LED driver controller, LED driver and LED driving method

A technology of LED driver and controller, which is applied in the field of LED driver controller, can solve problems such as burning, uneven heat distribution, and temperature rise of LED driver controller, so as to solve the problem of temperature rise and reduce uneven heat distribution or heat loss. cumulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

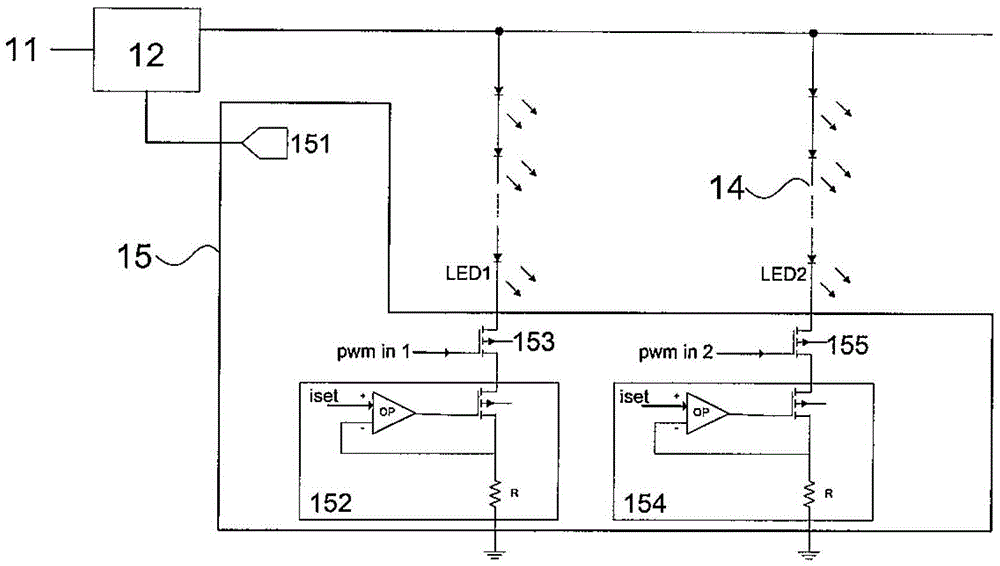

[0032] Down figure 2 Details the uneven heat distribution or build-up of heat on the LED driver controller due to manufacturing variations between LEDs when scaling across many LED strings.

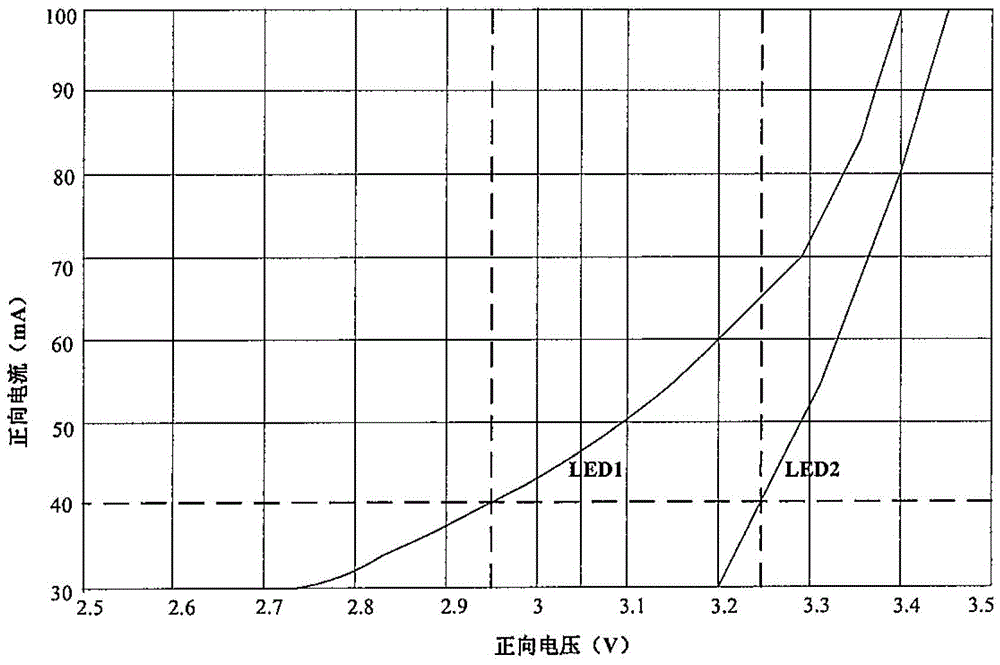

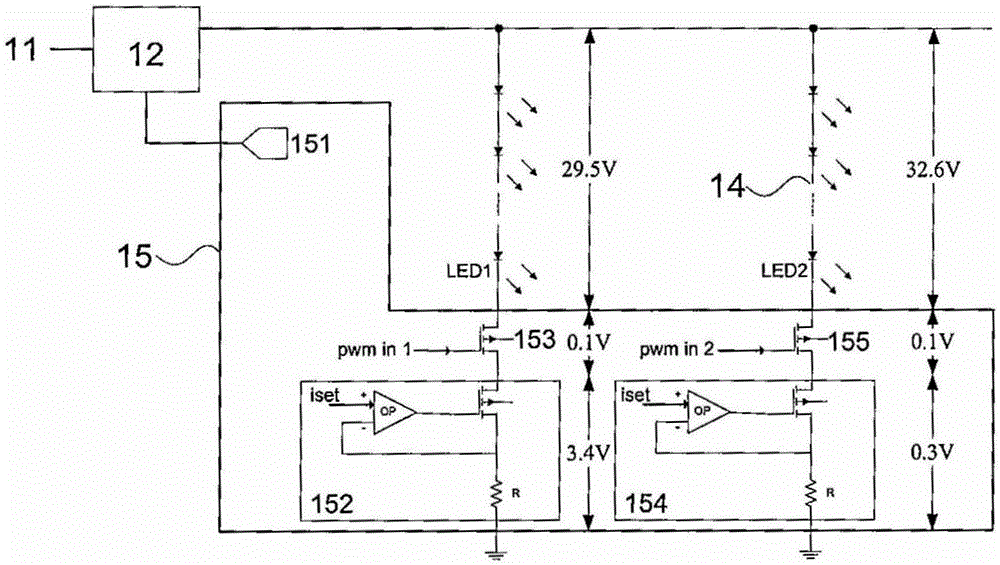

[0033] figure 2 is a schematic representation of the exponential relationship between the voltage and current of two different LEDs according to an embodiment of the present invention Figure 1 ,Such as figure 2 As shown, assuming a current setting of 40mA in each LED string, LED1 must operate at a forward voltage drop of approximately 2.95 volts, while LED2 must operate at a forward voltage drop of approximately 3.26 volts. Therefore, there is a difference of approximately 0.31 volts between the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com