Heat exchanger of air conditioner

A technology for air conditioners and heat exchangers, applied in heat exchange equipment, air conditioning systems, evaporators/condensers, etc., can solve the problems of inability to improve heat transfer efficiency and decline in electrical and thermal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An embodiment of the present invention will be described in detail below based on the drawings.

[0023] The structures in the drawings that are the same as the existing structures use the same names and symbols, and detailed descriptions thereof are omitted.

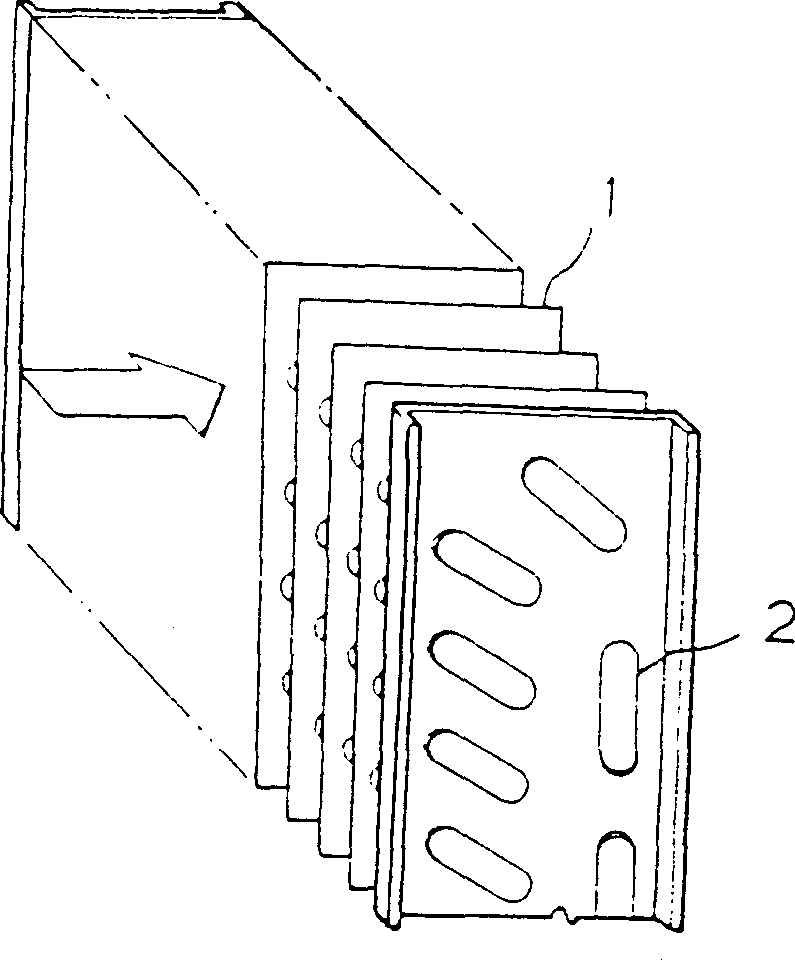

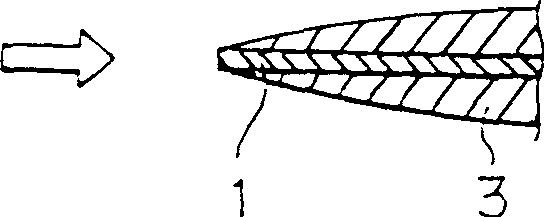

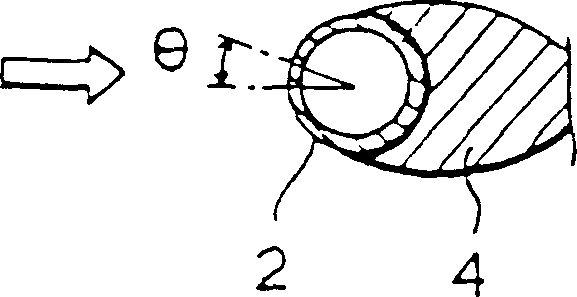

[0024] Figure 6 The reference number 20 in is a group of slit-type cutting fins. The group of slit-type cutting fins 20 are radially arranged on the flat plate heat sink 1 with respect to the upper and lower sides of the plurality of electric heating tubes 2 and the like, with the opening facing The upper and lower sides of the electric heating pipe 2 are surrounded by a certain base plate 21 in the direction of the air flow, so that the warm fluidization and mixing of the air flow flowing through the back and the surface of the plurality of flat fins 1 are reduced in the above-mentioned multiplication. The dead zone is generated at the rear of the electric heating tube 2, and the overall electric heating performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com