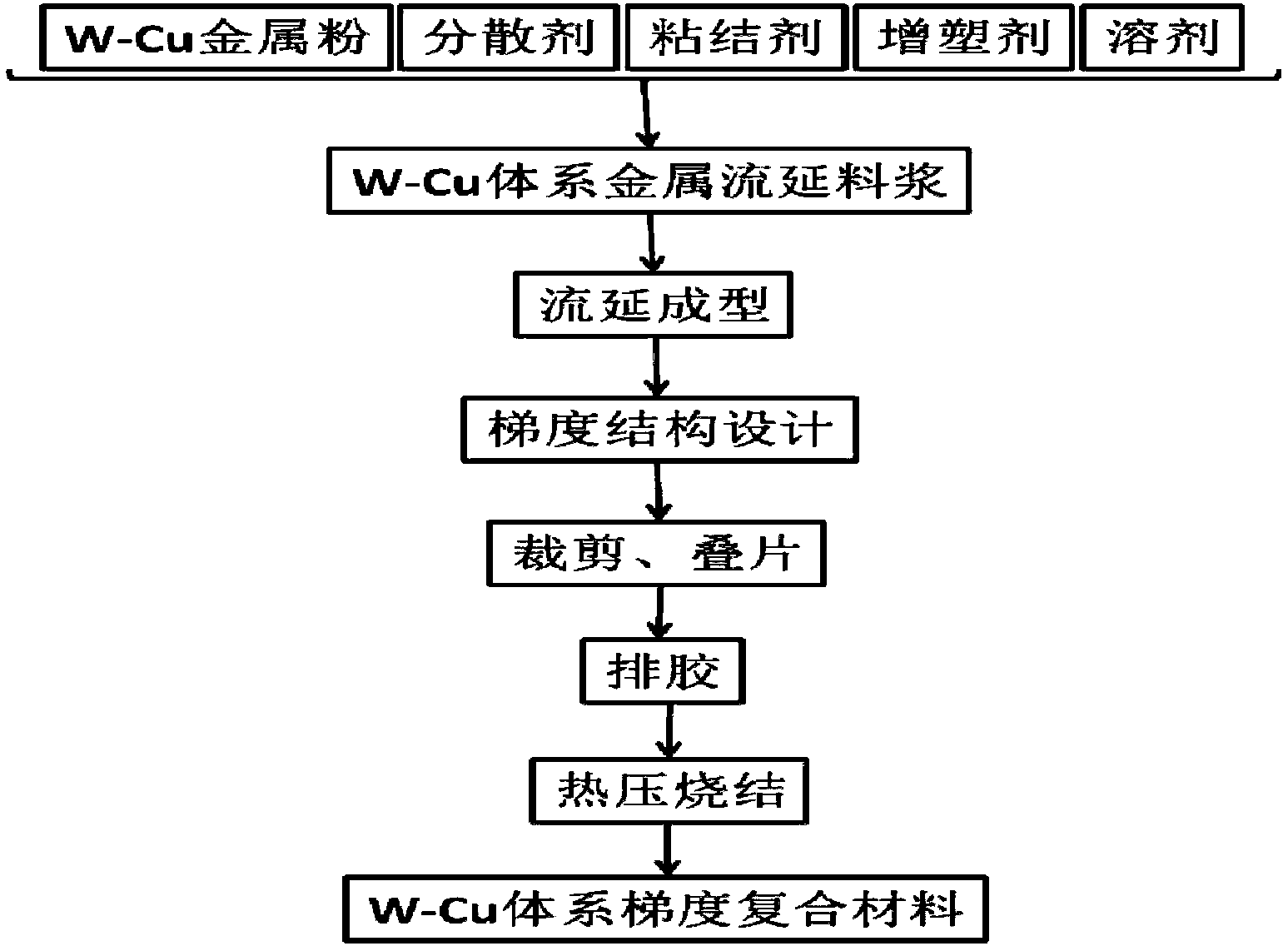

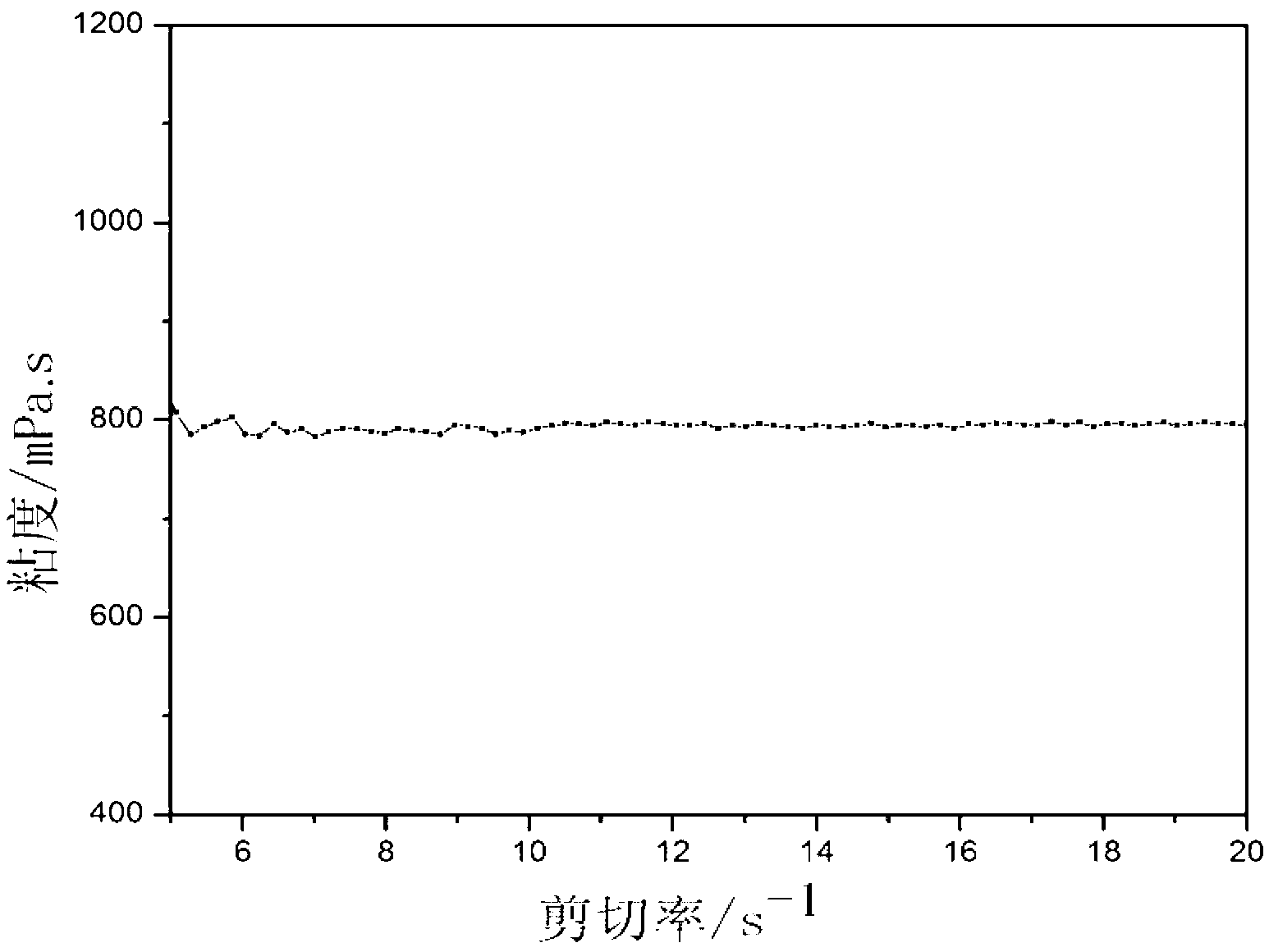

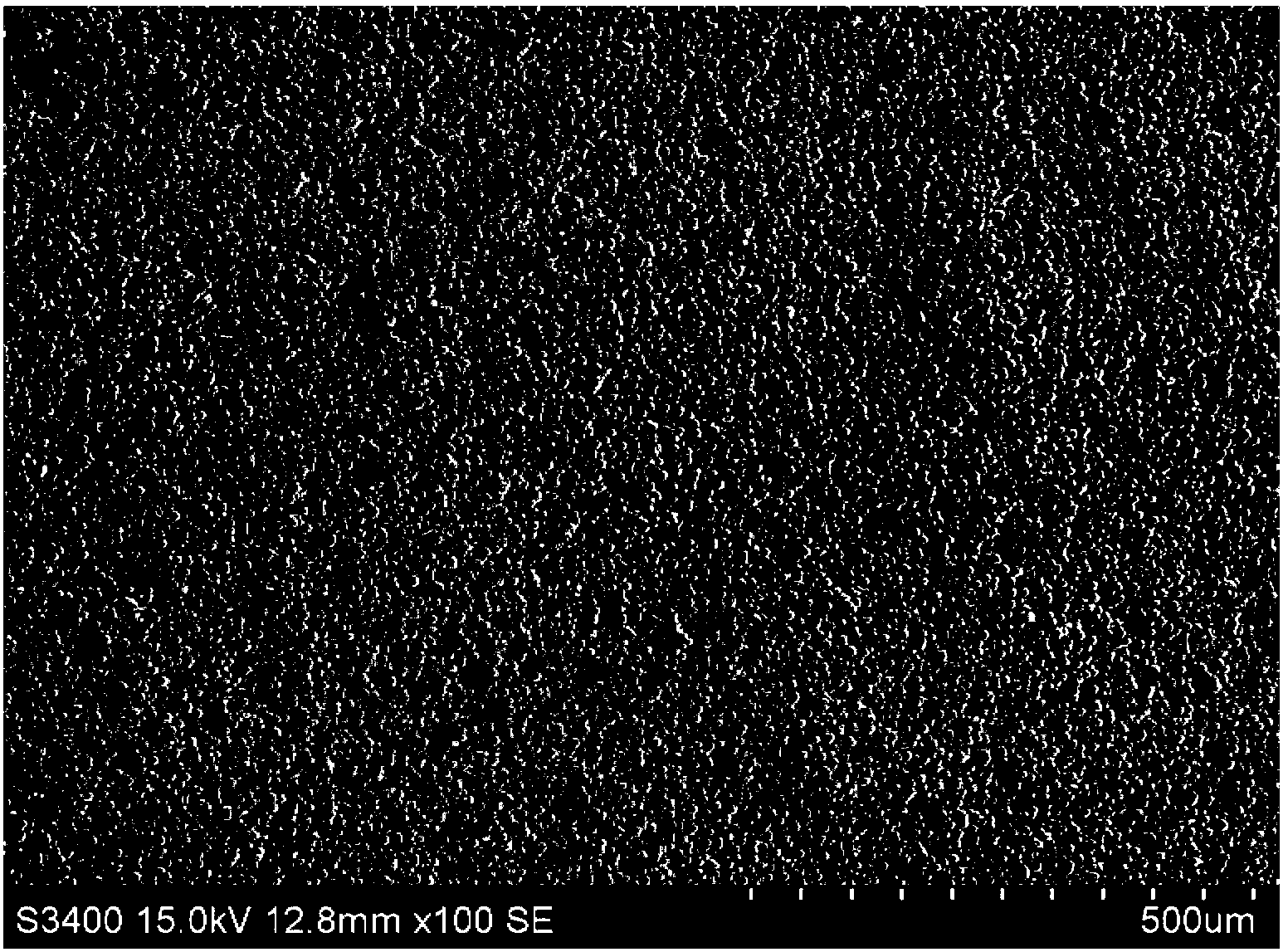

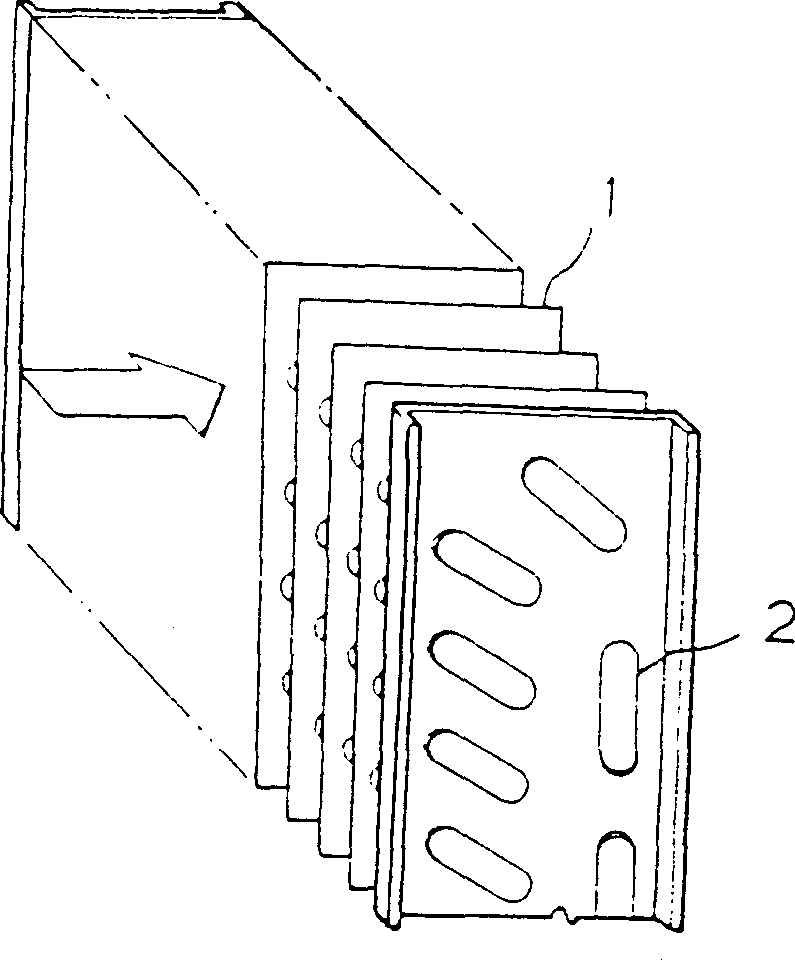

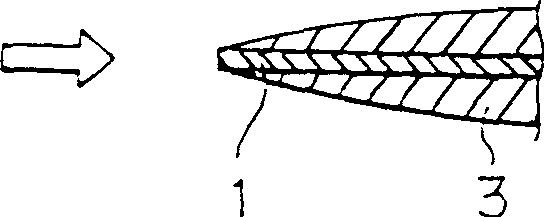

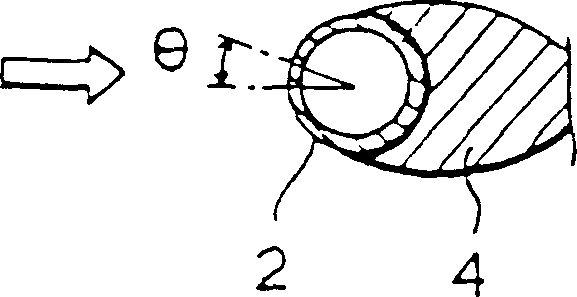

Method for manufacturing gradient composite of W-Cu system by aid of tape casting process

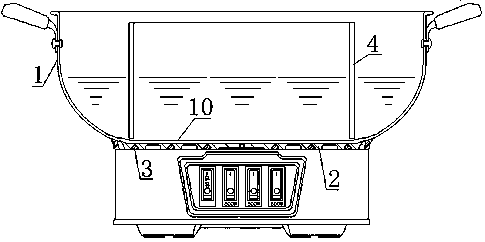

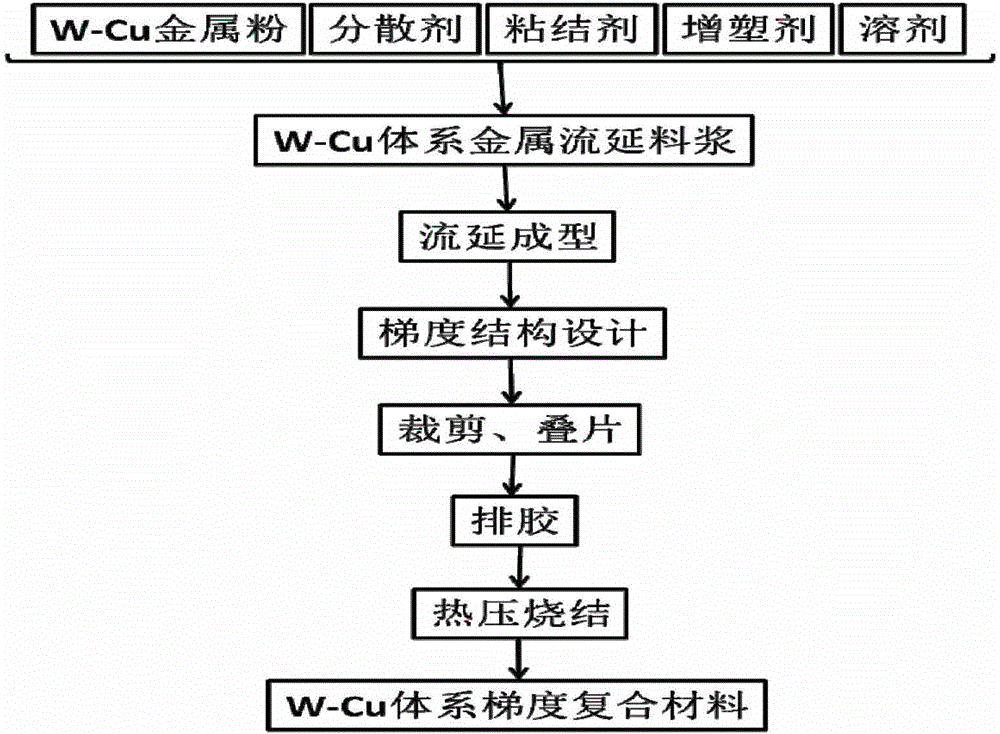

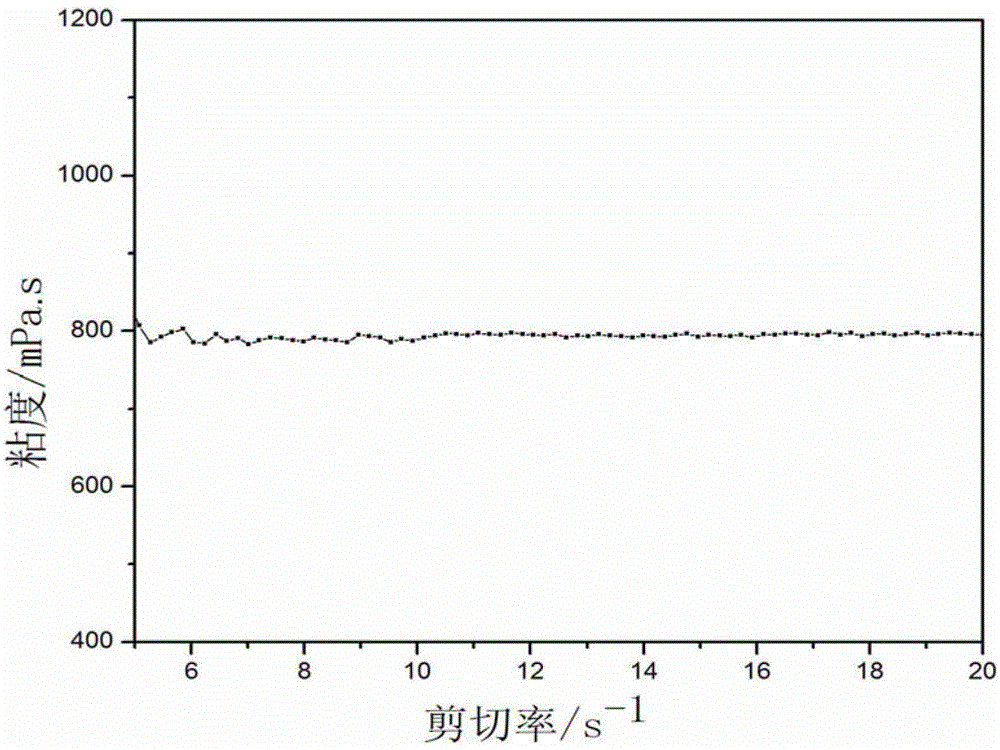

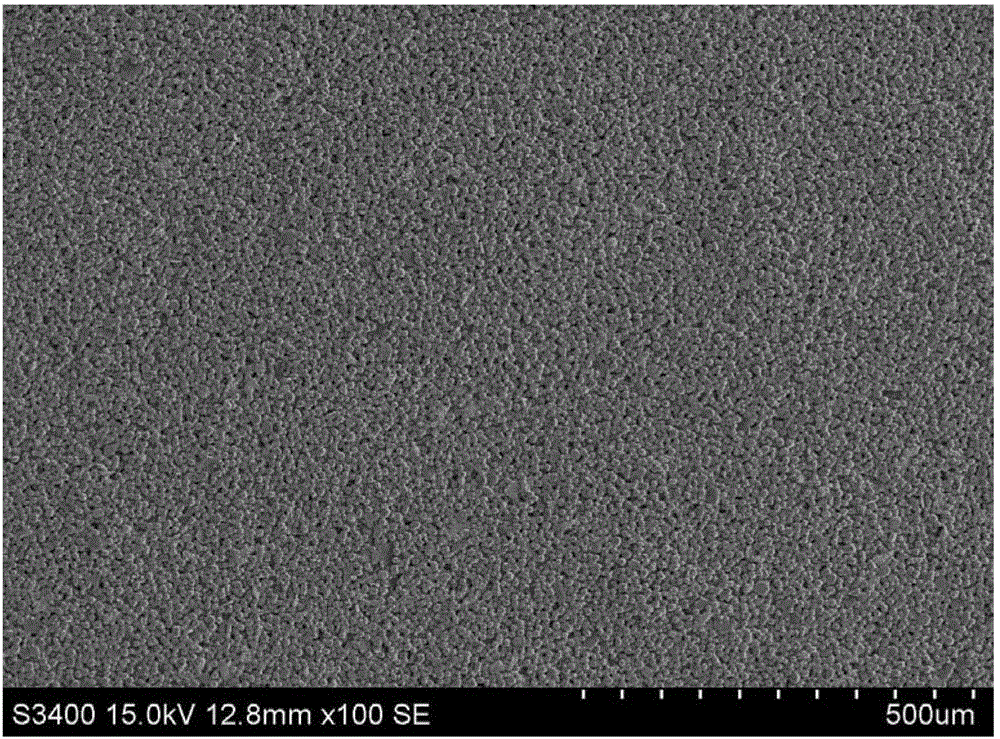

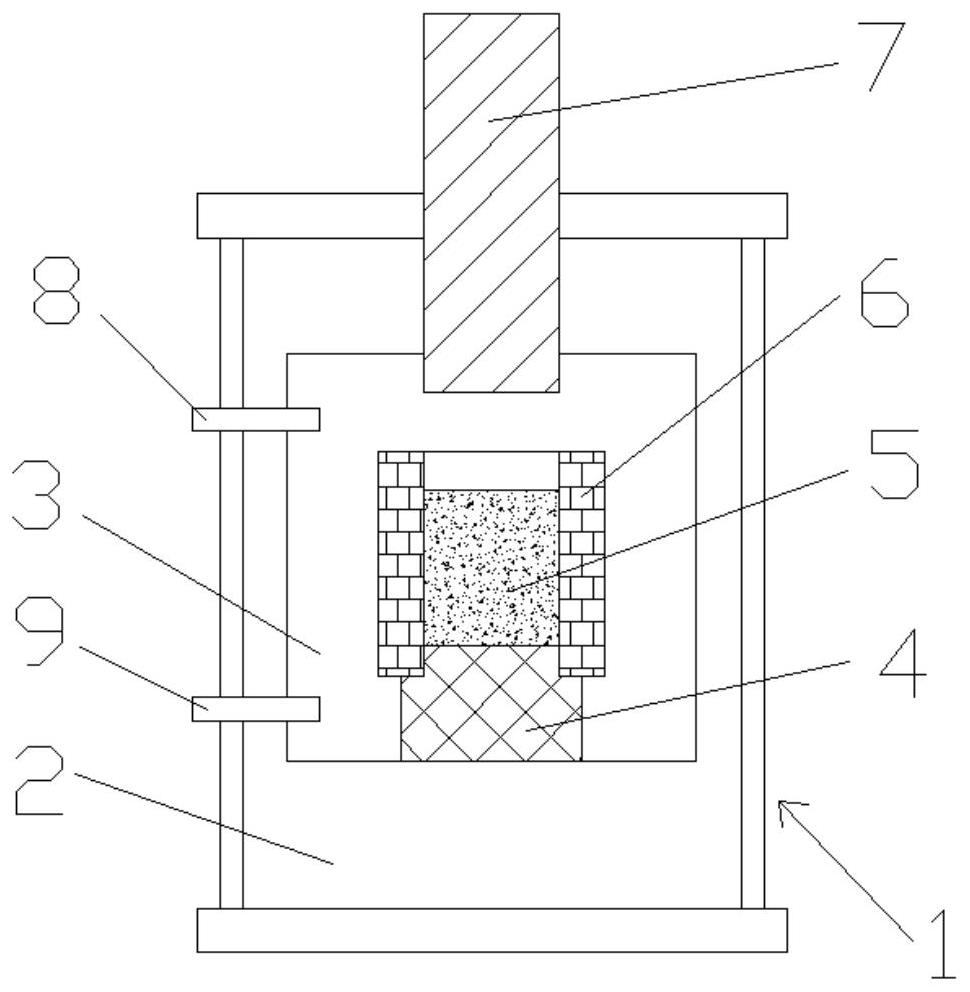

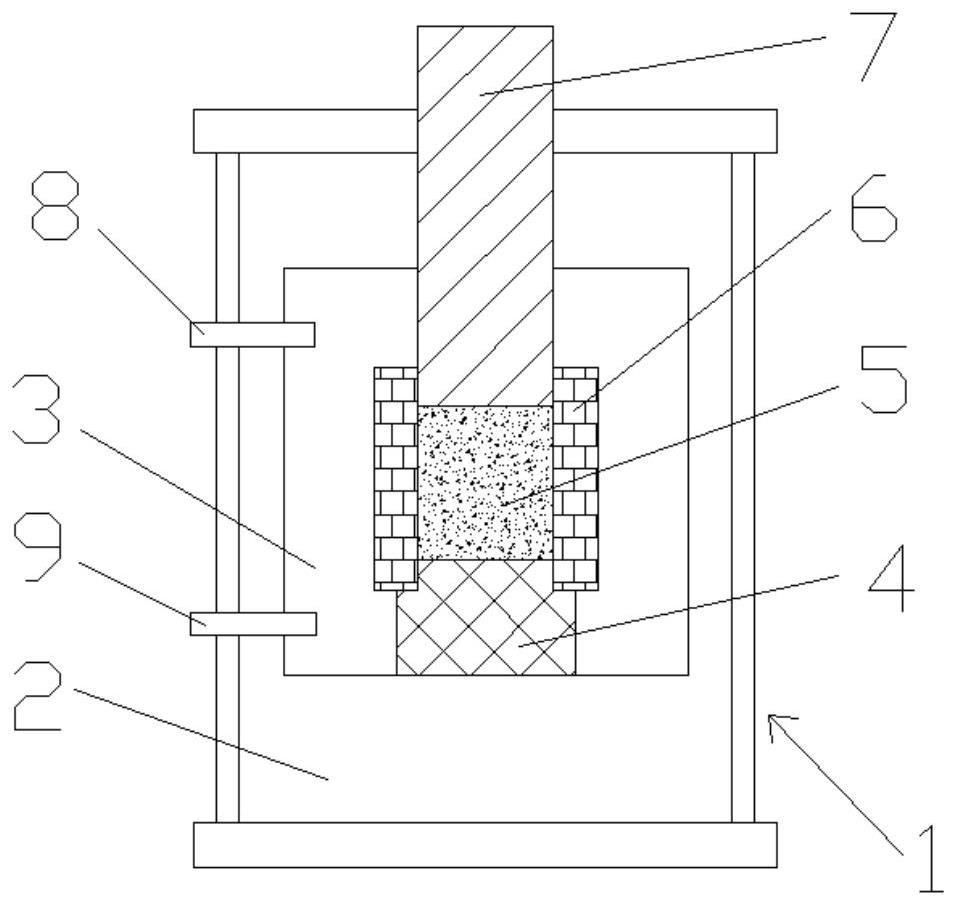

The invention relates to a method for manufacturing a gradient composite of a W-Cu system by the aid of a tape casting process. The method includes steps of (1), manufacturing metal powder non-water-based tape casting slurry and performing tape casting: defoaming and filtering metal powder non-water-based slurry which is mixed by means of ball milling, then performing tape casting on the metal powder non-water-based slurry a tape casting machine, and drying the metal powder non-water-based slurry in air to obtain a single-component metal tape casting membrane; (2), designing, cutting and laminating a gradient structure: cutting tape casting diaphragms with different W-Cu components according to a design of a thickness-direction distribution function C=C<0>+AXx of copper contents, and laminating the cut tape casting diaphragms to form a green body with the gradient structure; (3), removing adhesive of the green body and performing hot pressed sintering: removing the adhesive of the green body in nitrogen and hydrogen mixed atmosphere, and then performing hot pressed sintering on the green body in a vacuum hot press furnace. The method has the advantages that a technology is simple, the cost is low, the thickness of a single-component layer of the composite manufactured by the method can reach a micron dimension, variation of a component is gentle, a transitional layer is smooth and continuous, and the gradient composite is excellent in electro-thermal performance and can be applied to the thermoelectric fields of electric contacts, electronic packaging and the like.

Owner:WUHAN UNIV OF TECH

Steel slag carbon fiber conductive concrete and preparation method thereof

The invention discloses steel slag carbon fiber conductive concrete, which is prepared from the following components: 98-102 parts of cement, 100-110 parts of sand, 150-165 parts of crushed stone, 1.6-2.0 parts of carbon fibers, 50-55 parts of water, 15-16 parts of fly ash, 0.8-1.5 parts of a water reducing agent, 0.03- 0.1 part of a defoaming agent, 0.4-0.73 part of a dispersing agent and 16-26 parts of steel slag powder. The steel slag carbon fiber conductive concrete provided by the invention adopts steel slag, the carbon fibers, the dispersing agent and the like which have a synergistic effect, and has good electrical conductivity; the electrical resistivity of the conductive concrete can be reduced to 0.65 omega.m and is close to the resistivity of the conventional carbon fiber concrete; but due to the addition of the steel slag lower in cost, and the consumption of the carbon fibers higher in cost is reduced, so that the manufacturing cost is further lowered on the whole; the dispersity of the carbon fibers in the steel slag carbon fiber conductive concrete is good, so that the compressive strength and electric heating performance of the concrete are both improved.

Owner:ZHENGZHOU UNIV

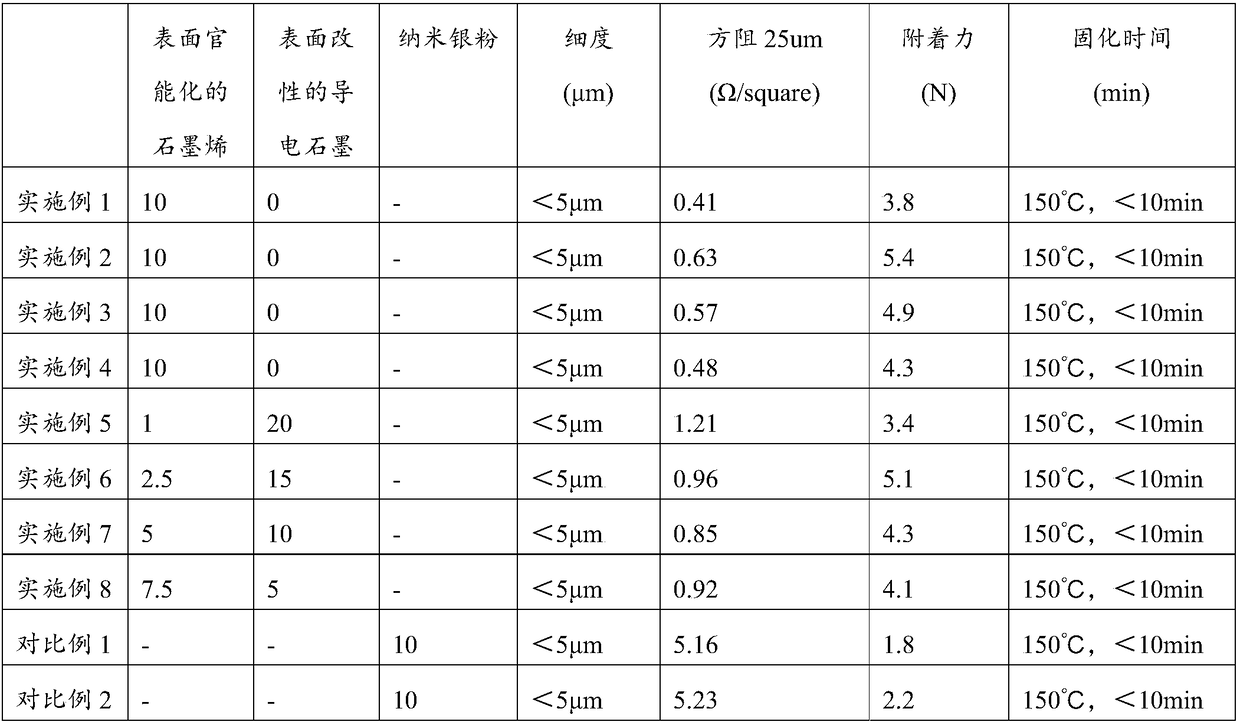

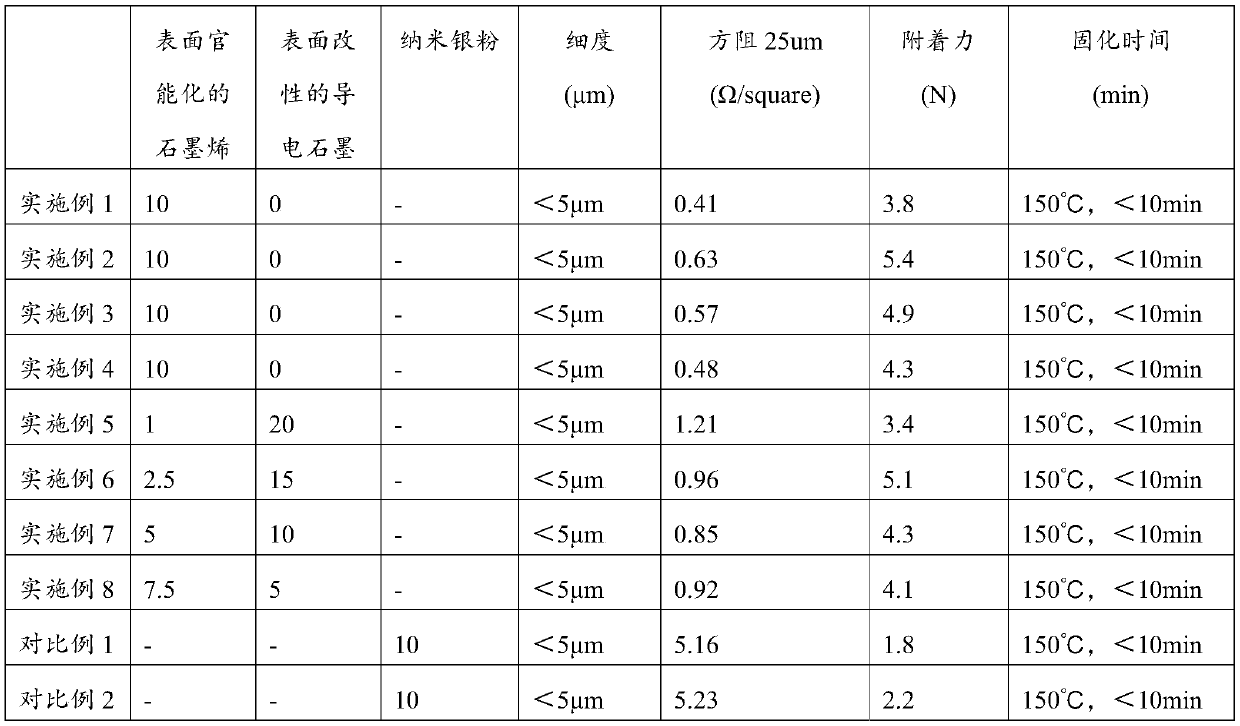

Graphene conductive paste and preparation method thereof

ActiveCN108257710AExcellent bonding strengthGood flexibility and resistance to photothermal degradationNon-conductive material with dispersed conductive materialCable/conductor manufactureSilane couplingSiloxane

The application relates to the field of conductive pastes, in particular to a graphene conductive paste. The graphene conductive paste comprises the following components, by weight: 1 to 10 parts of epoxy-functionalized graphene, 4 to 15 parts of epoxy resin, 2 to 6 parts of epoxy-modified siloxane, 2 to 6 parts of epoxy reactive diluents, and 0.1 to 0.8 parts of latent curing agents. Furthermore,the graphene conductive paste also includes 5 to 20 pars, by weight, of conductive black modified with a silane coupling agent. In addition, the application also provides a method for preparing the graphene conductive paste. The method includes: carrying out epoxy functionalization of graphene powder; carrying out epoxy modification of siloxane; carrying out mixing and stirring of all components;and carrying out conductive black modification. According to the graphene conductive paste provided by the application, the high dispersibility of graphene and good adhesion of the conductive paste are realized; and with the conductive black, the amount of graphene is reduced and the cost is lowered.

Owner:SHENZHEN HOVERBIRD ELECTRONICS TECH CO LTD

Self-healing asphalt concrete based on microwave heating and containing metal fibers and preparation method of self-healing asphalt concrete

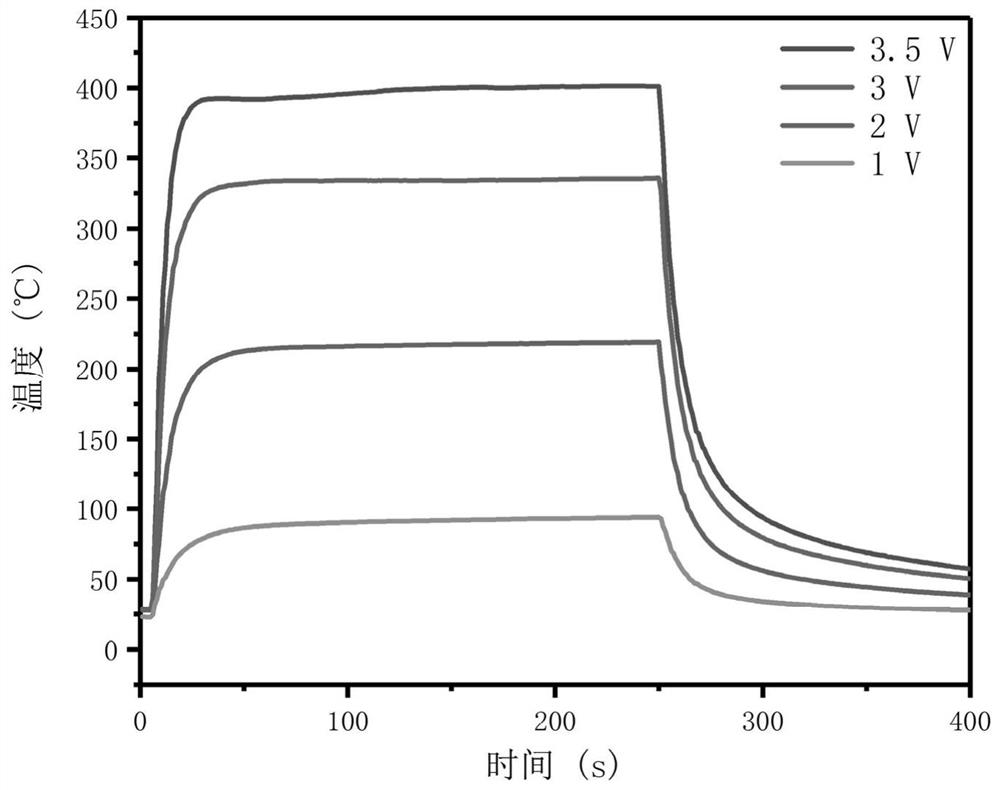

InactiveCN105152581AImprove electrothermal performanceGood for melting ice and snowSelf-healingMicrowave

The invention discloses self-healing asphalt concrete based on microwave heating and containing metal fibers. The self-healing asphalt concrete is prepared from raw materials in parts by weight as follows: 60-70 parts of coarse aggregate, 20-30 parts of fine aggregate, 4-6 parts of pulverized steel slag powder filler, 4-6 parts of asphalt and a conductive material accounting for 2%-5% of the volume of the asphalt. During preparation, steel wool fibers are added to the asphalt at the temperature of 160-170 DEG C and stirred uniformly, the mixture is stirred uniformly with the coarse aggregate and the fine aggregate which are heated to the temperature of 170-180 DEG C, then the pulverized steel slag powder filler is added and stirred uniformly, and a mixture is obtained; a Marshall compaction apparatus is used for compacting both sides of the mixture for 75 times respectively or a rotary compaction apparatus is used for compacting the mixture for 100 times, and the concrete is obtained. Compared with the prior art, the self-healing asphalt concrete based on microwave heating and containing the metal fibers has the advantages as follows: the formula is simple, the construction is convenient, the electrothermic performance and the pavement performance of an asphalt pavement are improved, especially the self-healing capacity of cracks is remarkably improved, ice and snow melting of the asphalt pavement in winter is facilitated, and the resource utilization rate of steel slag as solid waste is further increased.

Owner:CHANGAN UNIV

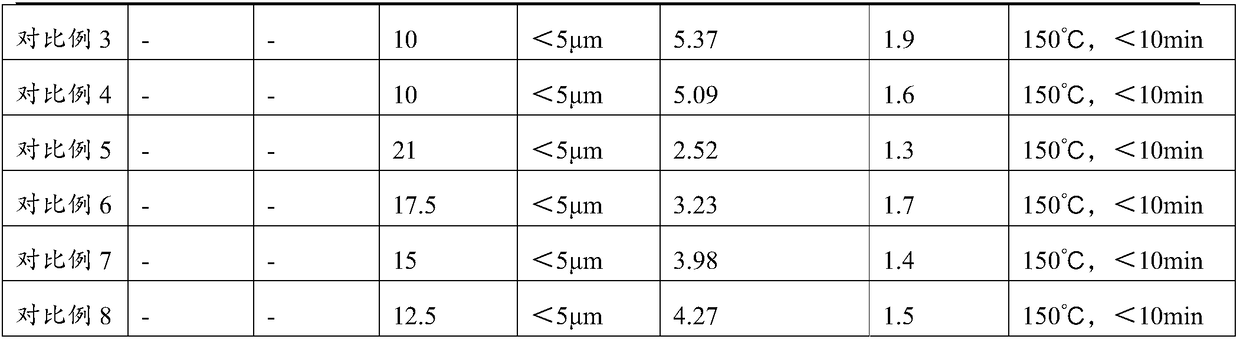

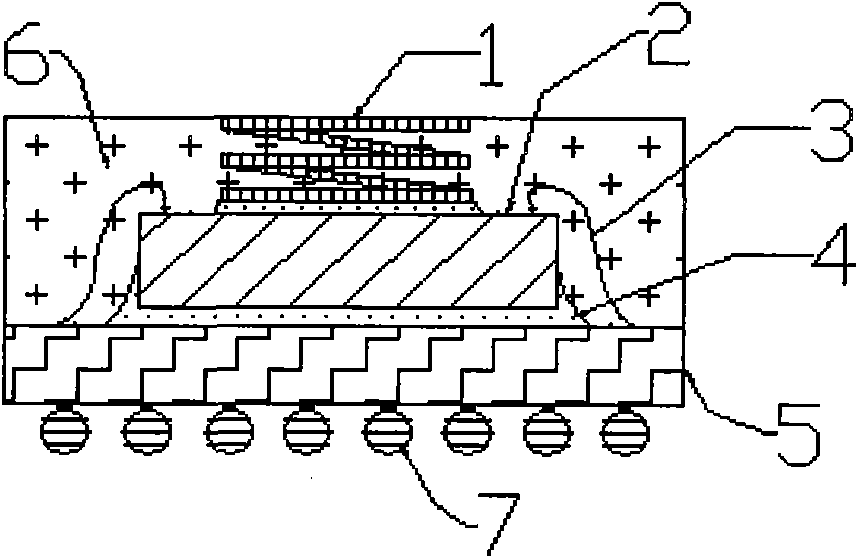

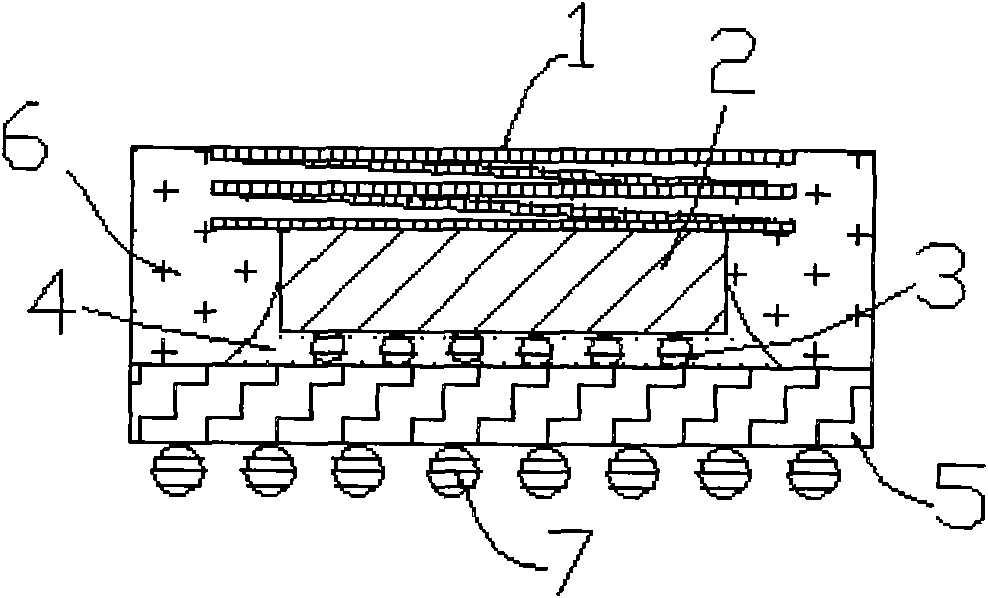

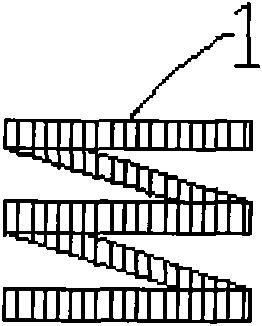

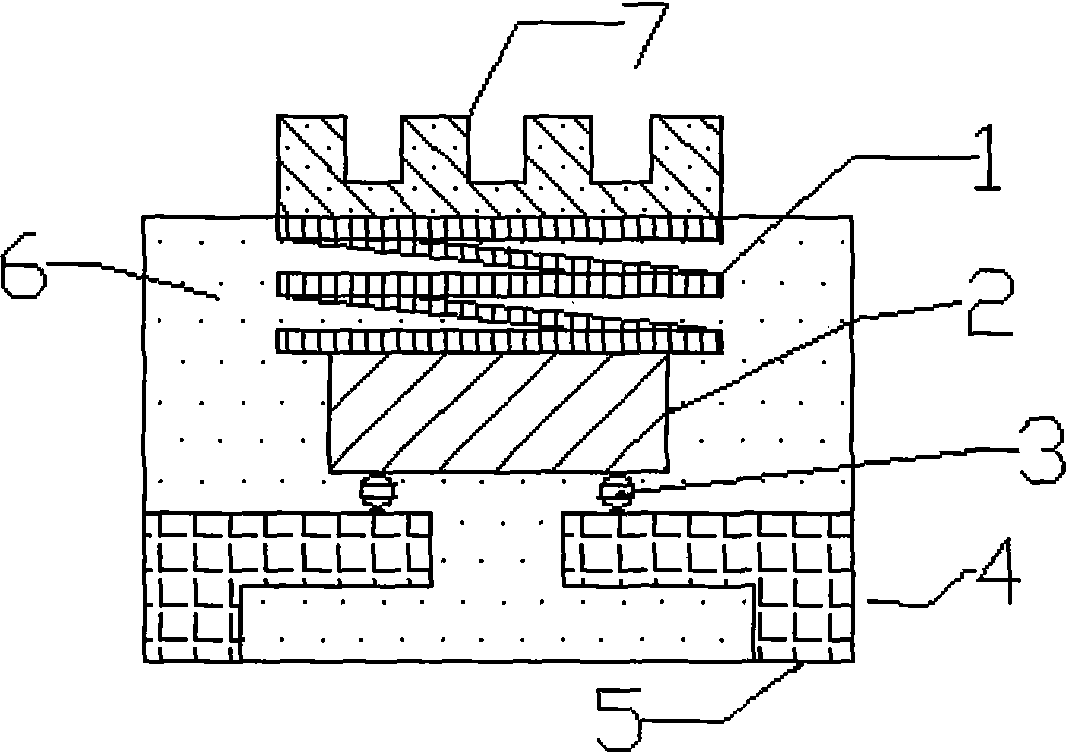

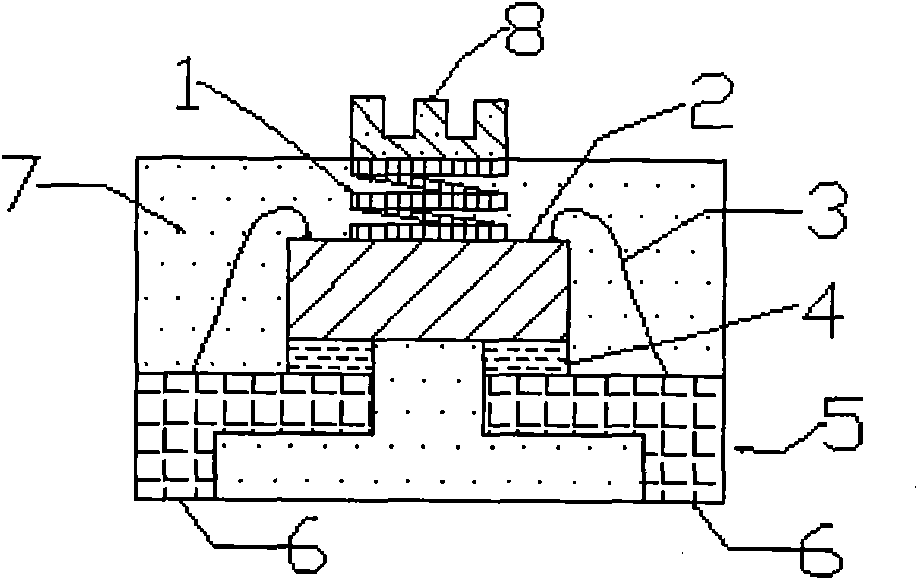

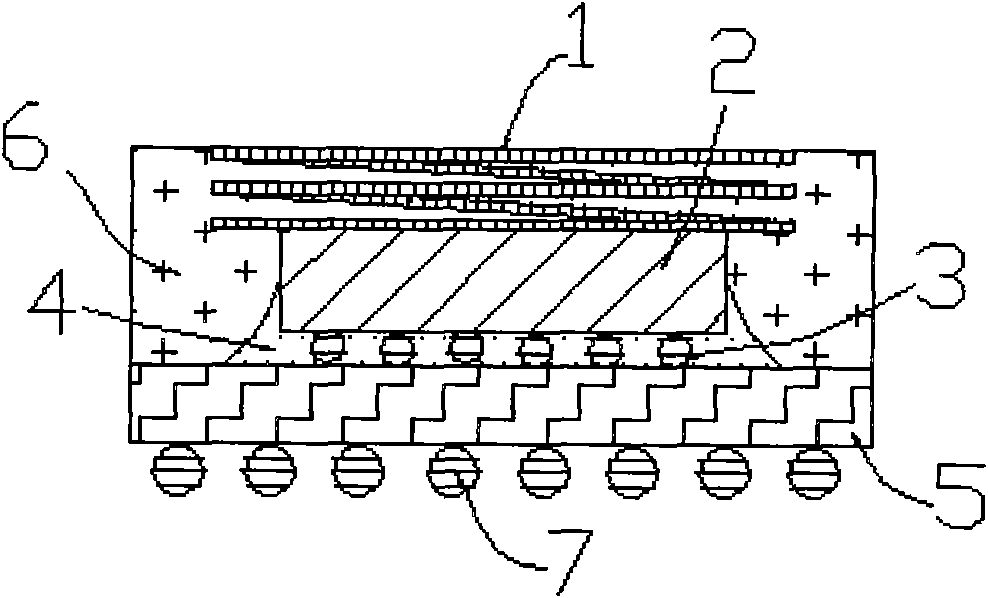

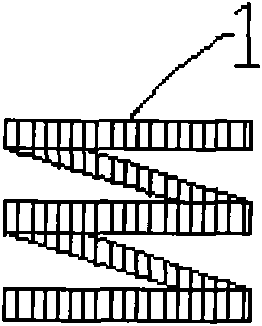

High-heat-dispersion spherical array encapsulation method

ActiveCN101834150AIncrease cooling areaSolve package heat dissipation problemsSemiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringMetal

The invention relates to a high-heat-dispersion reverse solder spherical array encapsulation method which comprises the following steps of: implanting a chip into a substrate by using a binding material; pasting a spring radiator on the chip; electrically connecting the chip and the substrate by a metal lead; plastically encapsulating the spring radiator, the chip, the metal lead, the binding material and the substrate with a plastic encapsulating material to form a plastic encapsulated body; and fixing the periphery of the spring radiator by the plastic encapsulating material, wherein one end of the spring radiator is connected with the chip, and the other end is exposed out of the surface of the encapsulated body so that the heat of the chip is dispersed out of the encapsulated body. The invention solves the problems of heat dispersion in encapsulation without an exposed metal carrier plates and greatly improves the electrothermal performance and the reliability of the product.

Owner:NANTONG FUJITSU MICROELECTRONICS

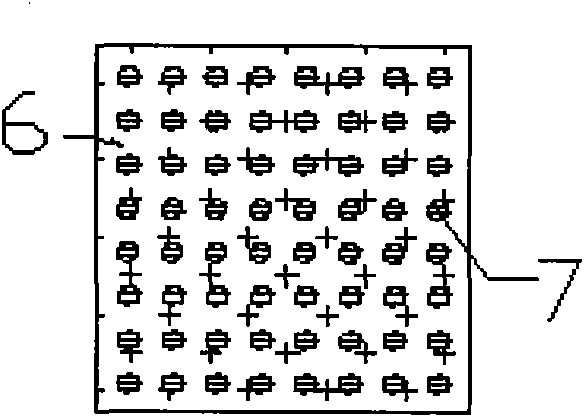

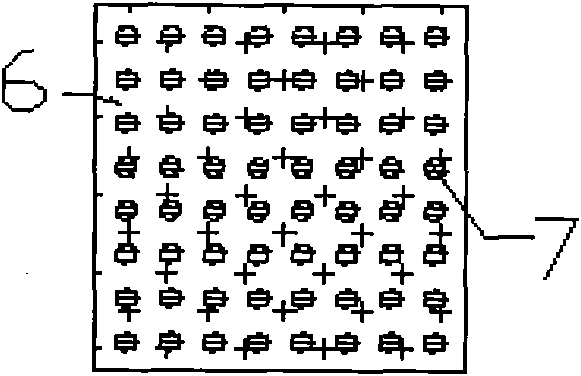

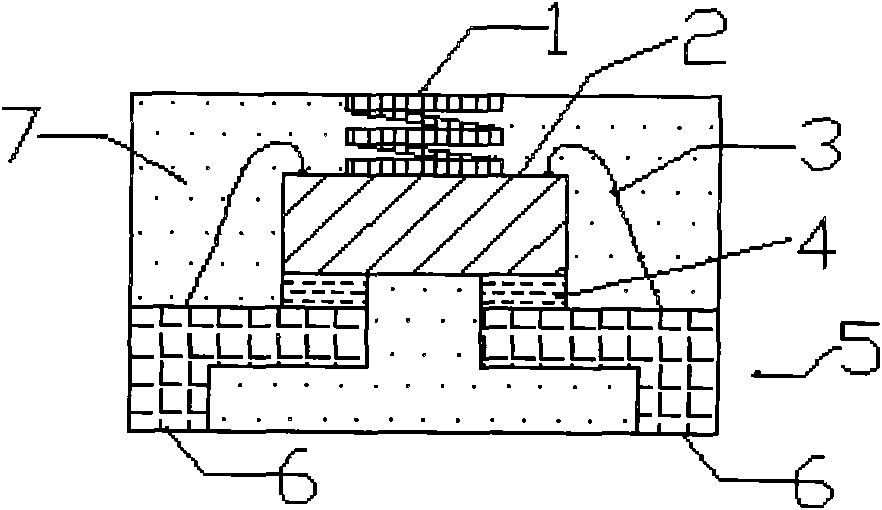

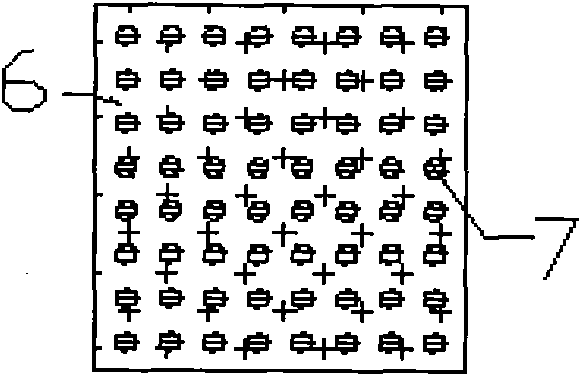

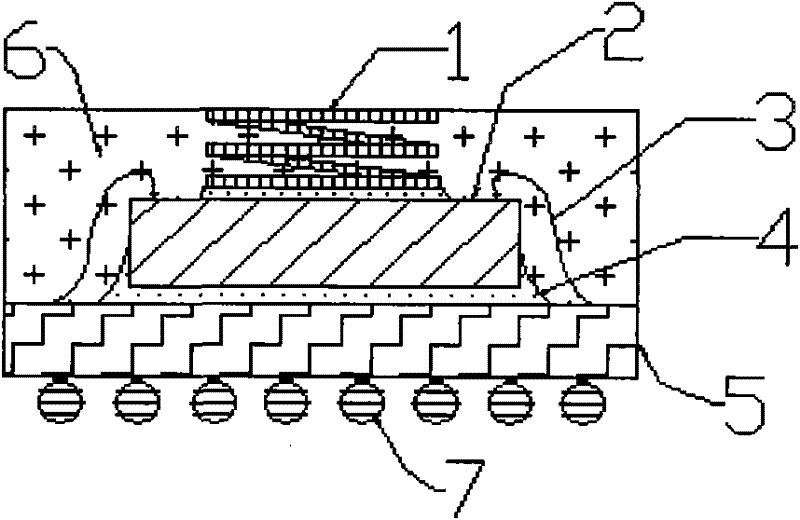

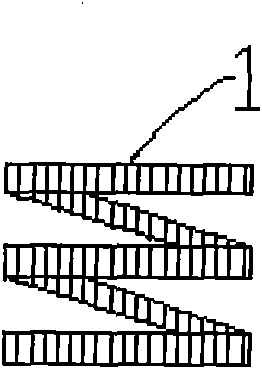

Flip-chip high-heat-radiation spheroidal array encapsulation structure

ActiveCN101840896AIncrease cooling areaSolve the cooling problemSemiconductor/solid-state device detailsSolid-state devicesSolder ballInterconnection

The invention relates to a flip-chip high-heat-radiation spheroidal array encapsulation structure, which comprises a chip, an electric interconnection material, a lower filling material, a base plate, a plastic sealing material and a welding ball. A spring heat radiator is also arranged in the encapsulation structure. The electric interconnection material is planted on the front side of the chip, and is inversely arranged on the base plate, and the electric interconnection between the chip and the base plate is realized through the electric interconnection material, the lower filing material fills a gap between the chip and the base plate, the plastic sealing material plastically seals the spring heat radiator, the chip, the electric interconnection material, the lower filling material and the base plate for forming a plastic sealing body, the circumambience of the spring heat radiator is fixed by the plastic sealing material, one end of the spring heat radiator is connected with the chip, and the other end of the spring heat radiator is exposed on the surface of the plastic sealing body for radiating the heat of the chip out of the plastic sealing body. The problem of heat radiation of the encapsulation of carrying bases or inversely arranged chips without exposed metals is solved, and the electric heating performance and the reliability of the products are greatly improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

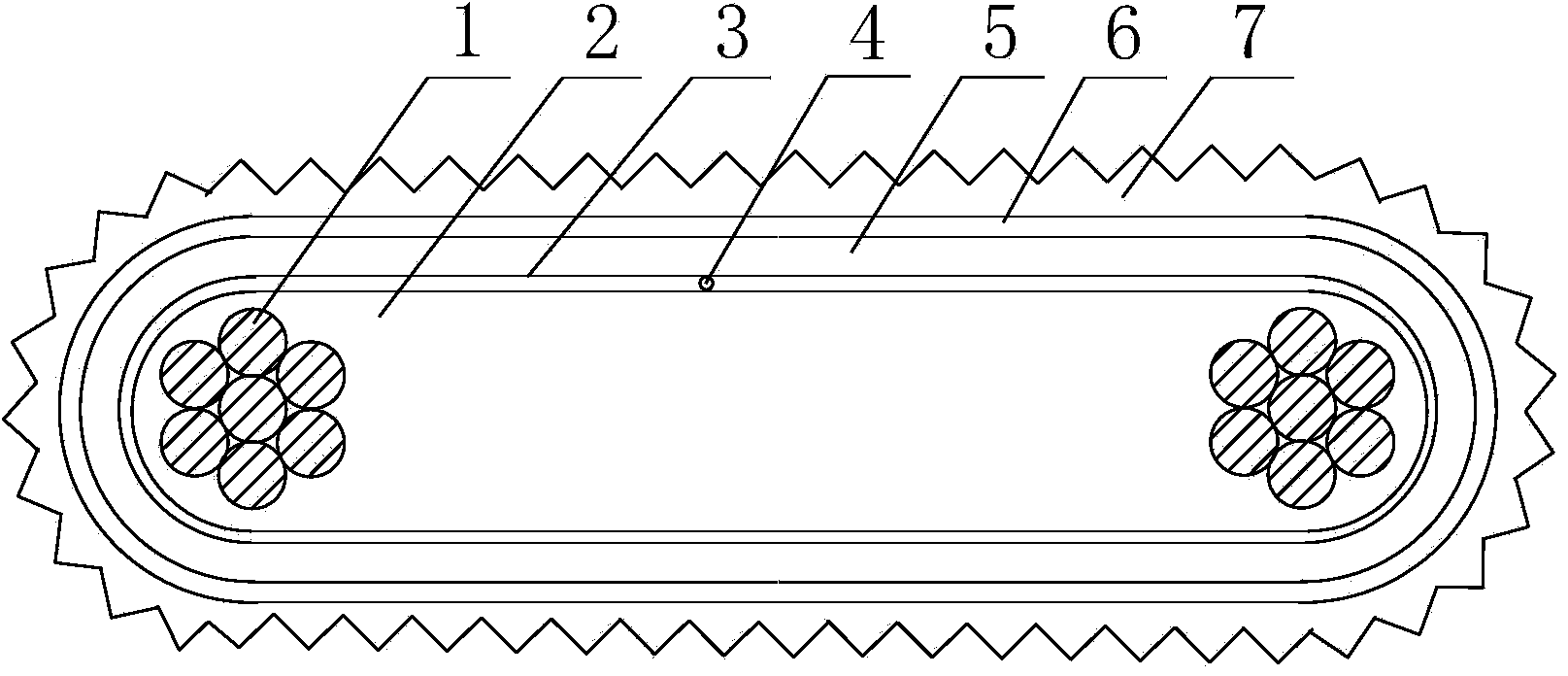

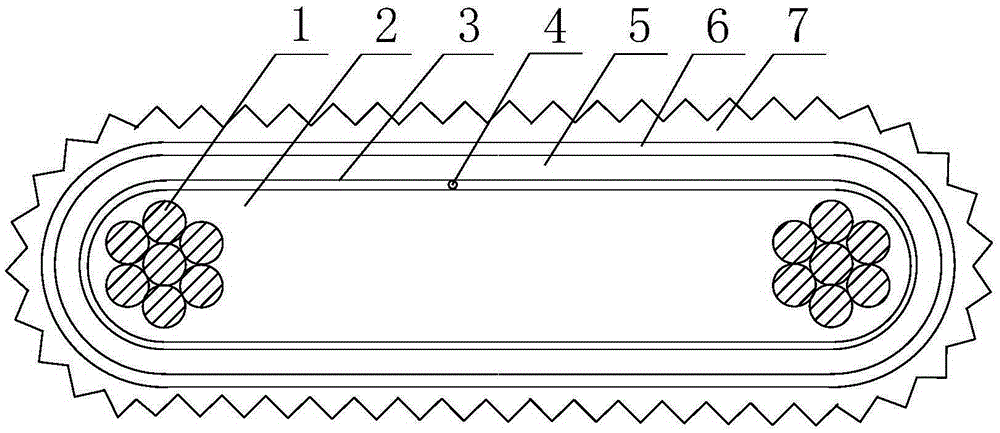

Anti-corrosion and anti-explosion self-temperature-control electric tracing band

The invention discloses an anti-corrosion and anti-explosion self-temperature-control electric tracing band. The anti-corrosion and anti-explosion self-temperature-control electric tracing band comprises a PTC material core which is internally provided with two wires, the PTC material core is wrapped by a single-face metal and plastic composite belt which is internally provided with a drainage wire, the plastic layer of the single-face metal and plastic composite belt faces inwards, and the metal layer of the single-face metal and plastic composite belt faces outwards. The metal and plastic composite belt is wrapped by an insulating layer, the insulating layer is wrapped by a braided shield layer, the braided shield layer is wrapped by a restrictive coating, and the periphery of the restrictive coating is provided with a plicated texture. The anti-corrosion and anti-explosion self-temperature-control electric tracing band is simple in structure and good in electromagnetic shielding performance and can be used safely under the high-temperature environment.

Owner:安徽华海特种电缆集团有限公司

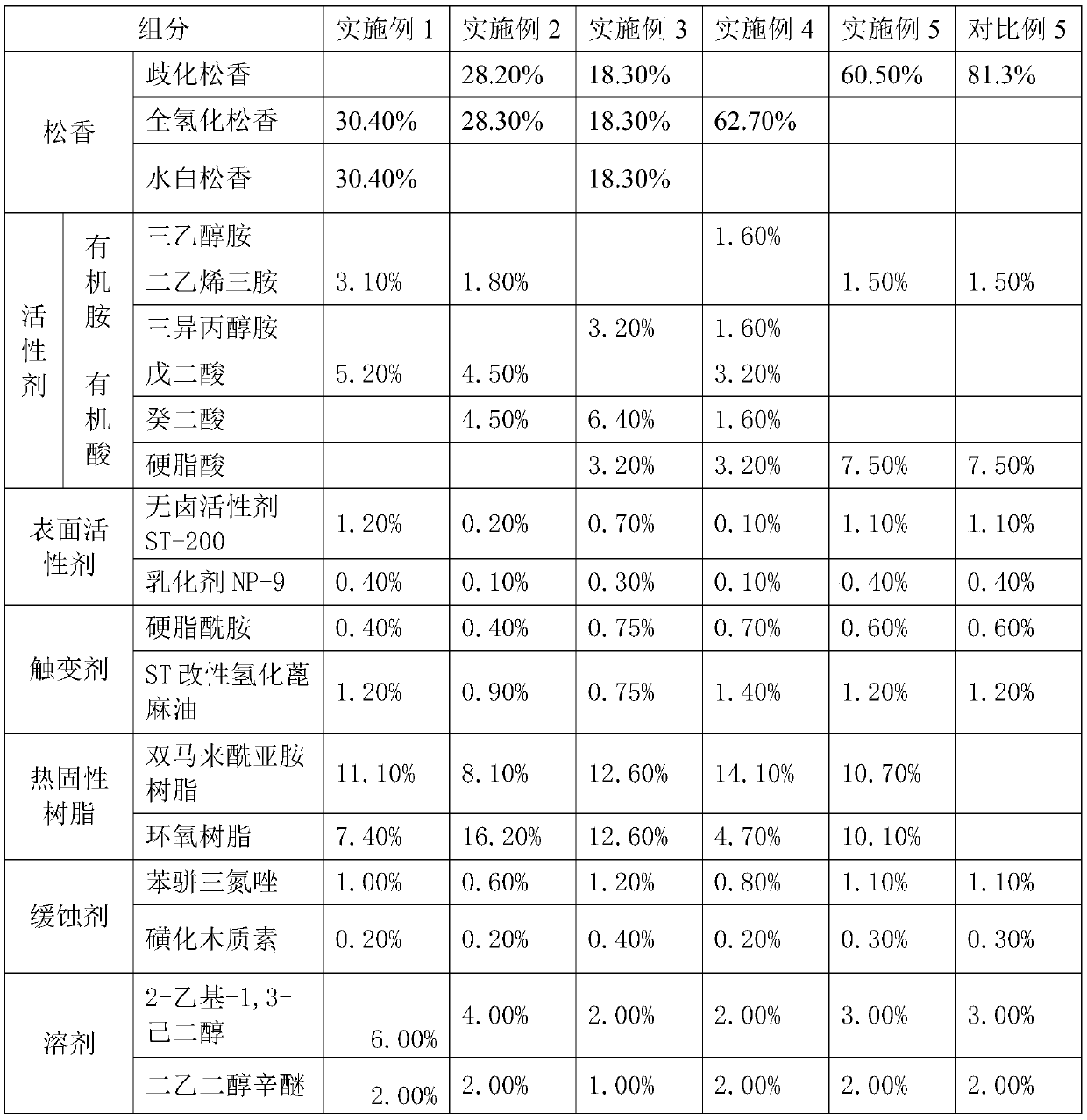

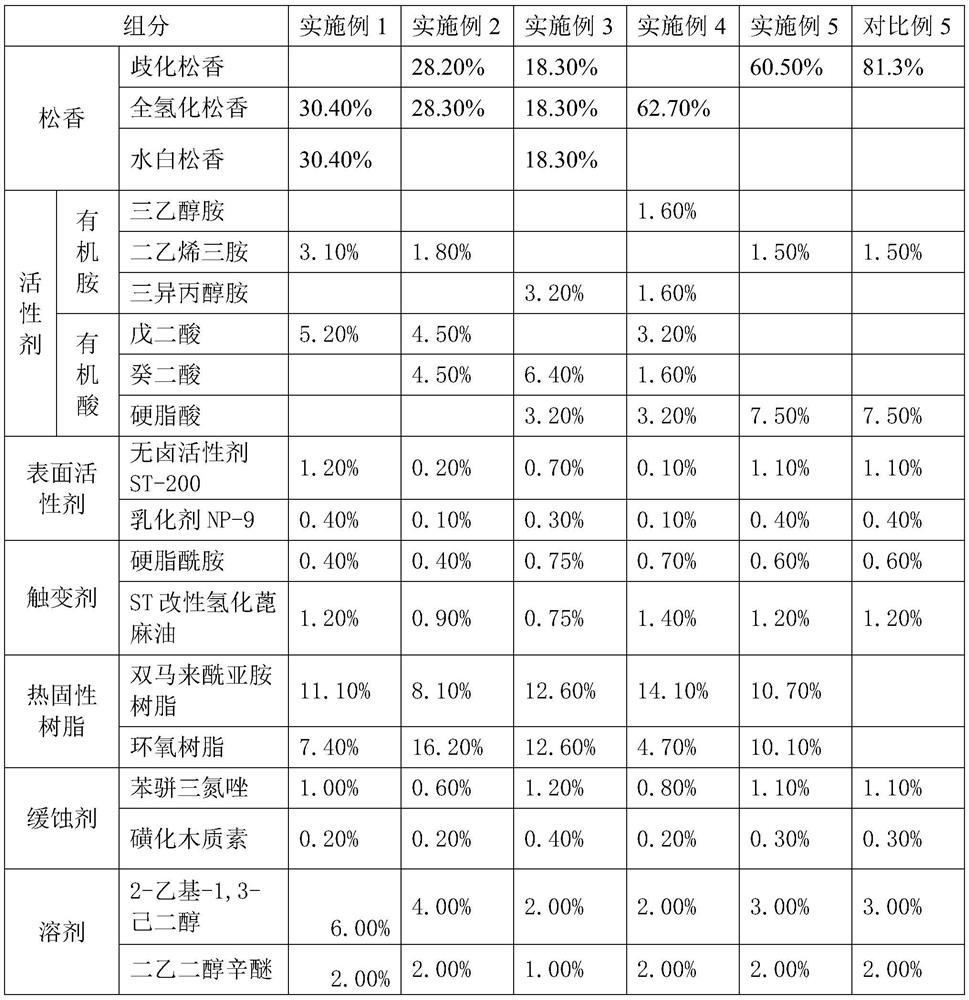

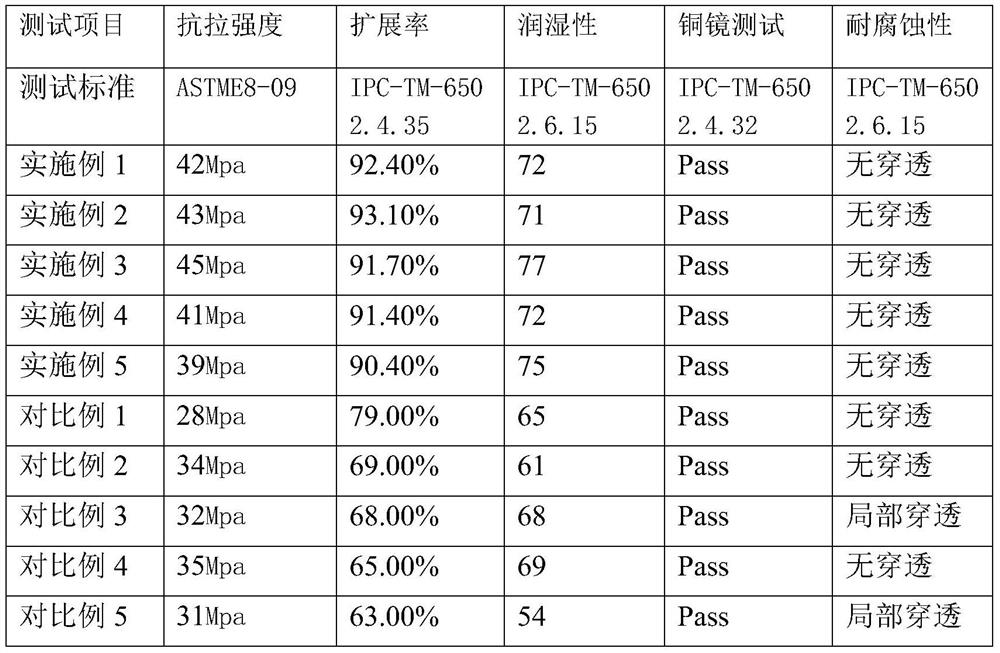

High-weldability environment-friendly superfine solder wire for intelligent manipulator welding and preparation method thereof

ActiveCN111590233AAvoid wastingHigh yieldWelding/cutting media/materialsSoldering mediaLutetiumCerium

The invention discloses a high-weldability environment-friendly superfine solder wire for intelligent manipulator welding and a preparation method thereof. The superfine solder wire comprises 96.9 wt%-98.1 wt% of solder alloy and 1.9 wt%-3.1 wt% of scaling powder, wherein the solder alloy comprises the components of tin, silver, copper, molybdenum, cerium, tellurium and lutetium, by adding the cerium, the structure of the solder can be changed, so that crystal grains are refined, solder joint bridges are reduced, the surface wettability of the solder alloy is changed, and the creep property and the tensile property are improved; the addition of tellurium can improve the corrosion resistance, the wear resistance and the strength of the material, the tensile strength of the solder can be improved, the generation of tin whiskers can be prevented; lutetium has good electrical conductivity and ductility and extremely high activity, and is excellent in effect of improving electric heating performance and oxidation resistance in soldering tin alloy powder, so that tensile strength and toughness of the solder are improved, the wettability of solder wires is good, the tensile strength is excellent, and lead-free and environment-friendly effects are achieved. The superfine solder wire has the advantages of being high in weldability and not prone to core breakage, and high weldability andlead-free environment-friendly development of products are achieved when the superfine solder wire is applied to the high-end application field of intelligent manipulator welding and the like.

Owner:中山翰华锡业有限公司

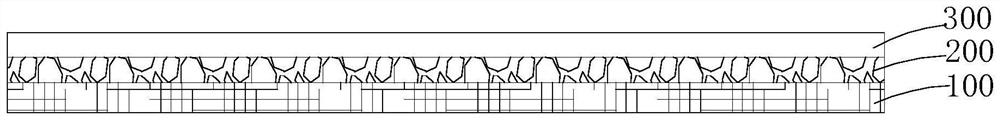

Production process for electro-thermal film encapsulation

InactiveCN106658778AUniform heat conductionAvoid damageOhmic-resistance heatingPower flowComposite film

The invention discloses a production process for electro-thermal film encapsulation, comprising the following steps: S1, making a composite film; S2, pasting an aluminum foil shielding layer, S3, installing a connection terminal; S4, carrying out wiring and insulation; S5, encapsulation; S6, opening sealing; and S7, exhausting and sealing. The beneficial effects are as follows: by adopting the production process for electro-thermal film encapsulation provided by the invention, electro-thermal films can conduct heat evenly, electro-thermal films will not be locally overheated and damaged, and the service life and safety of electro-thermal films are improved; and moreover, an electro-thermal film produced by the process can effectively avoid leakage protector mis-tripping caused by leakage current without a current compensation circuit, has higher electro-thermal performance, can be used in a damp environment, and effectively eliminates the influence of leakage current.

Owner:辽宁百盈碳纤维有限公司

Semiconductor flip-chip bonding packaging heat radiation improved structure

InactiveCN101834163AIncrease cooling areaImprove electrothermal performance and reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectric heatingRadiation

The invention relates to a semiconductor flip-chip bonding packaging heat radiation improved structure comprising a chip, an electrical interconnection material, a lead frame, an encapsulation material and a spring heat radiator, wherein the lead frame is provided with a transmission pin; the electrical interconnection material is implanted at the front face of the chip which is arranged on the transmission pin in an inversion way; the encapsulation material encapsulates the spring heat radiator, the chip, the electrical interconnection material and the lead frame to form an encapsulation body, the periphery of the spring heat radiator is fixed by the encapsulation material, one end of the spring heat radiator is connected with the chip and the other end exposes out of the surface of the encapsulation body so as to radiate the heat of the chip out of the encapsulation body, thereby solving the heat radiation problem for a load-bearing base without a mostly-exposed chip or flip-chip packaging and greatly enhancing electric and thermal performances and reliability of the product.

Owner:NANTONG FUJITSU MICROELECTRONICS

Preparation method of composite carbon-based electrothermal coating

InactiveCN110551435AStable in natureImprove conductivityEpoxy resin coatingsElectrically-conductive paintsPorous carbonCarbon nanofiber

The invention belongs to the technical field of coating preparation, and particularly relates to a preparation method of a composite carbon-based electrothermal coating. The method comprises the steps: taking polyacrylonitrile and zinc acetate as raw materials to obtain porous carbon nanofibers; mixing the porous carbon nanofibers with a mussel mucoprotein liquid, adding catechol oxidase, and carrying out ultrasonic oscillation to obtain reaction filter residues; mixing the reaction filter residues with a silver nitrate solution, and sintering at high temperature to obtain a self-made composite carbon-based filler; and finally, blending and shearing the self-made composite carbon-based filler, resin and other assistants to obtain the composite carbon-based electrothermal coating. Oxidizeddopa groups and unoxidized dopa groups are crosslinked to form a high-molecular reticular polymer which is adsorbed on internal pores and surfaces of the porous carbon nanofibers; the electric heatingcoating has metal ion chelating property, a layer of carbon nano conduction band network is generated between interfaces of metal silver and the porous carbon nanofibers, and the electric conductivity of the composite material is increased. The electric heating coating prepared by the method has the advantages of good electric heating performance, high temperature rise speed, high temperature andwide application prospect.

Owner:罗苗苗

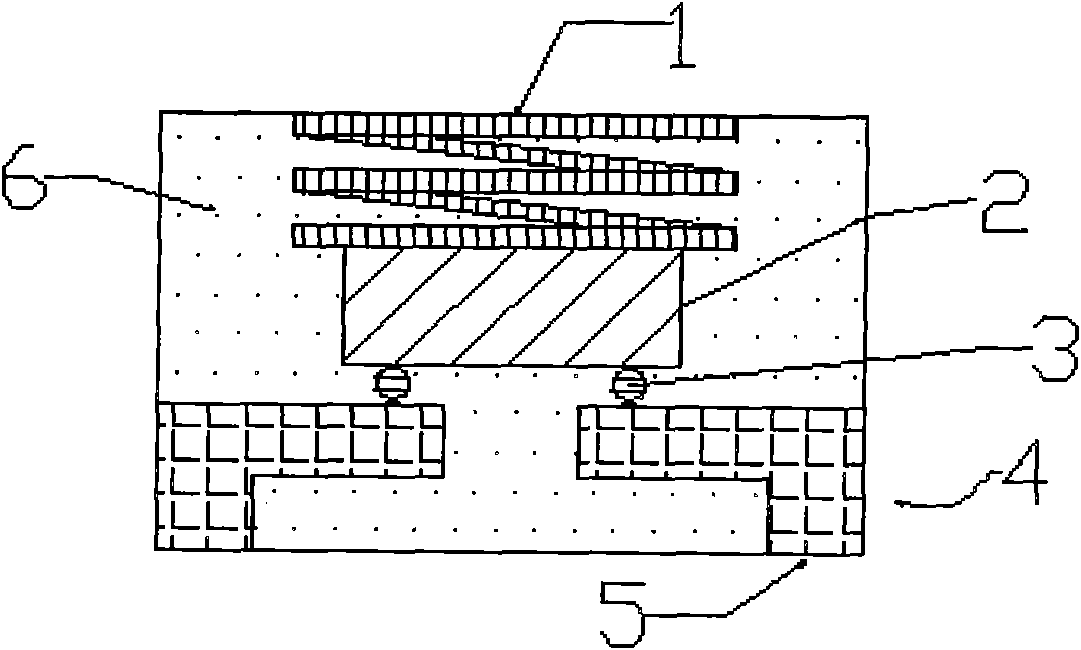

Chip-suspension-type packaging heat dissipation improved structure of semiconductor

ActiveCN101826492BIncrease cooling areaSolve the cooling problemSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageInterconnection

The invention relates to a chip-suspension-type packaging heat dissipation improved structure of a semiconductor, which comprises a chip, metal leads, a bonding material, a lead frame and a plastic package material, and also comprises a spring heat dissipater, wherein transmission pins are arranged on the lead frame, and the chip is arranged on the transmission pins through the bonding material and is in electrical interconnection with the lead frame through the metal leads; the spring heat dissipater, the chip, the metal leads, the bonding material and the lead frame are plastic-packaged bythe plastic package material to form a plastic package body, and the periphery of the spring heat dissipater is fixed by the plastic package material; and one end of the spring heat dissipater is connected with the chip, and the other end thereof is exposed to the surface of the plastic package body to dissipate the heat of the chip out of the plastic package body, thereby solving the heat dissipation difficulties that no exposed chip bears a base or a flip chip is packaged, and greatly improving the electrothermal performance and reliability of products.

Owner:NANTONG FUJITSU MICROELECTRONICS

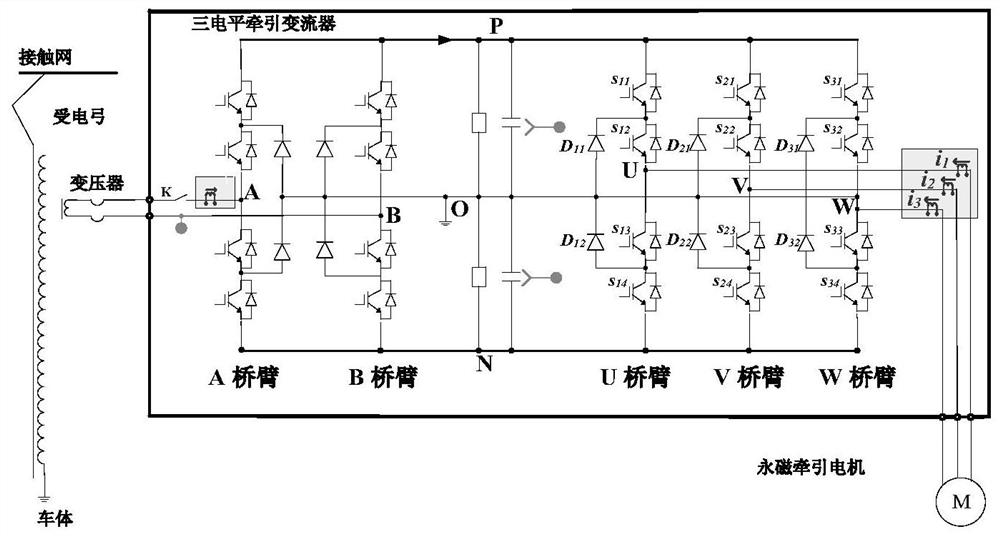

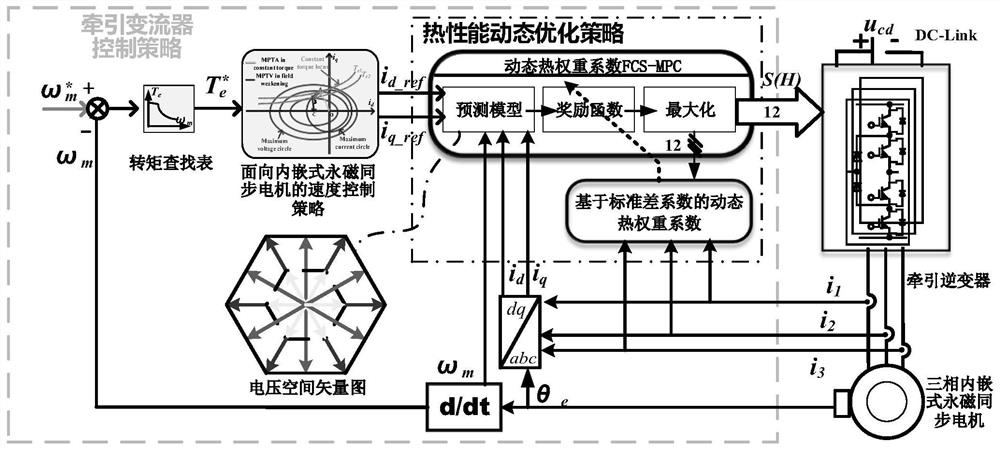

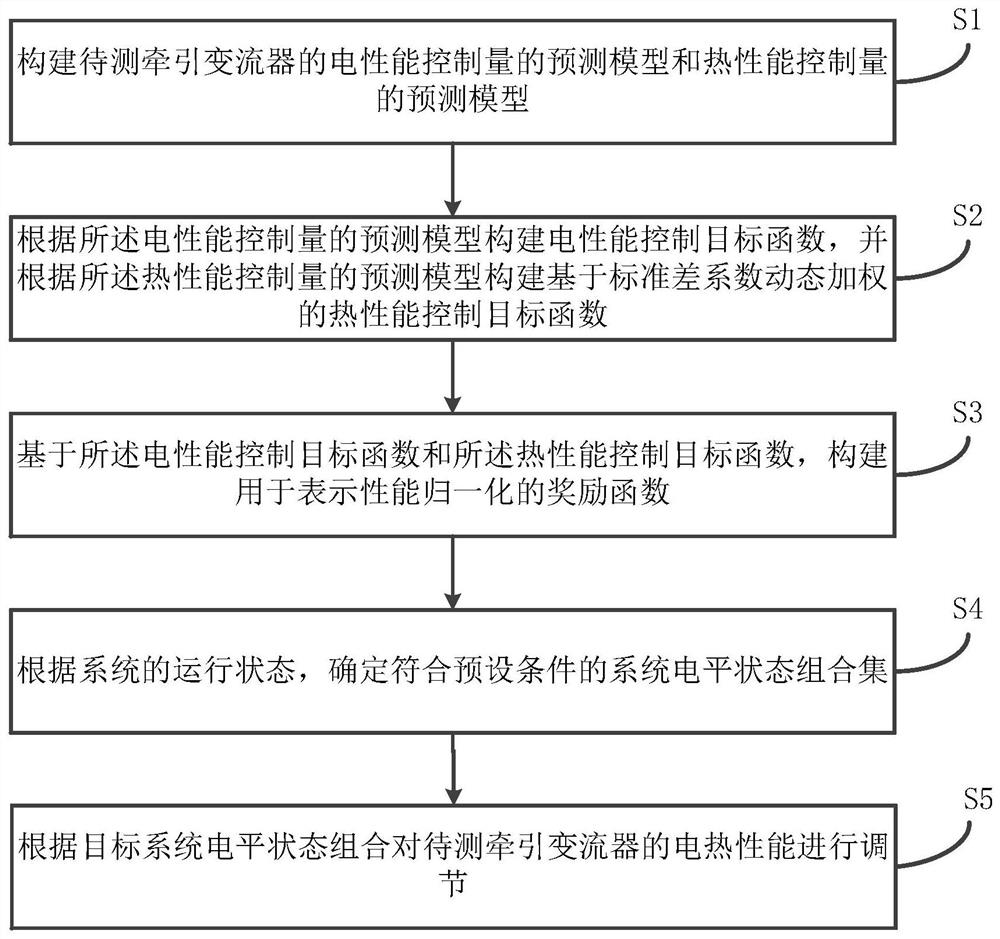

Dynamic optimization control method and system for thermal performance of traction converter

PendingCN113381635AThermal performance optimization controlImprove electrothermal performanceEmergency protective circuit arrangementsAc-dc conversionDynamical optimizationControl objective

The invention relates to the technical field of power electronics, and discloses a dynamic optimization control method and system for thermal performance of a traction converter so as to realize dynamic optimization control of the thermal performance of the traction converter under the normal operation condition and the fault operation condition. The method comprises the following steps: constructing a prediction model of an electrical performance control quantity and a prediction model of a thermal performance control quantity of a to-be-tested traction converter; constructing an electrical performance control objective function according to the prediction model of the electrical performance control quantity, and constructing a thermal performance control objective function based on standard deviation coefficient dynamic weighting according to the prediction model of the thermal performance control quantity; based on the electrical performance control objective function and the thermal performance control objective function, constructing a reward function for representing performance normalization; determining a system level state combination set according with a preset condition according to the operation state of the system; and adjusting the electrothermal performance of the to-be-tested traction converter according to the target system level state combination.

Owner:CENT SOUTH UNIV

Method for producing iron-chromium electrothermal alloy with scrap iron

InactiveCN106801182AEnables recyclingImprove electrothermal performanceProcess efficiency improvementCobaltSilicon

The invention belongs to the technical field of alloy materials, and particularly relates to a method for producing iron-chromium electrothermal alloy with scrap iron. The method includes the steps of matching, smelting, desulfurization and dephosphorization, and refining. According to the method for producing the iron-chromium electrothermal alloy with the scrap iron, cost is low, and the scrap iron can be recycled and treated; moreover, a desulfurizing agent and a dephosphorization agent prepared through the method are used for desulfurization and dephosphorization at a high temperature, and the influence on electrothermal performance of the iron-chromium alloy can be greatly increased; and in the refining process, silicon, molybdenum, vanadium and cobalt at a certain mass ratio are added, and the quick life of iron-chromium-aluminum alloy at the high temperature is prolonged.

Owner:当涂县宏宇金属炉料有限责任公司

An anti-corrosion and explosion-proof self-control temperature electric heating cable

ActiveCN103857080BImprove mechanical propertiesGuaranteed anti-corrosion and explosion-proof performanceHeating element shapesTemperature controlElectricity

The invention discloses an anti-corrosion and anti-explosion self-temperature-control electric tracing band. The anti-corrosion and anti-explosion self-temperature-control electric tracing band comprises a PTC material core which is internally provided with two wires, the PTC material core is wrapped by a single-face metal and plastic composite belt which is internally provided with a drainage wire, the plastic layer of the single-face metal and plastic composite belt faces inwards, and the metal layer of the single-face metal and plastic composite belt faces outwards. The metal and plastic composite belt is wrapped by an insulating layer, the insulating layer is wrapped by a braided shield layer, the braided shield layer is wrapped by a restrictive coating, and the periphery of the restrictive coating is provided with a plicated texture. The anti-corrosion and anti-explosion self-temperature-control electric tracing band is simple in structure and good in electromagnetic shielding performance and can be used safely under the high-temperature environment.

Owner:ANHUI HUAHAI SPECIAL CABLE GRP CO LTD

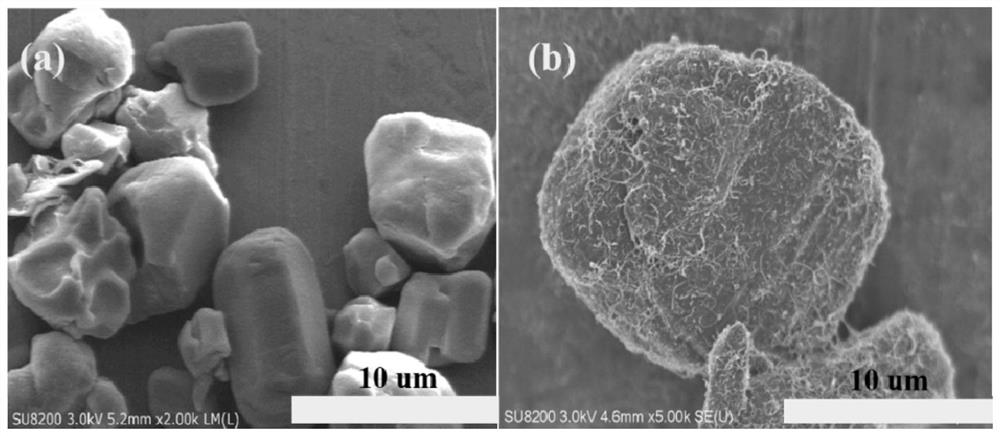

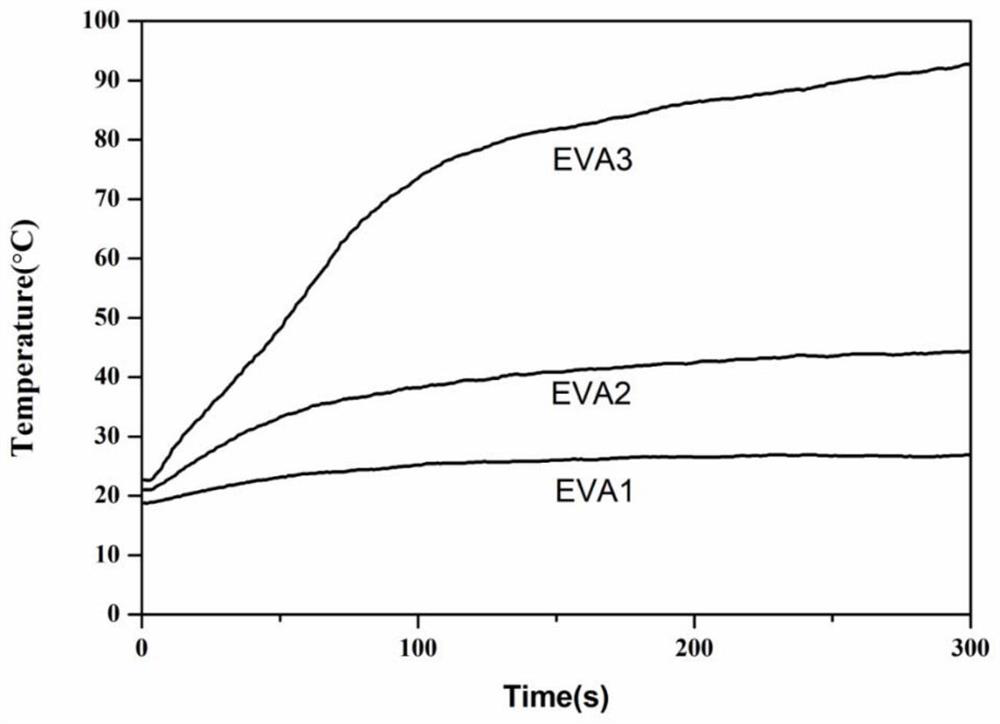

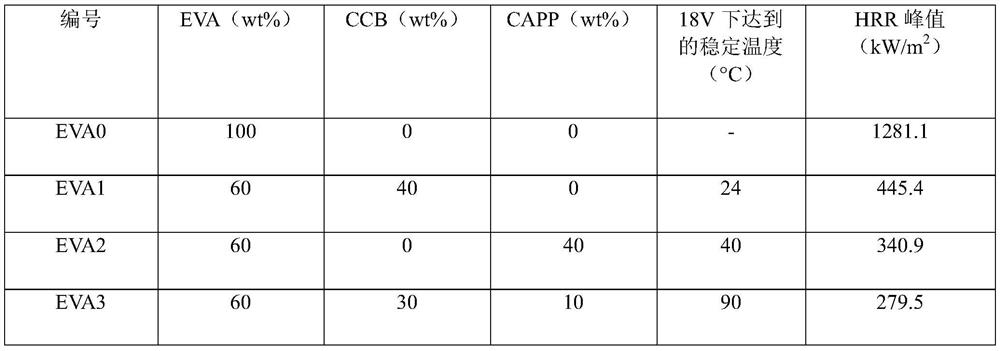

A halogen-free flame retardant low-voltage electric heating film and preparation method thereof

The invention discloses a halogen-free flame-retardant low-voltage electrothermal film and a preparation method thereof. The halogen-free flame-retardant low-voltage electrothermal film is prepared with macromolecules as a matrix and conductive filler and a halogen-free flame retardant wrapped by the conductive filler as raw materials. The preparation method of the electrothermal film is simple; compared with a traditional electrothermal film, the electrothermal film has good electrothermal performance under low voltage below 36V, solves the potential safety hazard of fire hazard when the electrothermal film works at high temperature for a long time, reduces the production cost, and can be widely applied to the fields of physical therapy and health care, building insulation, household heating and the like.

Owner:UNIV OF SCI & TECH OF CHINA

Flip-chip high-heat-radiation spheroidal array encapsulation structure

ActiveCN101840896BIncrease cooling areaSolve the cooling problemSemiconductor/solid-state device detailsSolid-state devicesElectricitySolder ball

The invention relates to a flip-chip high-heat-radiation spheroidal array encapsulation structure, which comprises a chip, an electric interconnection material, a lower filling material, a base plate, a plastic sealing material and a welding ball. A spring heat radiator is also arranged in the encapsulation structure. The electric interconnection material is planted on the front side of the chip, and is inversely arranged on the base plate, and the electric interconnection between the chip and the base plate is realized through the electric interconnection material, the lower filing material fills a gap between the chip and the base plate, the plastic sealing material plastically seals the spring heat radiator, the chip, the electric interconnection material, the lower filling material and the base plate for forming a plastic sealing body, the circumambience of the spring heat radiator is fixed by the plastic sealing material, one end of the spring heat radiator is connected with the chip, and the other end of the spring heat radiator is exposed on the surface of the plastic sealing body for radiating the heat of the chip out of the plastic sealing body. The problem of heat radiation of the encapsulation of carrying bases or inversely arranged chips without exposed metals is solved, and the electric heating performance and the reliability of the products are greatly improved.

Owner:NANTONG FUJITSU MICROELECTRONICS

High-heat-dispersion spherical array encapsulation method

ActiveCN101834150BIncrease cooling areaSolve package heat dissipation problemsSemiconductor/solid-state device detailsSolid-state devicesElectricityBiomedical engineering

The invention relates to a high-heat-dispersion reverse solder spherical array encapsulation method which comprises the following steps of: implanting a chip into a substrate by using a binding material; pasting a spring radiator on the chip; electrically connecting the chip and the substrate by a metal lead; plastically encapsulating the spring radiator, the chip, the metal lead, the binding material and the substrate with a plastic encapsulating material to form a plastic encapsulated body; and fixing the periphery of the spring radiator by the plastic encapsulating material, wherein one end of the spring radiator is connected with the chip, and the other end is exposed out of the surface of the encapsulated body so that the heat of the chip is dispersed out of the encapsulated body. The invention solves the problems of heat dispersion in encapsulation without an exposed metal carrier plates and greatly improves the electrothermal performance and the reliability of the product.

Owner:NANTONG FUJITSU MICROELECTRONICS

Energy-saving rapid electric cooker heating method and electric cooker thereof

PendingCN111184433AHeating up fastImprove electrothermal performanceWarming devicesCooking vessel constructionsThermodynamicsEngineering

The invention relates to an energy-saving rapid electric cooker heating method and an electric cooker thereof. In order to solve the problems of low efficiency and slow heating in the prior art, threeor more than three open-loop circular electric heating tubes are arranged under a pot body in an aluminum-coated manner to annularly heat the bottom of the pot in a plurality of circles inside and outside, the pot body heats the liquid contained in the pot at intervals through the temperature difference between the inside and the outside of a vertical pipe by placing the vertical pipe, and the temperature difference interval heating is characterized by placing the vertical pipe which can be freely taken and placed, of which the height is smaller than the vertical depth of a lower opening inner cavity circle in the pot, and the inner cavity tangent circle diameter is equal to or larger than that of a second electric heating pipe from outside to inside in the middle of the bottom of the pot. The vertical pipe is circular, and the upper openings of the vertical pipe are waved openings which are alternately distributed in a circumferential concave-convex sequence. The energy-saving rapidelectric cooker heating method and the electric cooker thereof have the advantages of being high in electric heating efficiency, fast in temperature rise and beneficial to improving food quality.

Owner:李文

A kind of method for preparing w-cu system gradient composite material by casting method

Owner:WUHAN UNIV OF TECH

A kind of method for preparing alumina-dispersed copper by external oxidation

ActiveCN114045411BImprove performanceEvenly controlled ingredientsProcess efficiency improvementAluminium oxidesCopper alloy

Owner:XIAN REFRA TUNGSTEN & MOLYBDENUM

A high-weldable environment-friendly ultra-fine solder wire for intelligent manipulator welding and its preparation method

ActiveCN111590233BImprove wettabilityHigh tensile strengthWelding/cutting media/materialsSoldering mediaLutetiumCerium

The invention discloses a high-weldable environment-friendly ultra-fine solder wire for intelligent manipulator welding and a preparation method thereof. Silver, copper, molybdenum, cerium, tellurium and lutetium, the addition of cerium can change the structure of the solder, thereby refining the grains, reducing solder joint bridging, changing the surface wettability of the solder alloy, improving creep properties, tensile Characteristics, the addition of tellurium can improve the corrosion resistance, wear resistance and strength of the material, can improve the tensile strength of the solder and prevent the generation of tin whiskers, lutetium has good conductivity and ductility, and has a strong activation in solder alloys The powder has an excellent effect on improving the electrothermal performance and anti-oxidation performance, improves the tensile strength and toughness of the solder, has good solder wire wettability, excellent tensile strength and is lead-free and environmentally friendly. This application has the advantages of high solderability and not easy to break the core , High solderability and lead-free environmental protection development of products when applied to high-end application fields such as intelligent manipulator welding.

Owner:中山翰华锡业有限公司

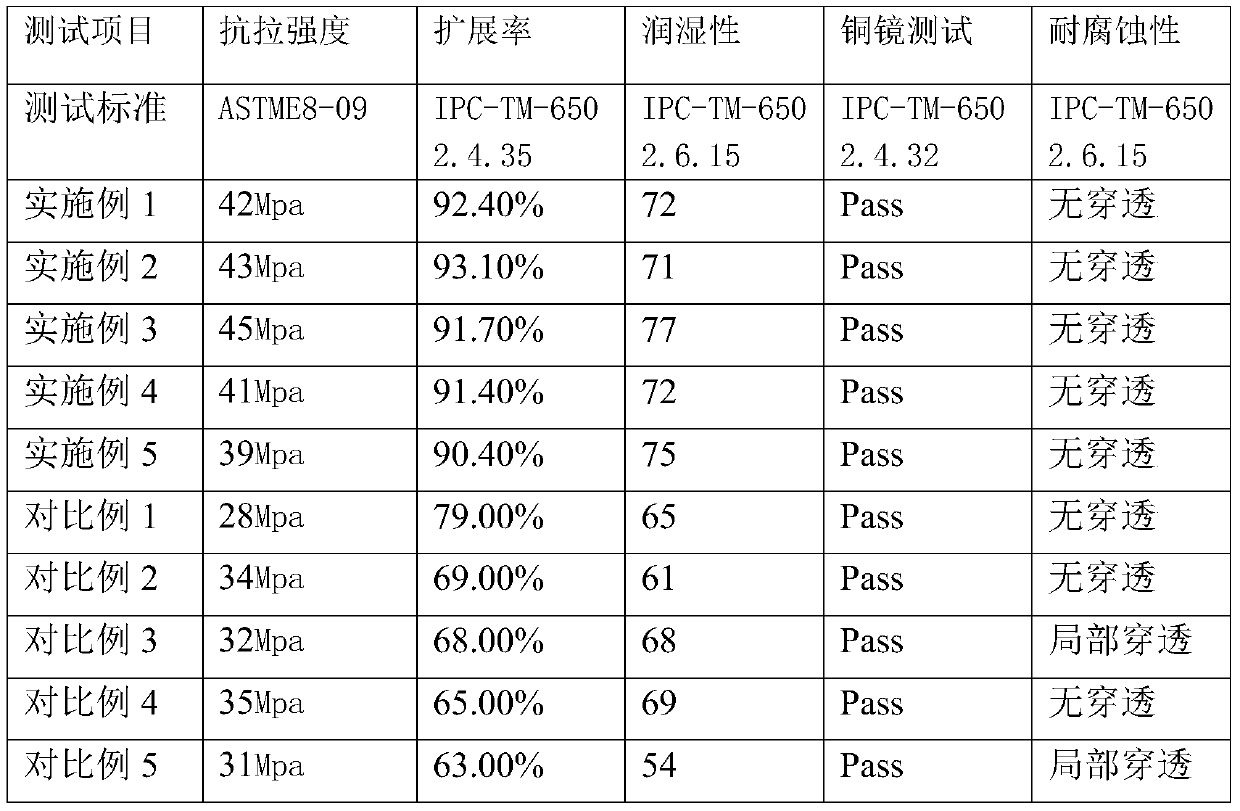

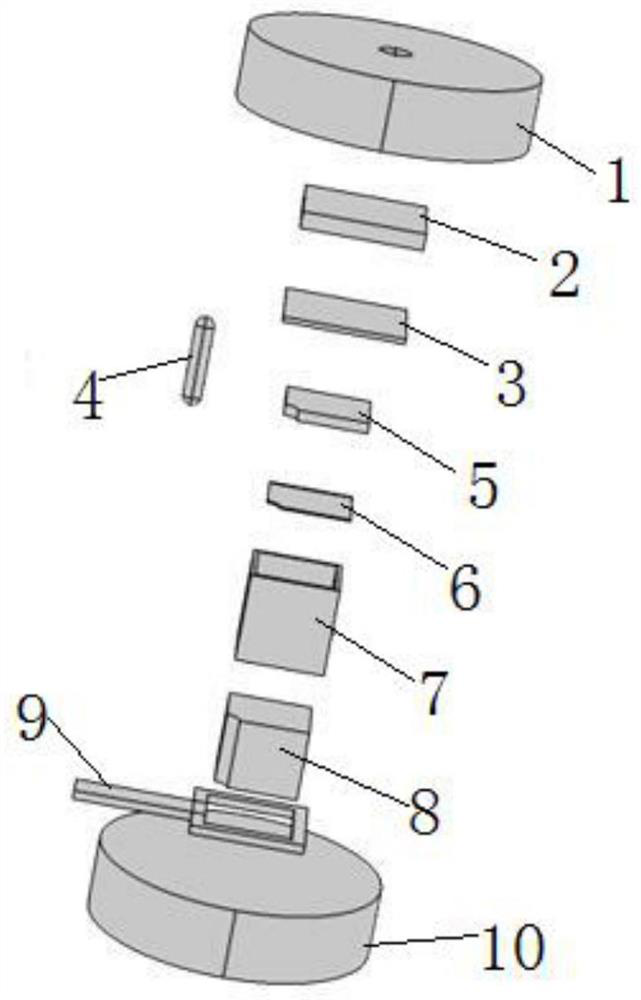

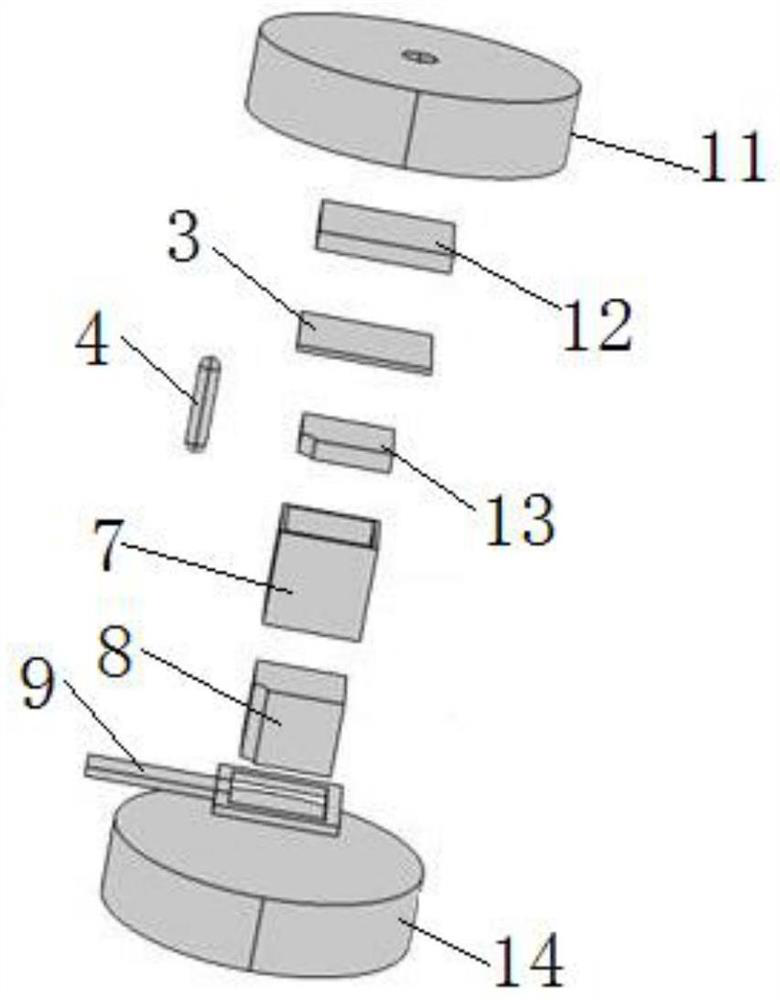

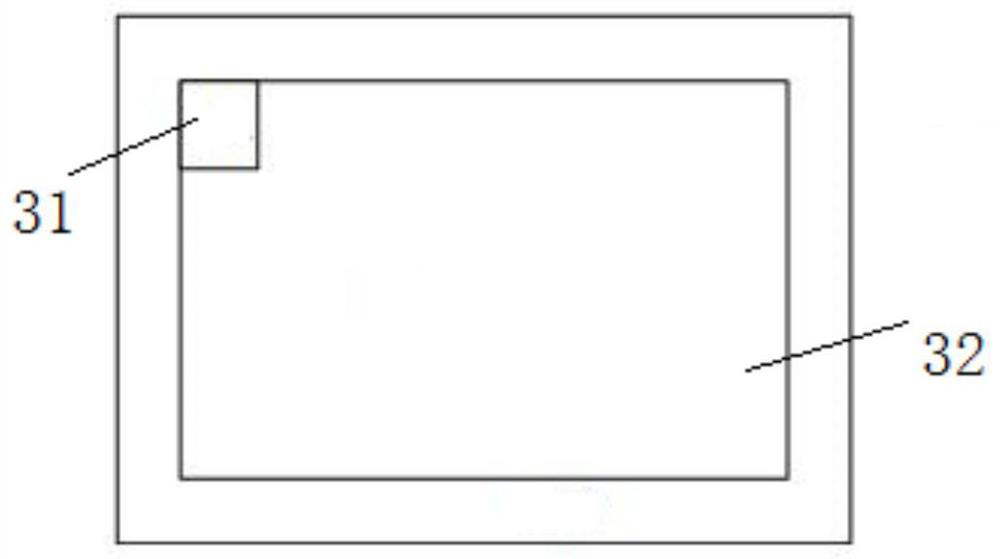

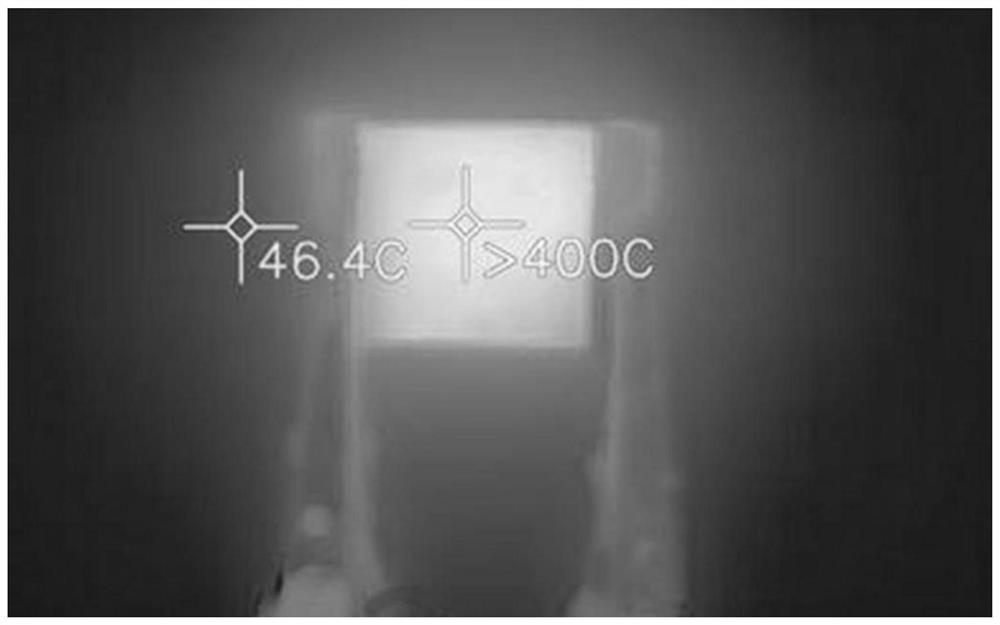

Crimping type IGBT power module based on gradient functional composite material packaging

PendingCN112908955AReduce the difficulty of package integrationImprove electrothermal performanceSemiconductor/solid-state device detailsSolid-state devicesFunctional compositeElectric heating

The invention relates to a crimping type IGBT power module based on gradient function composite material packaging, an IGBT sub-module between a collector metal layer and an emitter metal layer comprises a collector gradient function composite material layer, an IGBT power chip, an emitter gradient function composite material layer, a copper pedestal and a grid PCB which are successively crimped from top to bottom, a packaging shell support is sleeved outside the crimped IGBT sub-module, and gate spring ejector pins are placed in gaps of the crimped emitter gradient function composite material layer and the copper pedestal. The thermal expansion coefficients of the collector gradient function composite material layer, a collector metal layer, the collector surface of the IGBT power chip, the emitter gradient function composite material layer, the emitter surface of the IGBT power chip and the copper pedestal are matched. The problems that in an existing crimping type IGBT power module, thermal expansion coefficients between the IGBT power chip and a packaging material assembly are not matched, so that the electric heating contact performance of an assembly interface is reduced, the heat dissipation efficiency is reduced, and the service life of a device is shortened are solved.

Owner:CISDI ENG CO LTD +1

Self-annealing graphene self-supporting high-temperature electrothermal film and preparation method thereof

ActiveCN112291868AGood for mass manufacturingReduce energy consumptionHeater elementsGrapheneGraphiteHeat treated

The invention discloses a self-annealing graphene self-supporting high-temperature electrothermal film and a preparation method thereof. The preparation method comprises the following steps: ultrasonically dispersing electrochemical stripping graphene containing functional groups on the surface to obtain graphene dispersion liquid; carrying out suction filtration, blade coating or printing on thegraphene dispersion liquid to form a graphene film, and drying to obtain a self-supporting graphene film; carrying out heat treatment on the self-supporting graphene film to obtain a self-supporting graphene film subjected to heat treatment; and adding an electrode to the self-supporting graphene film subjected to heat treatment to obtain an electrothermal film, and electrifying to heat the electrothermal film to 350-400 DEG C to obtain the self-annealing graphene self-supporting high-temperature electrothermal film. The prepared self-annealing graphene self-supporting high-temperature electrothermal film is uniform in heating temperature, high-temperature cyclic heating shows good stability, the preparation method is simple in procedure and low in cost, and large-scale industrial preparation and application are easy.

Owner:LANZHOU UNIVERSITY

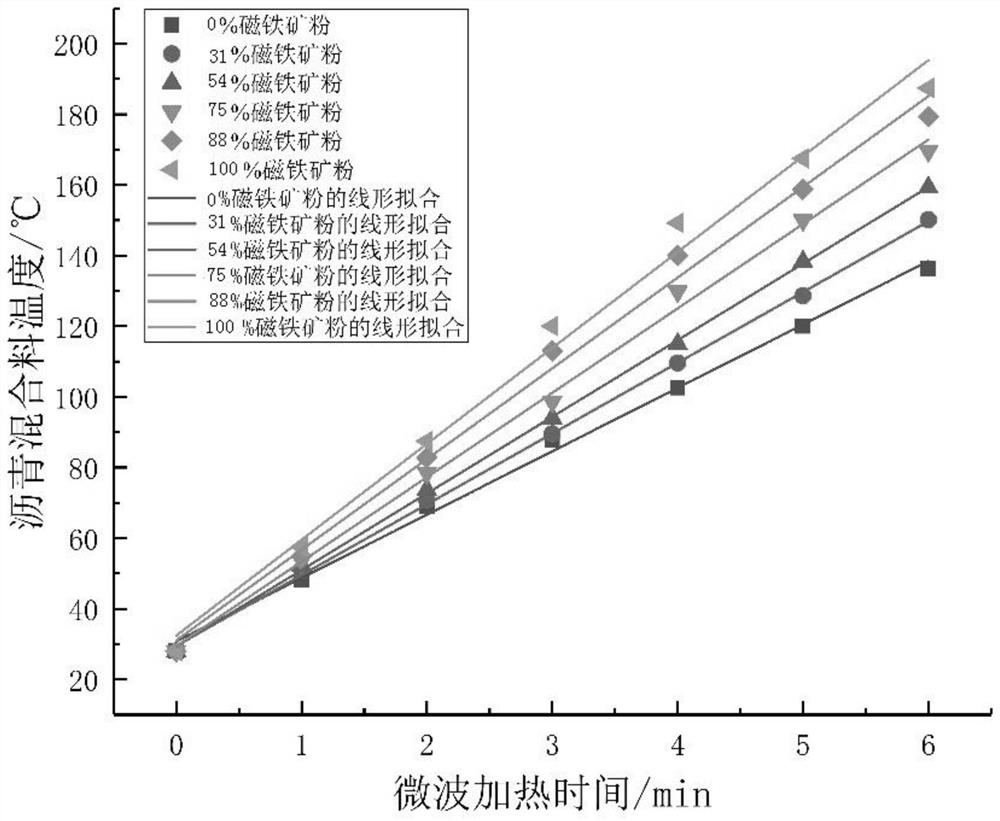

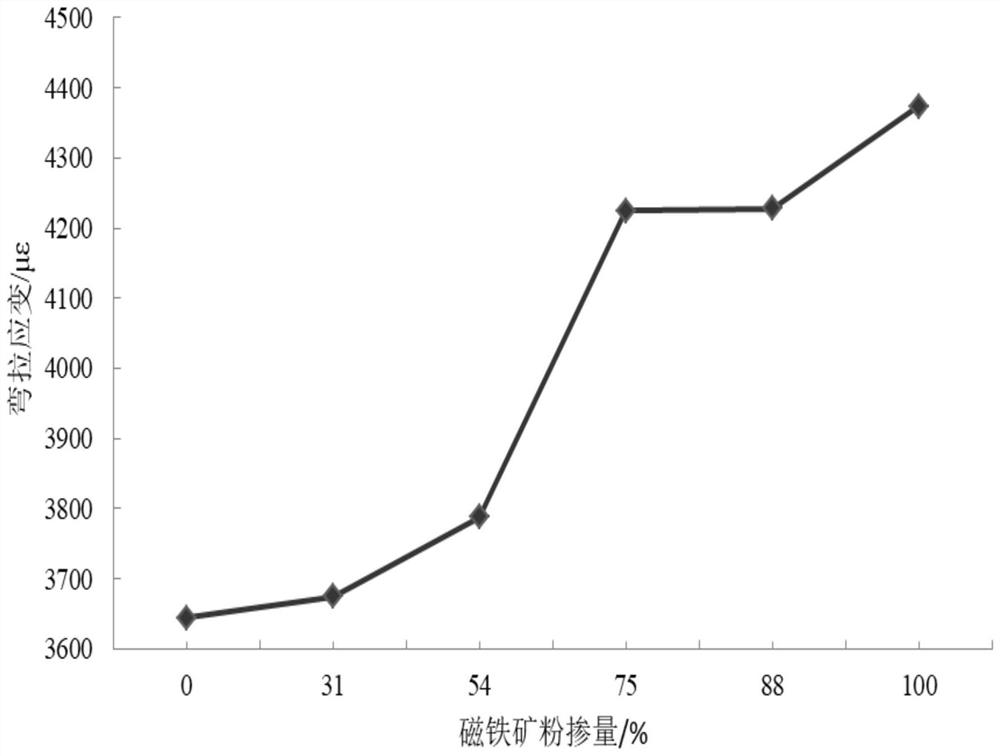

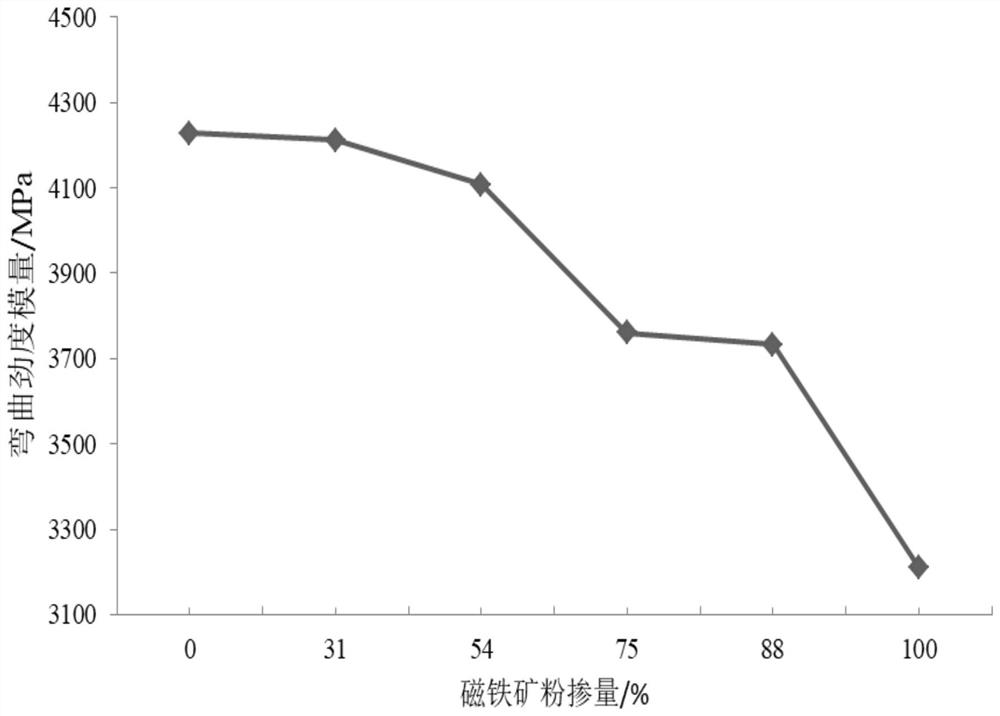

Asphalt mixture for improving microwave absorption efficiency and preparation method thereof

Owner:CHANGAN UNIV

A kind of graphene conductive paste and preparation method thereof

ActiveCN108257710BGood dispersionAvoid defects such as reunionsNon-conductive material with dispersed conductive materialCable/conductor manufactureConductive pasteReactive diluent

The application relates to the field of conductive pastes, in particular to a graphene conductive paste. The graphene conductive paste comprises the following components, by weight: 1 to 10 parts of epoxy-functionalized graphene, 4 to 15 parts of epoxy resin, 2 to 6 parts of epoxy-modified siloxane, 2 to 6 parts of epoxy reactive diluents, and 0.1 to 0.8 parts of latent curing agents. Furthermore,the graphene conductive paste also includes 5 to 20 pars, by weight, of conductive black modified with a silane coupling agent. In addition, the application also provides a method for preparing the graphene conductive paste. The method includes: carrying out epoxy functionalization of graphene powder; carrying out epoxy modification of siloxane; carrying out mixing and stirring of all components;and carrying out conductive black modification. According to the graphene conductive paste provided by the application, the high dispersibility of graphene and good adhesion of the conductive paste are realized; and with the conductive black, the amount of graphene is reduced and the cost is lowered.

Owner:SHENZHEN HOVERBIRD ELECTRONICS TECH CO LTD

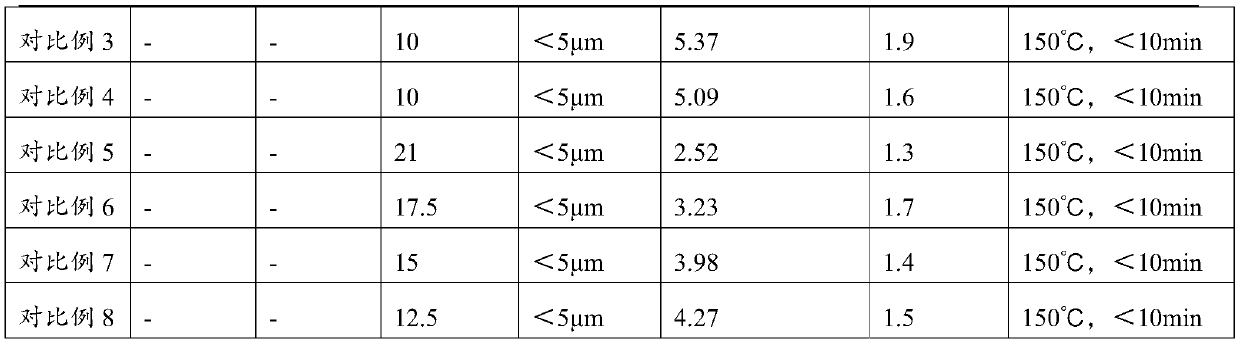

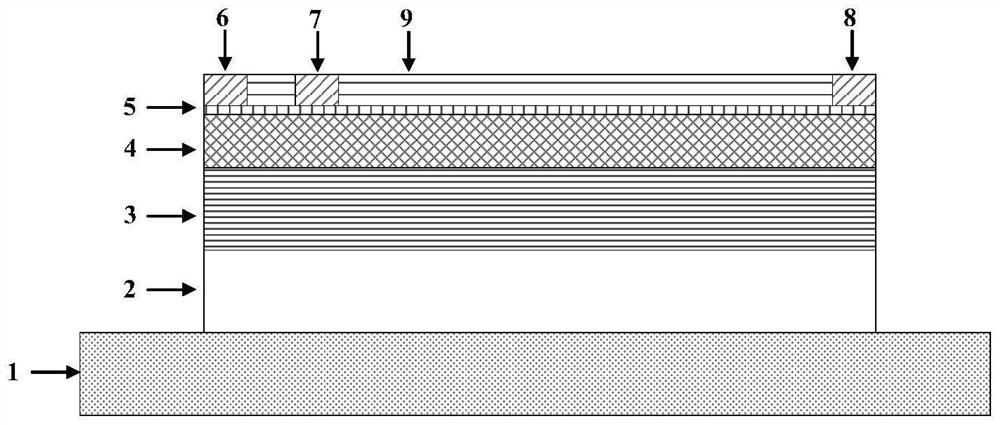

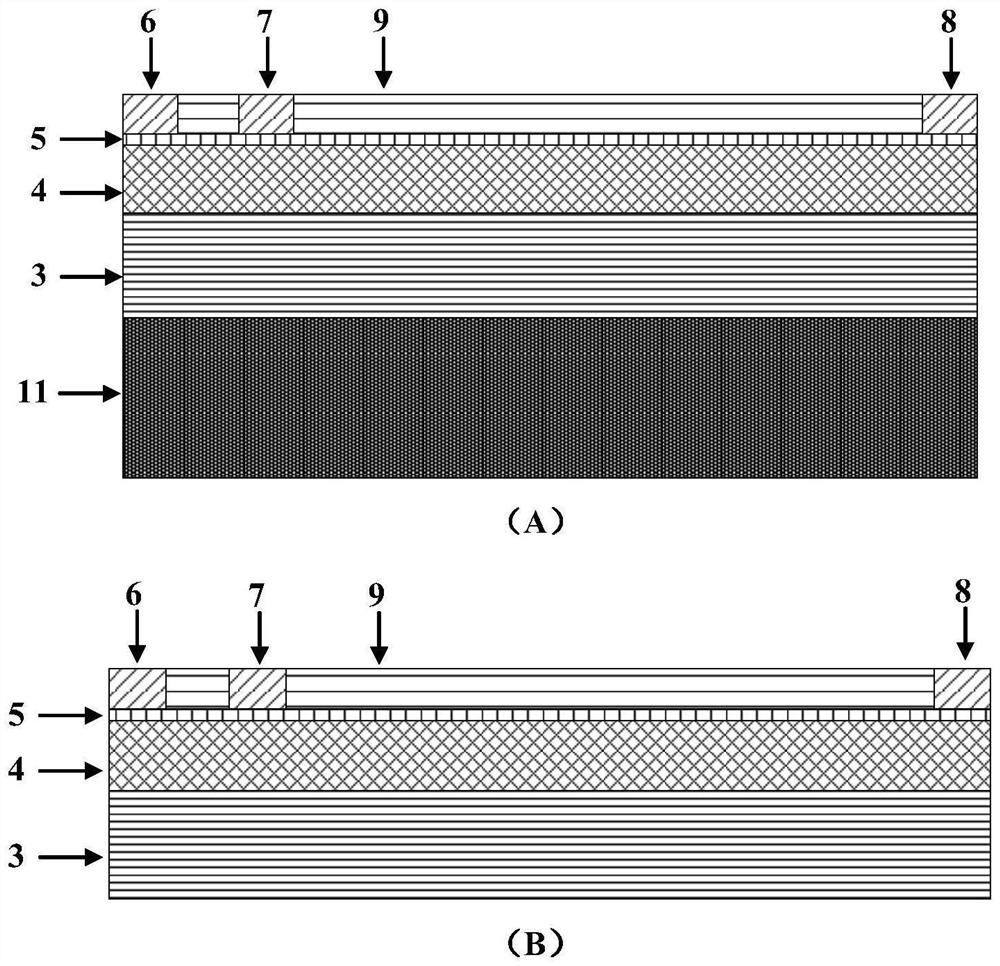

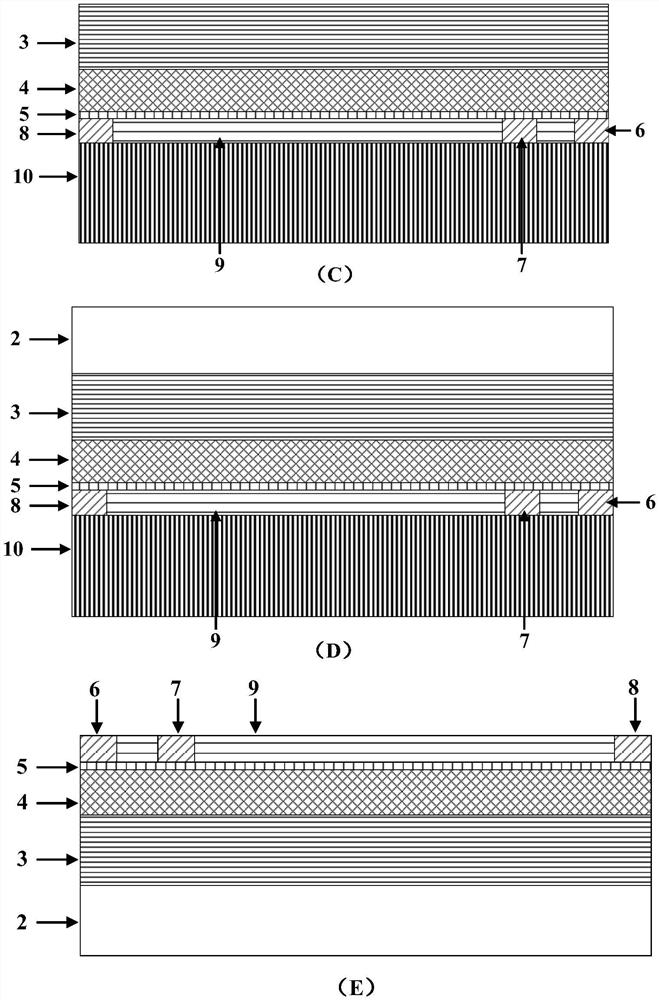

Silicon-based GaN HEMT heat dissipation enhanced packaging structure and preparation method thereof

PendingCN114864519AAvoid agglomeration effectImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesMetallic electrodeEngineering

The invention discloses a silicon-based GaN HEMT (High Electron Mobility Transistor) heat dissipation enhanced packaging structure and a preparation method thereof, and belongs to the field of information materials and devices, the structure takes a substrate (1) as a carrier and is connected with a high heat conduction layer (2) in a chip bonding mode, the upper part of the high heat conduction layer (2) is connected with a GaN HEMT, and the lower part of the high heat conduction layer (2) is connected with a silicon-based GaN HEMT. The GaN HEMT sequentially comprises a GaN buffer layer (3), a GaN channel layer (4), an AlGaN barrier layer (5), a medium passivation layer (9) and a metal electrode from bottom to top. According to the prepared structure, the low-heat-conductivity silicon substrate of the silicon-based GaN HEMT is peeled off, the high-heat-conductivity material is connected with the substrate, the heat accumulation effect caused by the silicon-based material is avoided, the heat dissipation capacity of the high-power-density GaN HEMT chip is improved, the structure is compatible with an existing advanced packaging structure and a packaging heat dissipation technology, and the manufacturing cost is reduced. The electric heating performance and the reliability of the packaged chip can be remarkably improved, and the high value is achieved.

Owner:NANJING UNIV OF POSTS & TELECOMM +1

Improved method for semi-conductor flip-chip bonding package cooling

ActiveCN101840868BIncrease cooling areaSolve the cooling problemSemiconductor/solid-state device detailsSolid-state devicesImproved methodLead frame

The invention relates to an improved method for semi-conductor flip-chip bonding package cooling, which comprises the following steps that: a chip with electrical interconnecting material planted on the front side is arranged on a transmission tube pin of a lead frame upside down; a spring radiator is attached on the back side of the chip; plastic sealed material is used for sealing the spring radiator, the chip, the electrical interconnecting material and the lead frame to form a plastic sealed body, and the periphery of the spring radiator is fixed by the plastic sealed material; and one end of the spring radiator is connected with the chip and the other end thereof is exposed on the surface of the plastic sealed body so as to release the heat of the chip out of the plastic sealed body; and the improved method for semi-conductor flip-chip bonding package cooling solves the difficulty problem of cooling of some packages without exposed chip bearing base or flip chip, and greatly improves the electric heating performance and the reliability of the product.

Owner:NANTONG FUJITSU MICROELECTRONICS

Heat exchanger of air conditioner

InactiveCN1123758CImprove heat transfer performanceImprove electrothermal performanceEvaporators/condensersStationary conduit assembliesPlate heat exchangerHeat sink

A heat exchanger for an air conditioner having a plurality of parallel heat exchanging tubes passing through flat fins perpendicular thereto, the flat fins being arranged in parallel to each other at predetermined intervals, and each heat exchanging tube having fluids flowing inside therethrough, the heat exchanger comprising a plurality of louvers radially arranged around the tube, each louver being opened in flow direction of the air currents, such that the air currents flowing into the front and rear surfaces is turbulent around the tube, and first and second beads formed, respectively, before and behind the heat exchanging tubes in flow direction of the air currents, thereby enlarging a whole surface area of the flat fins, and reinforcing the flat fins, by which there is provided the turbulence and mixture of the air currents, further improving the heat transfer effect and reducing the air dead region around the heat exchanging tube. Also, the continuity of the heat transfer from the tube into other places can be guaranteed, with the improved heat transfer. Moreover, the beads provide the enlargement of the surface area of the flat fin and improved reinforcing thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

Electric heating fabric based on copper nanowires and preparation method thereof

PendingCN114657793AEnhanced electrothermal performanceGood electrical conductivityOhmic-resistance heatingTextiles and paperCopper nanowiresElectric heating

According to the electric heating fabric based on the copper nanowires and the preparation method of the electric heating fabric based on the copper nanowires, the electric heating fabric based on the copper nanowires comprises a base material layer and a protective layer which are arranged in a stacked mode, the base material layer is loaded with the copper nanowires, and / or a copper nanowire functional layer is arranged between the base material layer and the protective layer. According to the copper nanowire electric heating fabric, the protection layer is arranged on the base material layer loaded with the copper nanowires or the protection layer is arranged on the copper nanowire functional layer, the protection layer is used for isolating air, the copper nanowires can be protected against oxidation, the copper nanowires can be prevented from falling off from the base material layer, and therefore the electric heating performance of the copper nanowire electric heating fabric is enhanced.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com