Electric heating fabric based on copper nanowires and preparation method thereof

A copper nanowire, electrothermal technology, applied in electrothermal devices, ohmic resistance heating, electrical components, etc., can solve the problems of reduced electrothermal performance, reduced electrical conductivity, easy to fall off, etc., to achieve enhanced electrothermal performance, good stability, and rapid heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The second major aspect of the present application also proposes a preparation method of the above-mentioned copper nanowire electrothermal fabric, the preparation method comprising the following steps:

[0048] The pretreatment step of the base material layer 100 is to pretreat the base material layer 100 to prepare the pretreated base material layer 100;

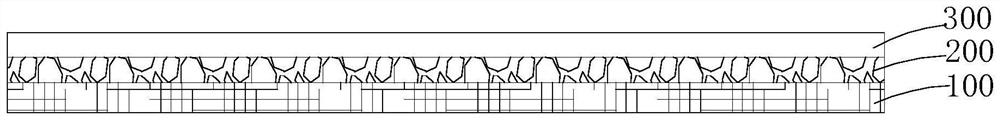

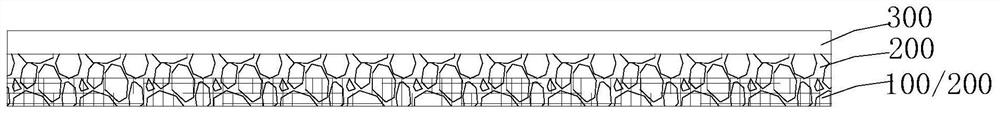

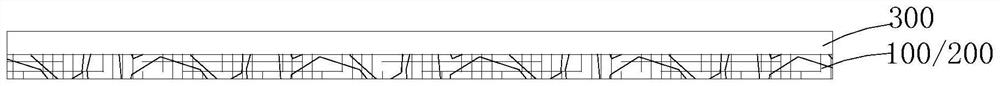

[0049] The copper nanowire loading step is to impregnate the pretreated substrate layer 100 with the copper nanowire dispersion, then dry and / or form a copper nanowire functional layer 200 on one side of the pretreated substrate layer 100 to obtain a semi-finished copper nanowire electric heating fabric;

[0050] The protective layer 300 is prepared by forming the protective layer 300 on either side of the copper nanowire electric heating fabric semi-finished product or forming the protective layer 300 on the side of the copper nanowire electric heating fabric semi-finished product adjacent to the copper nanowire fun...

Embodiment 1

[0098] 1. Preparation of n-hexane dispersion of copper nanowires:

[0099] A copper chloride deionized aqueous solution with a mass concentration of 8 g / L and a glucose deionized aqueous solution with a mass concentration of 12 g / L were prepared respectively. First, 50 mL of glucose deionized aqueous solution was added dropwise to 50 mL of copper chloride deionized aqueous solution to prepare a first mixed solution, and then 25 mL of glycerol analytical reagent was added dropwise to the first mixed solution to prepare a second mixed solution. solution, then add 20 mL of analytically pure oleylamine reagent dropwise to the above-mentioned second mixed solution to obtain a third mixed solution, and then add 200 μL of analytically pure oleic acid reagent to the above-mentioned third mixed solution to obtain a fourth mixed solution. mixture. Finally, the fourth mixed solution was placed at a temperature of 120° C. to react for 4 hours. After the solid-liquid mixture obtained aft...

Embodiment 2

[0109] The preparation method of the electrothermal fabric in this example is the same as that in Example 1, except that the loading amount of copper nanowires on the cotton fabric is 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com