A halogen-free flame retardant low-voltage electric heating film and preparation method thereof

An electric heating film and low-voltage technology, which is applied in the field of halogen-free flame-retardant low-voltage electric heating film and its preparation, can solve problems that threaten human life safety and economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

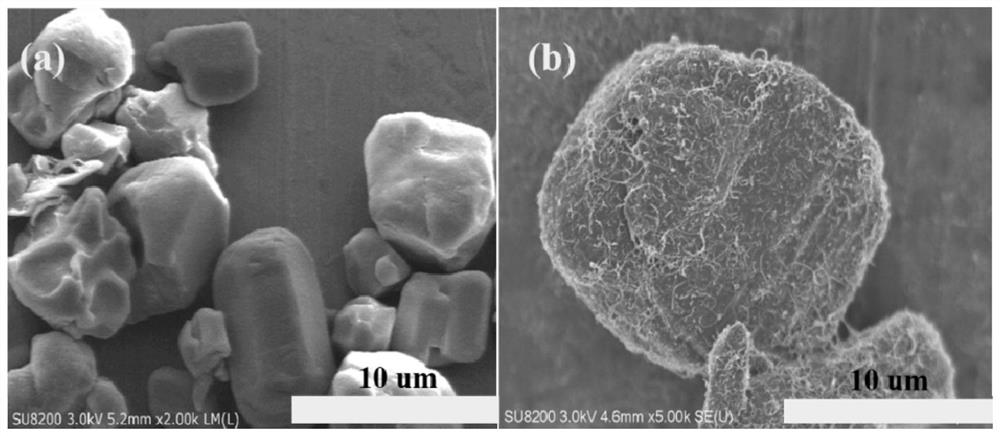

[0030] The halogen-free flame-retardant low-voltage electric heating film synthesized in this example is based on a polymer material, and the conductive filler and the halogen-free flame retardant wrapped by the conductive filler are used synergistically, and finally the halogen-free flame-retardant low-voltage electric heating film prepared by mechanical processing membrane. Among them, ethylene-vinyl acetate is used as the polymer matrix, ammonium polyphosphate is used as the halogen-free flame retardant, and carbon nanotubes are used as the conductive filler for wrapping the halogen-free flame retardant. The halogen-free flame-retardant low-voltage electric heating film is prepared according to the following steps:

[0031] 1. At 45°C, add 4.75g of ammonium polyphosphate to a three-necked flask equipped with a stirrer, reflux condenser and dry nitrogen, and disperse it into a mixed solvent of 300ml of water and ethanol (wherein water and ethanol The volume ratio is 1:2), th...

Embodiment 2

[0041] The halogen-free flame-retardant low-voltage electric heating film synthesized in this example is based on a polymer material, and the conductive filler and the halogen-free flame retardant wrapped by the conductive filler are used synergistically, and finally the halogen-free flame-retardant low-voltage electric heating film prepared by mechanical processing membrane. Among them, polyethylene octene copolymer is used as the polymer matrix, inorganic aluminum hypophosphite is used as the halogen-free flame retardant, and graphene nanosheets are used as the conductive filler for wrapping the halogen-free flame retardant. The halogen-free flame-retardant low-voltage electric heater is prepared according to the following steps membrane:

[0042] 1. At 60°C, add 4.75g of inorganic aluminum hypophosphite to a three-necked flask equipped with a stirrer, reflux condenser and dry nitrogen, and disperse it into a mixed solvent of 300ml of water and ethanol (wherein water and eth...

Embodiment 3

[0051] The halogen-free flame-retardant low-voltage electric heating film synthesized in this example is based on a polymer material, and the conductive filler and the halogen-free flame retardant wrapped by the conductive filler are used synergistically, and finally the halogen-free flame-retardant low-voltage electric heating film prepared by mechanical processing membrane. Among them, low-density polyethylene is selected as the polymer matrix, aluminum hydroxide is selected as the halogen-free flame retardant, and titanium carbide is selected as the conductive filler for wrapping the halogen-free flame retardant. The halogen-free flame-retardant low-voltage electric heating film is prepared according to the following steps:

[0052] 1. At 45°C, add 9.5g of aluminum hydroxide to a three-necked flask equipped with a stirrer, a reflux condenser, and dry nitrogen, and disperse it into a mixed solvent of 300ml of water and ethanol (wherein water and ethanol The volume ratio is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com