Toothed wheels and transmission

A technology of gears and gear pairs, which is applied in the directions of gear transmission, gear lubrication/cooling, belt/chain/gear, etc. It can solve the problems of oil not being used, small operating area, narrow friction coefficient, etc., to improve transmission efficiency, Effect of reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

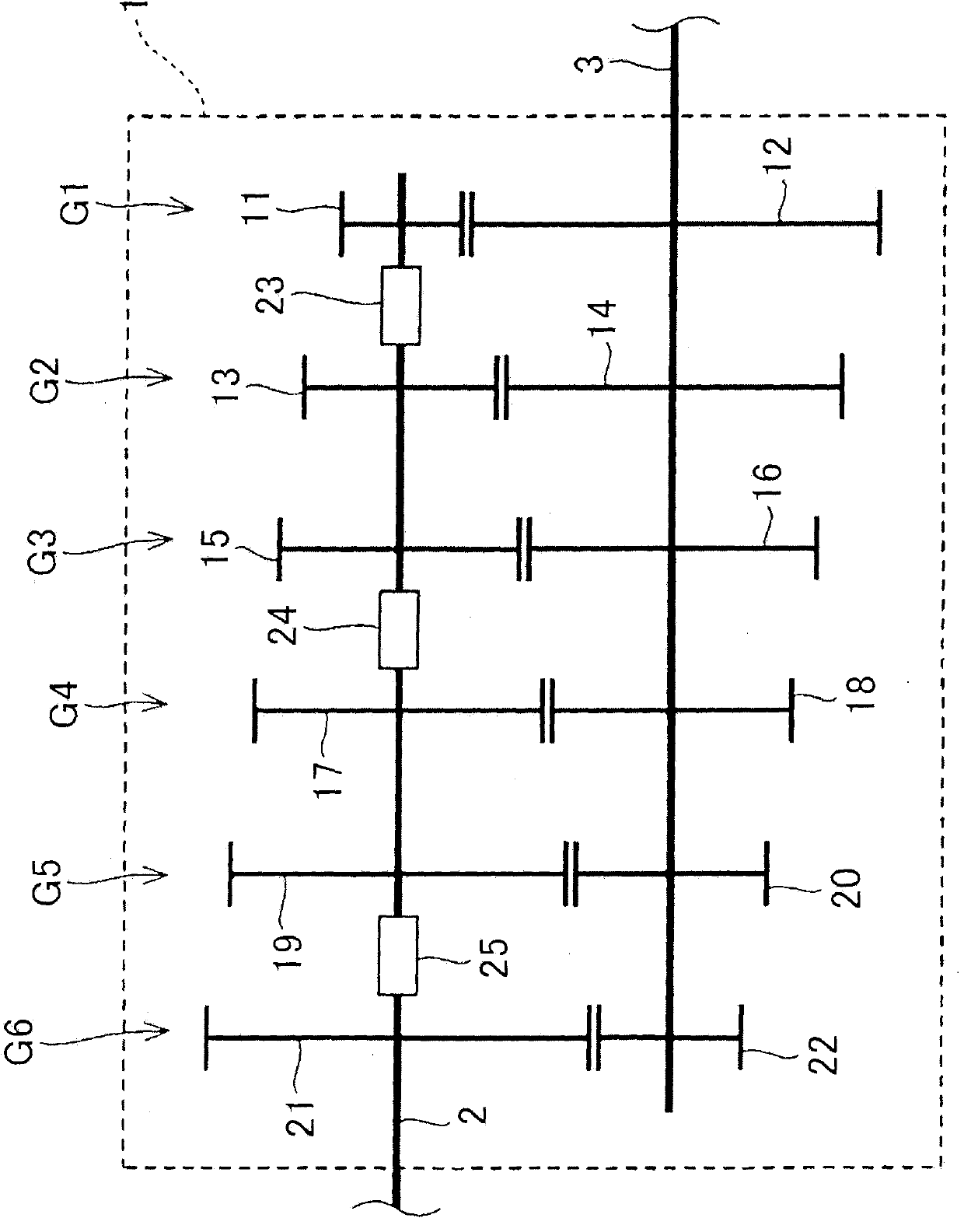

[0026] figure 1 A transmission in which a gear according to an embodiment of the present invention is incorporated is schematically shown. The transmission 1 is a well-known device installed on a vehicle to change the rotational speed of a traveling power source such as an internal combustion engine and transmit the rotation to transmission wheels. The transmission 1 has six forward speeds.

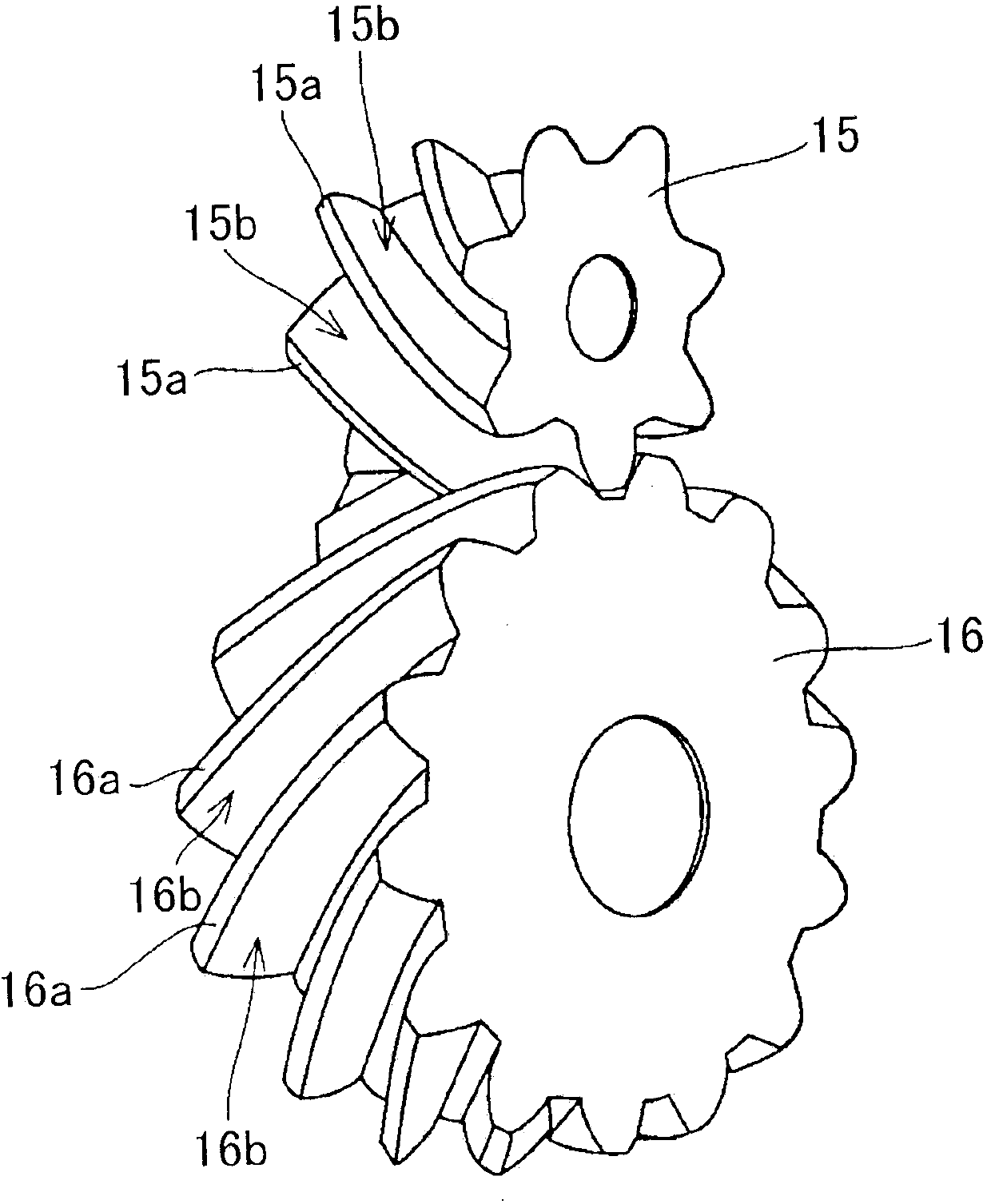

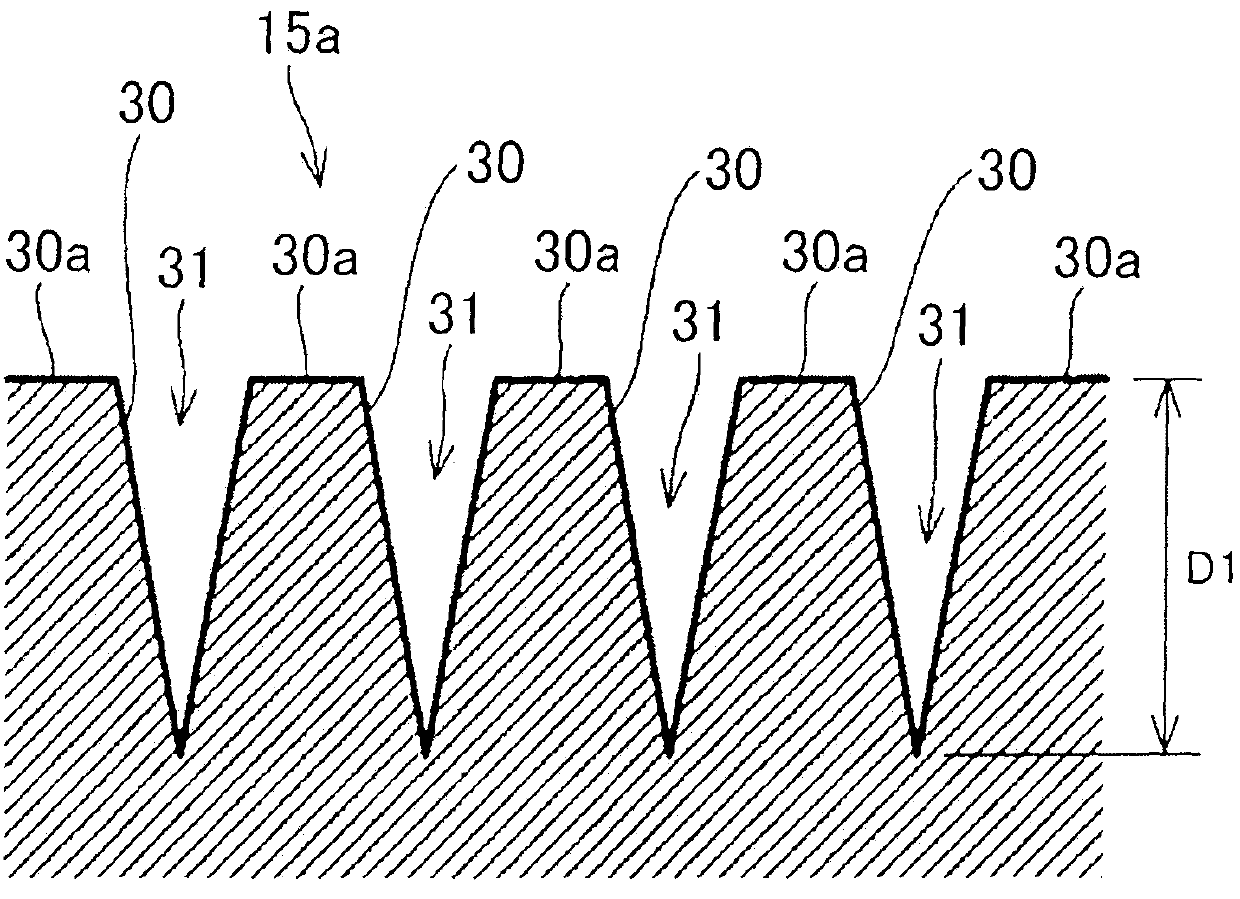

[0027]The transmission 1 is equipped with an input shaft 2 and an output shaft 3 . The input shaft 2 and the output shaft 3 are arranged parallel to each other. The first to sixth gear pairs G1 to G6 are arranged between the input shaft 2 and the output shaft 3 . The first gear pair G1 is composed of a first drive gear 11 and a first driven gear 12 meshing with each other. The second gear pair G2 is composed of a second drive gear 13 and a second driven gear 14 meshing with each other. The third gear pair G3 is composed of a third drive gear 15 and a third driven gear 16 meshing with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com