Energy-saving rapid electric cooker heating method and electric cooker thereof

A heating method and technology of an electric heating pot, applied to heating devices, the structure of cooking utensils, cooking utensils, etc., can solve the problems of low electric heating efficiency and slow heating up, achieve high electric heating efficiency, fast heating up, and improve food quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

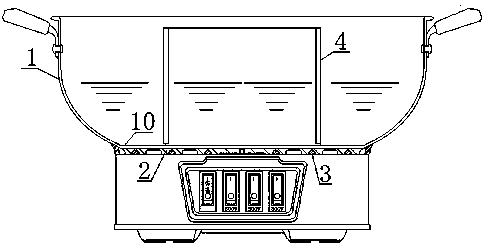

[0020] Embodiment one, such as figure 1 As shown, the present invention’s energy-saving and rapid electric pan heating method and its electric heating pan are that the bottom 10 of the pot body 1 is coated with aluminum 2, and three or more than three open-loop circular electric heating tubes 3 are arranged inside and outside the bottom 10 of the pan. Multi-circle annular heating, the pot body 1 is heated by placing the vertical pipe 4 to heat the liquid in the pot at intervals of the temperature difference between the inside and outside of the vertical pipe 4, the configuration of the pot body 1: when in use, it can be placed in the middle of the bottom 10 of the pot freely The height of the pick-and-place is less than the vertical depth of the pot body, and the diameter of the inner cavity circle (or inner cavity tangent circle) is equal to or greater than the circular straight vertical tube 4 of the diameter of the second electric heating tube 3 from outside to inside. The ...

Embodiment 2

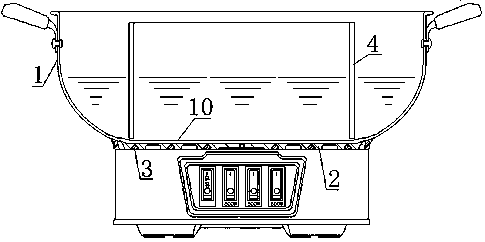

[0021] Embodiment two, such as figure 2 As shown, the difference between the energy-saving and rapid electric pan heating method and the electric heating pan of the present invention and the first embodiment is that the vertical pipe 4 is a vertical pipe with a thinner, lower, and thicker diameter in the middle. The diameter reduction of the standpipe 4 is gradually excessive diameter reduction. The upper thicker and lower thicker are the thin and small bell mouths of the upward section and the large and thick bell mouths of the downward section respectively. The gradual excessive diameter reduction means that at least the vertical tangent line of the side wall of the diameter reduction area of the standpipe is arc-shaped.

Embodiment 3

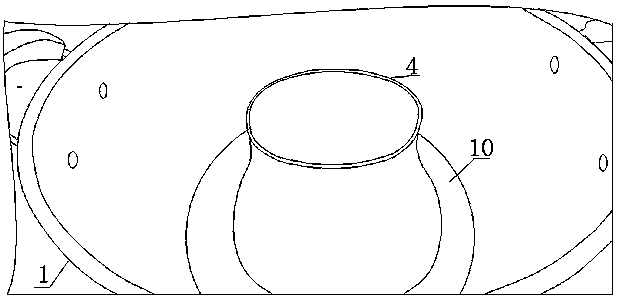

[0022] Embodiment three, such as image 3 As shown, the difference between the present invention's energy-saving and rapid electric pan heating method and the electric heating pan thereof is that the top of the pan bottom 10 corresponding to the vertical pipe 4 has a conical annular slope shape with a low inside and a high outside. The hole on the end face of the lower opening of the vertical pipe can be in the shape of a conical ring with a corresponding high inner height and outer lower concave upper face. The diameter of the cavity circle or the tangential circle of the cavity at the bottom of the vertical pipe 4 can also be equal to or greater than the diameter of the first electric heating tube 3 from outside to inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com