Forced circulation system and forced-circulation brake system constructed therefrom

A circulation system and circulation pump technology, applied in the direction of brakes, brake components, brake transmission devices, etc., can solve problems such as brake failure, air resistance that cannot be completely eliminated by force, and full-effect braking that cannot be guaranteed all the time. Brake safety, eliminate brake weakness, prevent brake failure and fire effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

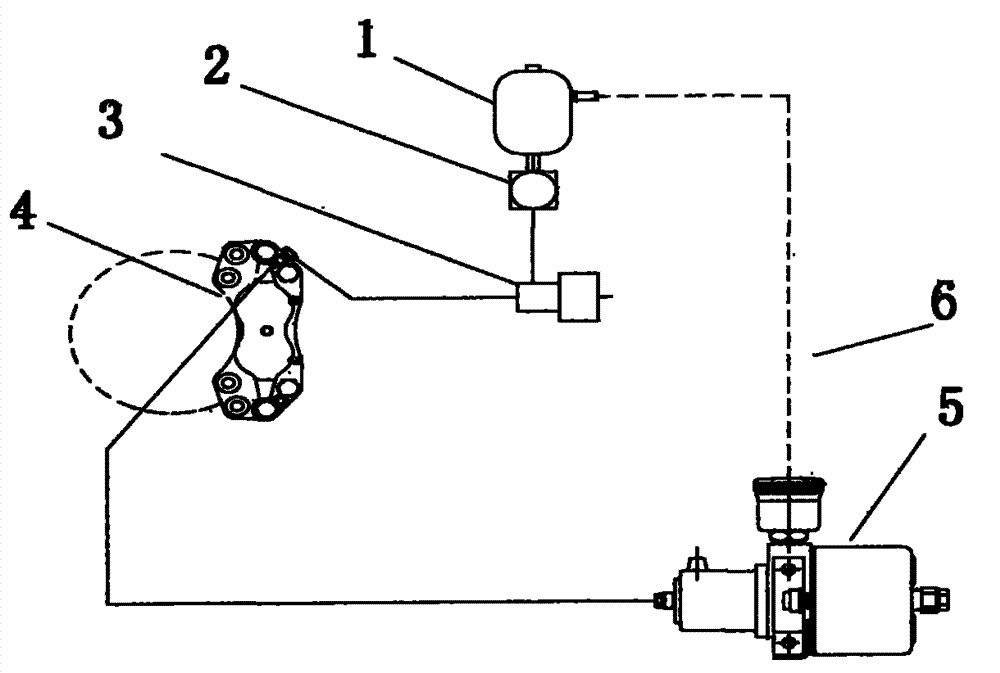

[0076] see image 3 , similar to Embodiment 1 of the forced circulation system of the present invention, the only difference is that the figure 2 The on-off valve 3 in is replaced by a one-way valve 301. Other tags and figure 2 correspond to the same.

Embodiment 3

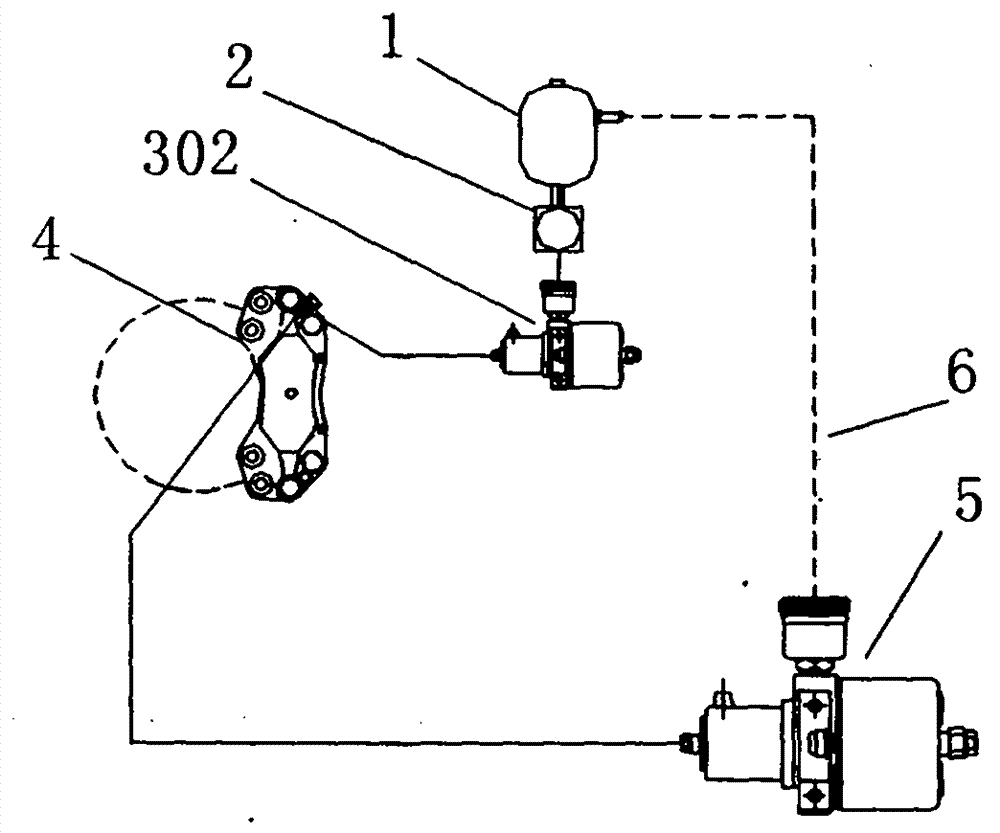

[0078] see Figure 4 , similar to Embodiment 1 of the forced circulation system of the present invention, the only difference is that the figure 2 The one-way valve 301 in is replaced by booster pump 302. Other tags and figure 2 correspond to the same.

[0079] Embodiment 1 of the forced circulation braking system of the present invention

[0080] This embodiment corresponds to the first technical solution of the forced circulation braking system of the present invention.

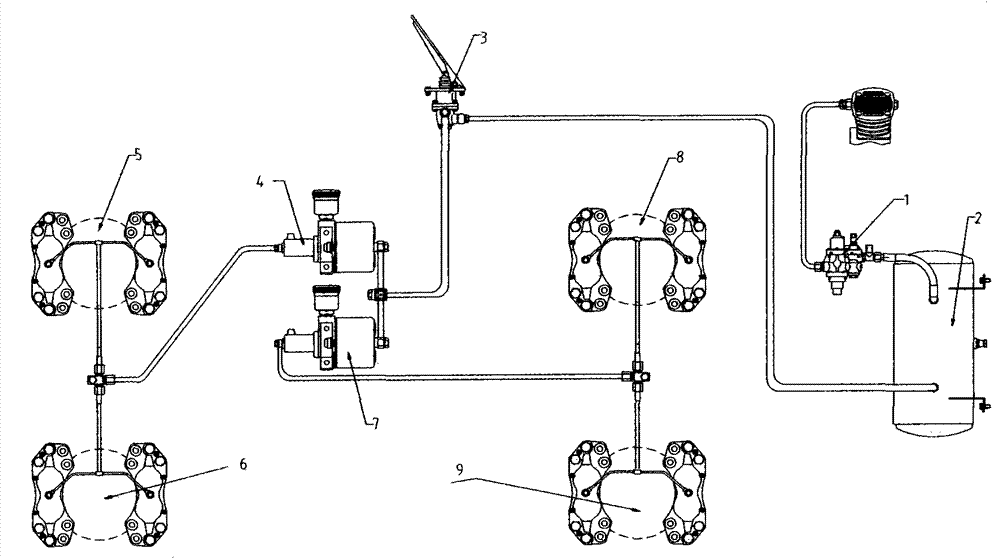

[0081] see Figure 5 , a forced circulation brake system, including a pressure regulating valve 21, a single-chamber air reservoir 20, a single-chamber air brake master valve 22, a front axle forced circulation system and a rear axle forced circulation system;

[0082] The front axle forced circulation system includes fuel tank 1, circulation pump 2, switch valve 3 (that is, switch control part), brake caliper group 4, afterburner pump 5, oil return pipe 6 (pipe marked with dotted line) and oil pipe....

Embodiment 7

[0105] This implementation corresponds to the third technical solution of the braking system of the forced circulation system in the present invention.

[0106] see Figure 8 , the forced circulation brake system described in this embodiment includes a pressure regulating valve 301, a double-chamber air storage tank 303, a double-chamber air brake master valve 312, a front axle forced circulation system and a rear axle forced circulation system;

[0107] The inlet of the pressure regulating valve 301 is connected to an external pressure gas source, the outlet of the pressure regulating valve 301 is connected to the inlet of the double-chamber air storage tank 303, and one outlet of the double-chamber air storage tank 303 is connected to one chamber of the double-chamber air brake master valve 312 through the air pipeline The air inlet, the other outlet of the double-chamber air storage tank 303 is connected to the air inlet of the other chamber of the double-chamber air brake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com