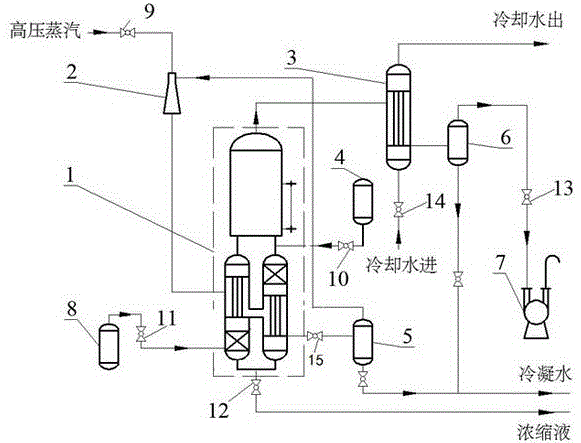

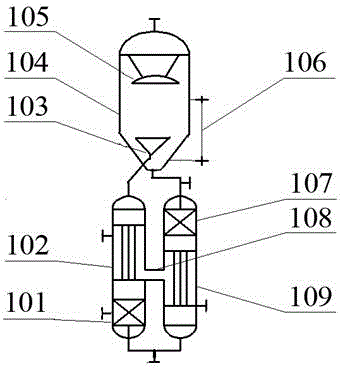

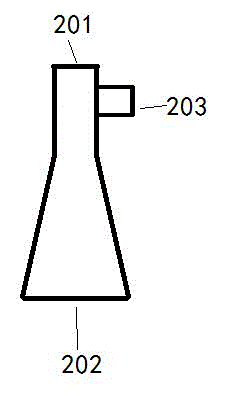

A liquid-gas linkage forced circulation heat pump low-temperature evaporation concentration crystallization device

A technology of forced circulation and low temperature evaporation, which is applied in the direction of solution crystallization, evaporation, evaporator accessories, etc., to achieve the effects of reducing energy consumption, reducing equipment volume, and enhancing heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Taking the 28% D-p-hydroxyphenylglycine evaporation concentration and crystallization system of a certain pharmaceutical factory as an example, the specific requirements are: the single batch processing capacity is 350Kg, the evaporation temperature of the liquid medicine is less than 40 degrees, the evaporation residence time is less than 1 hour, and the final concentration Greater than 67%, that is, the distilled water strength is greater than 200Kg / h. The specific embodiment of the present invention and technology, equipment parameter are as follows (different mother liquor initial conditions are different, and heat transfer coefficient, heat transfer area are slightly different):

[0058] 1) First turn on the Roots vacuum pump (7), then turn on the vacuum valve (13), and the system is pre-vacuumized.

[0059] 2) After the vacuum degree reaches -0.095, slightly open the feed valve (10), so that the raw material enters the evaporator (1) from the raw material tank (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com