Axle counter installation test detector

A detection device, axle counting equipment technology, applied in the direction of measuring devices, optical devices, vehicle route interaction equipment, etc., can solve the problem of affecting the entire process and working time of equipment detection and debugging, installation and test inspection can not be carried out at the same time, installation Inaccurate standards and other issues, to achieve the effect of small error, simple structure, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

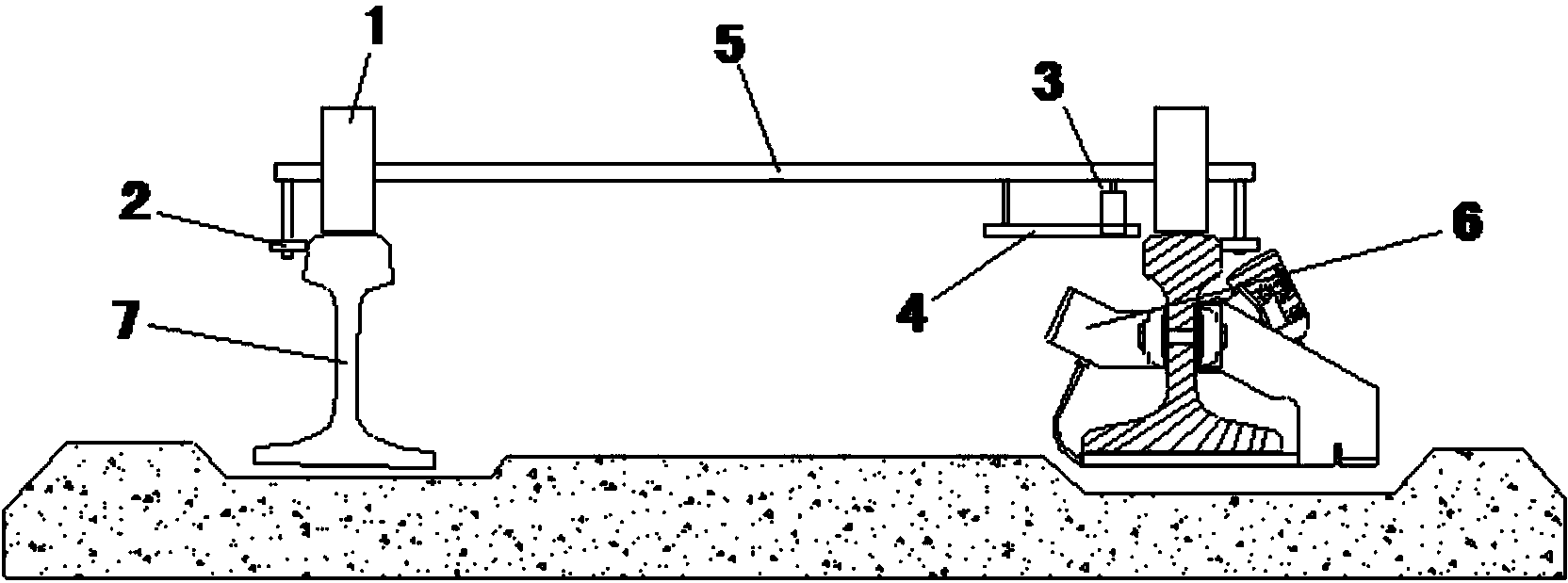

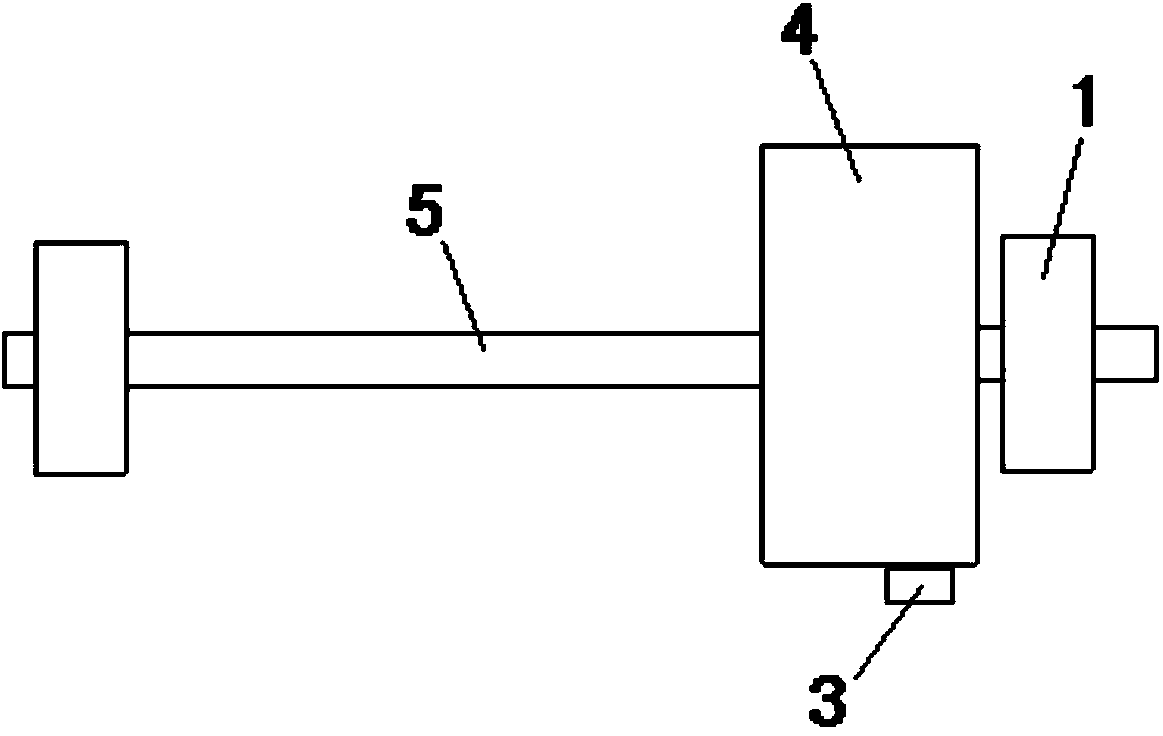

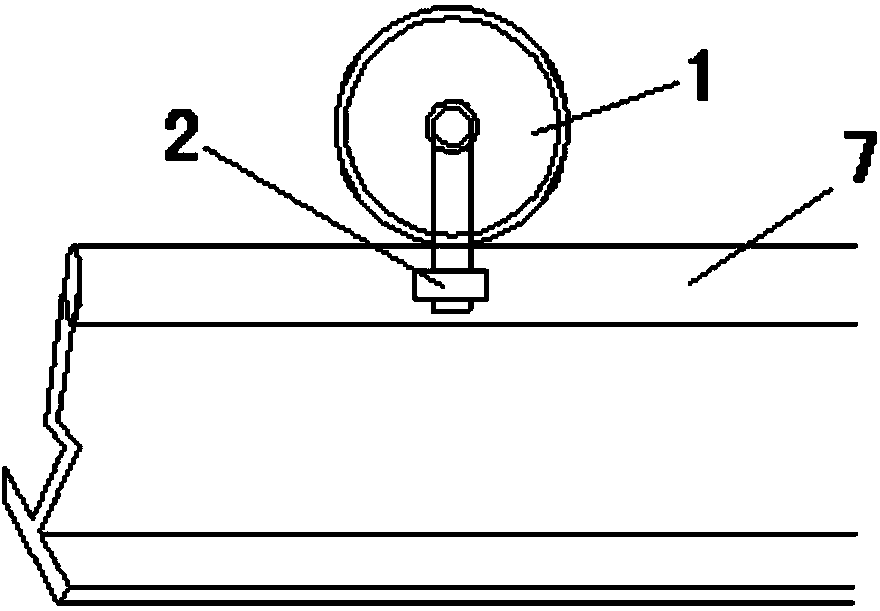

[0018] like Figure 1-Figure 4 shown. Axle counting equipment installation test detection device, including a running wheel smooth connection shaft 5 horizontally placed above a pair of rails 7 to be tested, a pair of running wheels 1 are installed on the running wheel stable connection shaft 5, and the two running wheels 1 are respectively placed to be tested On the top surface of the rail 7, the two ends of the running wheel stable connection shaft 5 are respectively vertically downwardly connected with a positioning shaft. Attached to the side surface of the rail 7 to be tested, the bottom of the running wheel stable connection shaft 5 is connected to a simulated wheel pair test board 4, and the front end of the simulated wheel pair test board 4 is equipped with an infrared height measuring device that cooperates with the axle counting magnetic head sensor 6 on the rail 7 to be tested Instrument 3.

[0019] The lower surface of the simulated wheel pair test board 4 is at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com