Back crushing device

A crushing device and section technology, applied in the direction of crop processors, cutters, agricultural machinery and implements, etc., to achieve the effect of improving the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

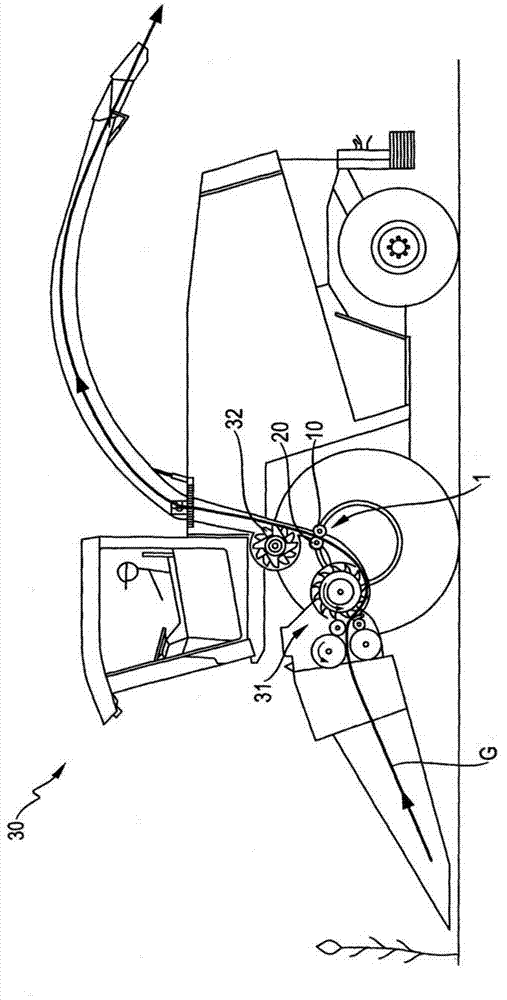

[0033] figure 1 An agricultural harvester in the form of a self-propelled field grinder 30 is shown in a schematic side view. The field shredder 30 is equipped in a manner known per se (and therefore not shown in detail) with front and rear wheels and a (in addition) main drive motor driving them, in order to be moved over a field for harvesting vegetation. The plant population is received into the machine by means of an additional harvesting attachment on the front side, so that it is subsequently in the form of a flow of harvest G (through the through-through, arrow-provided line passing through the field grinder 1 to be briefly shown) are conveyed by different conveying and / or processing units through the machine 1 and processed there, in particular crushed. Here, the rotating pull-in rollers arranged in pairs carry out the pre-compression of the crop G, so that when the crop G passes through the downstream grinding unit 31, it is formed between a rotating grinding drum w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com