Dynamic optimization control method and system for thermal performance of traction converter

A technology for traction converters and control methods, applied in the direction of conversion of AC power input to DC power output, output power conversion devices, electrical components, etc., can solve the problems of neglecting the thermal stress of traction converters, unbalanced thermal stress, Problems such as the loss of symmetry in the topology of the converter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

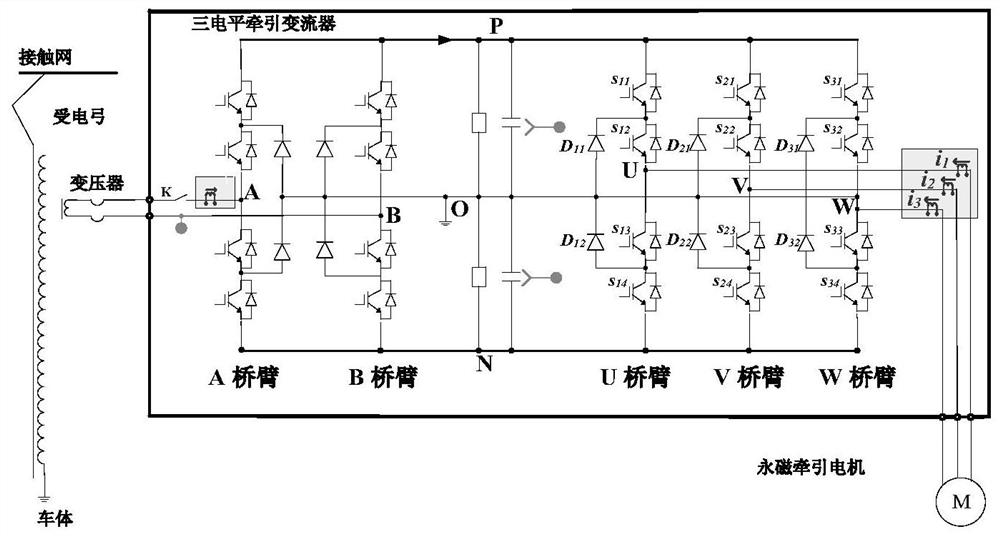

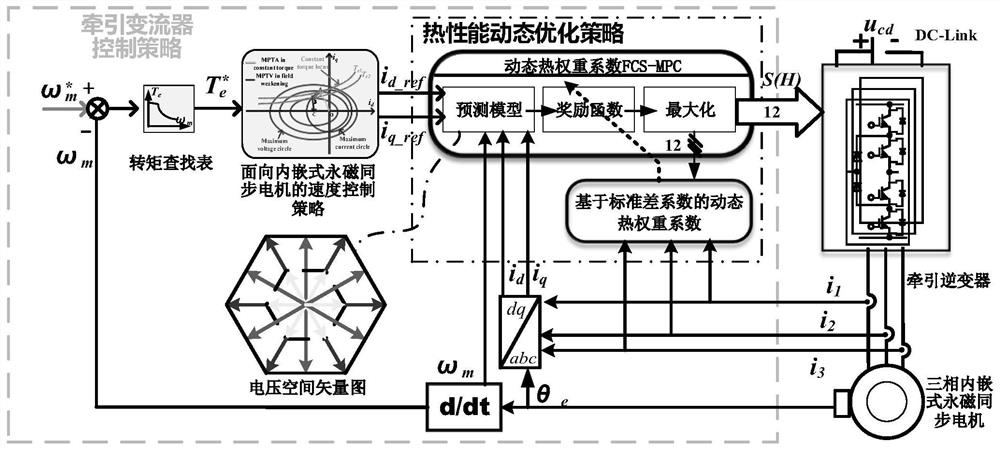

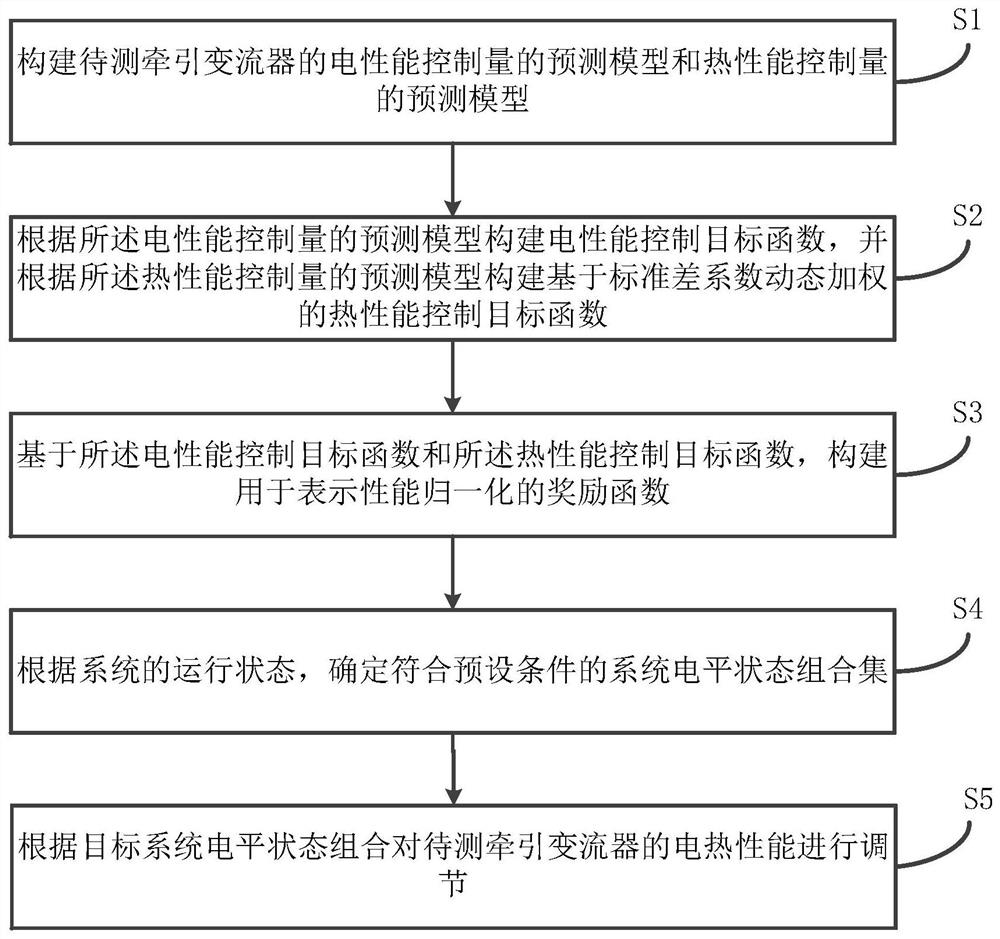

[0036] This embodiment refers to a three-level traction converter system for a permanent magnet high-speed train. The traction converter can be further divided into a single-phase three-level rectifier and a three-phase three-level inverter. The specific topology is as follows figure 1shown. This embodiment will take the thermal performance dynamic optimization control of a three-phase three-level traction inverter as an example for illustration. The traction three-level inverter system adopts a speed-current double closed-loop control structure, and the outer control loop is a speed loop. According to The given value of the electromagnetic torque of the system can be obtained through the look-up table of the speed feedback; then, the maximum torque-to-current ratio (MTPA) and the full-speed embedded permanent magnet synchronous The motor control strategy obtains the given values of the motor stator d-axis current and stator q-axis current, and uses this as the given input o...

Embodiment 2

[0129] Corresponding to the above method embodiments, this embodiment provides a traction converter thermal performance dynamic optimization control system, including a memory, a processor, and a computer program stored in the memory and operable on the processor, the processor executes The computer program realizes the steps of the above method.

[0130] To sum up, the methods and systems respectively disclosed in the above two embodiments of the present invention realize the traction transformer under normal operation of the integrated system by intelligently regulating the heat generated by the power module in the traction converter and the current path and voltage in the traction converter. The dynamic optimization control of the thermal performance of the traction converter integrates the enhancement of the thermal performance of the traction converter and the improvement of the thermal performance of the traction converter under system fault operation. The method is easy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com