Coating compositions for inorganic casting molds and cores, comprising formic acid esters, and use thereof

A molding material and rubber technology, applied in the direction of coating, core, casting mold, etc., can solve problems such as low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

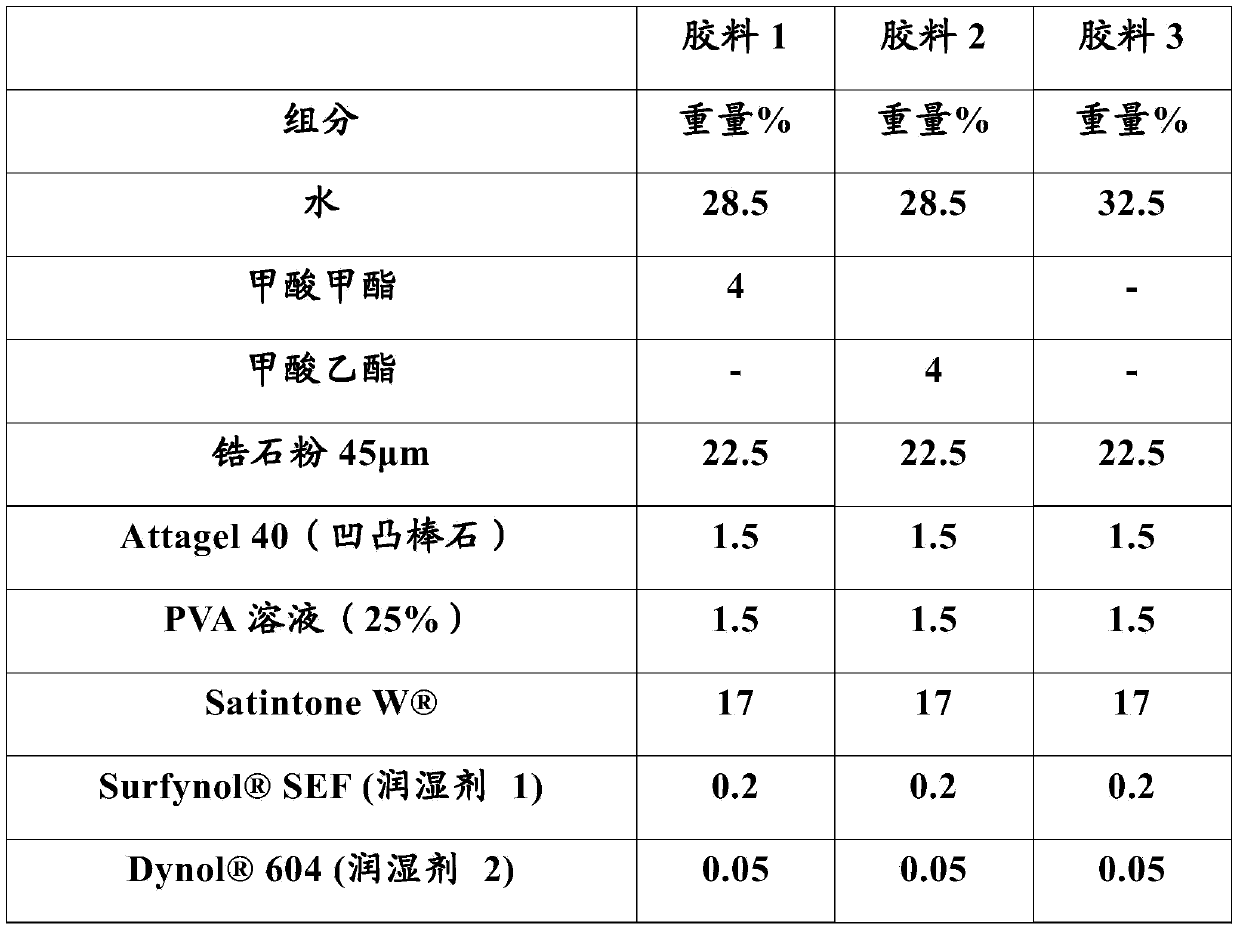

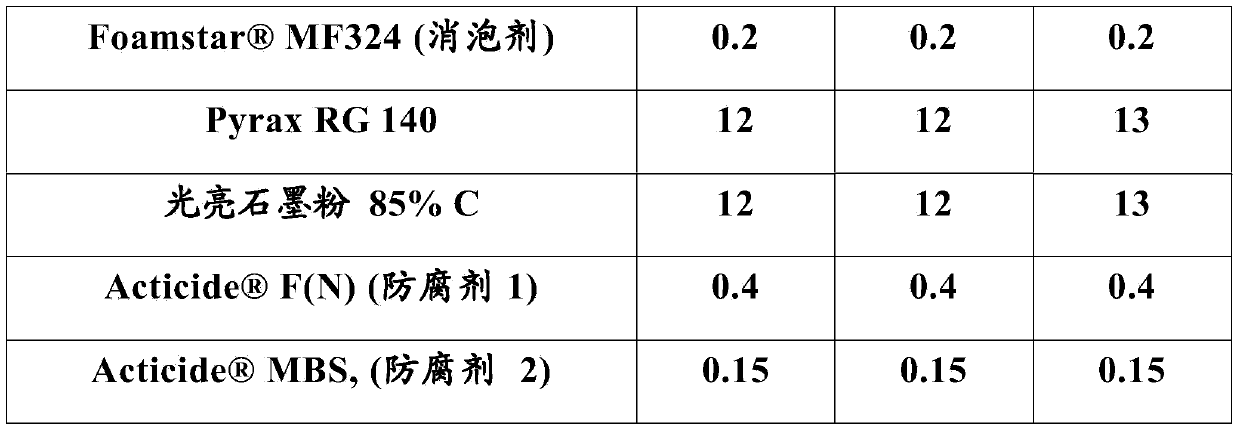

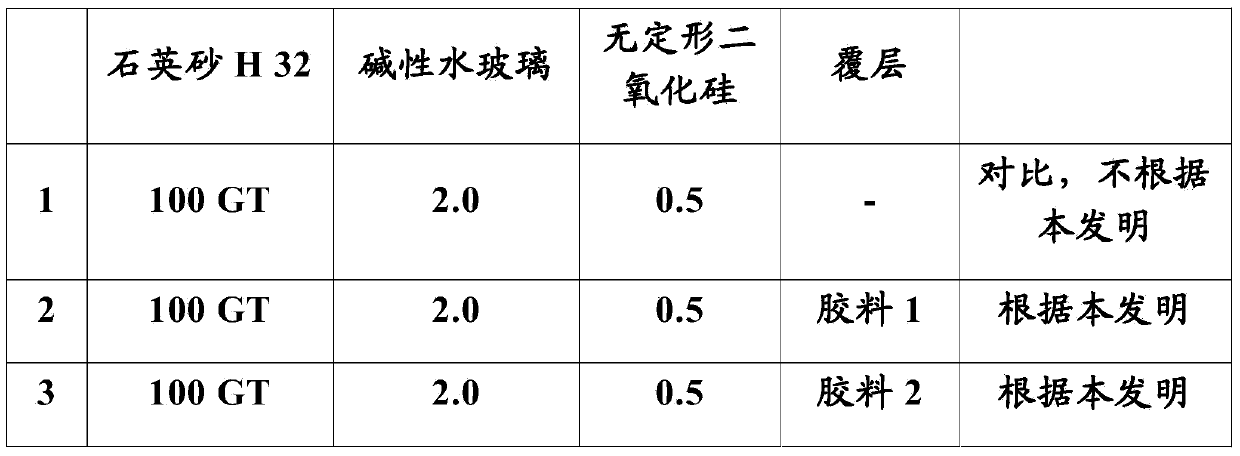

[0066] In this example, the effect of salt in the size on the strength of the sized core was examined. The core compounds 1 to 3 used had the compositions indicated in Tables 1 to 3 .

[0067] Table 1: Composition of rubber compounds

[0068]

[0069]

[0070] Die-casting compounds were produced by supplying water and crushing the clay therein for at least 15 minutes followed by applying a high-shear mixer. The refractory components, pigments and dyes are then stirred in for at least 15 minutes until a homogeneous mixture is produced. Two additives, methyl formate or ethyl formate, were added to sizes 1 and 2 together with the described refractories. Additives such as wetting agents, defoamers and preservatives as well as adhesives are finally stirred in.

[0071] For the tests described below, the size was adjusted to a viscosity suitable for the application in the range of 0.6 Pas. The adjustment takes place by adding a corresponding amount of water to the original...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com