Driving plate for driving steel wire rope pulley to rotate

A wheel-driven and wire-rope technology, applied in the field of wire-rope-driven rotary dials, can solve problems such as lack of a good solution, and achieve the effects of improving loading and unloading efficiency, reducing work intensity, and preventing rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

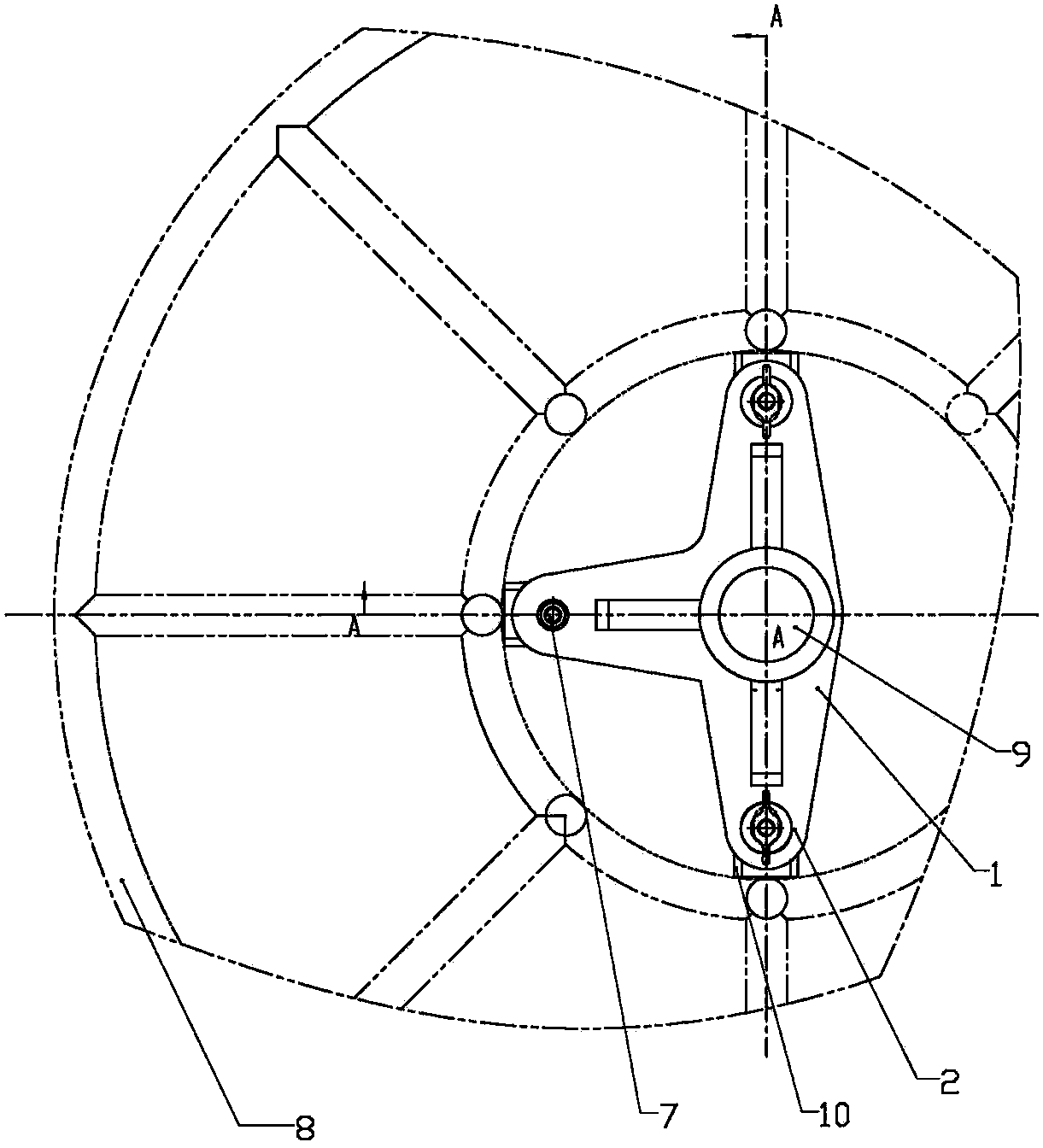

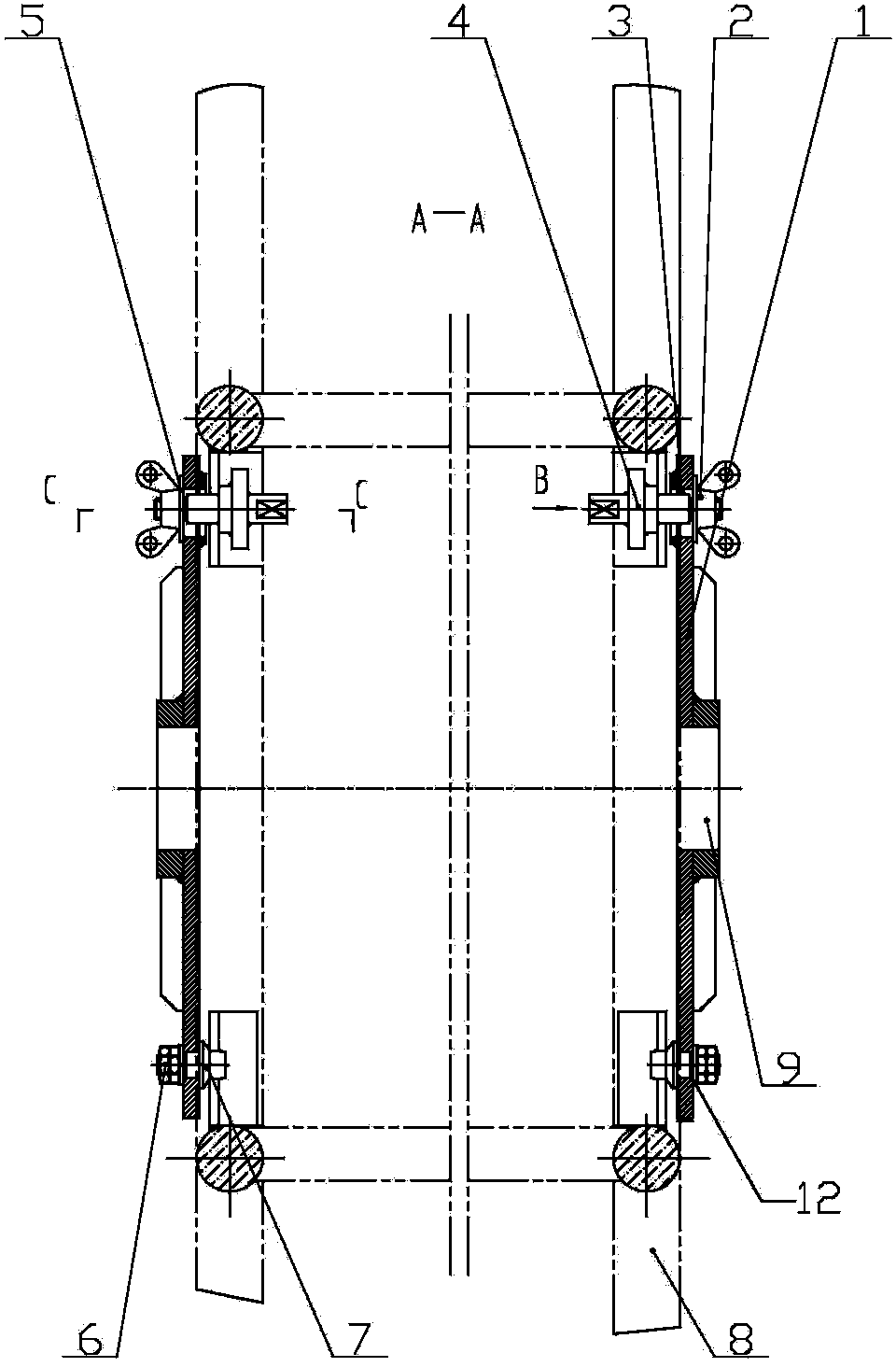

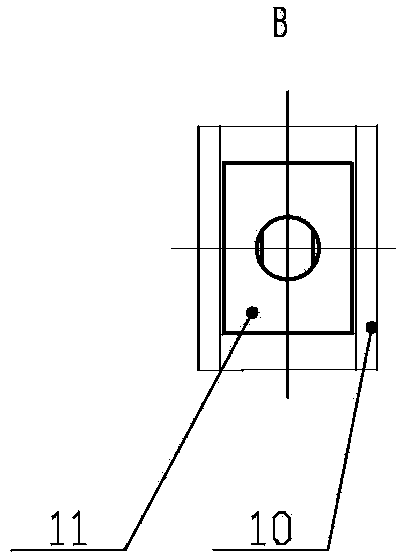

[0015] Refer to the attached figure 1 to attach Figure 4 The rotary dial driven by a wire sheave of the present invention will be described in detail below.

[0016] A wire sheave-driven rotary dial of the present invention, its structure includes a pair of "T" shaped dials 1, each of the dials 1 is fixedly connected to the sheave 8 through a channel steel 10, each of the The dial 1 is respectively provided with a circular positioning hole 12 and two oblong grooves 3, the two oblong grooves 3 are respectively located at the ends of the two arms of the dial 1 at 180 degrees, and the positioning hole 12 is located at the same The end of the support arm with a long circular groove of 90°, the channel steel 10 is arranged in the inner circular hole of the sheave 8 and is fixed with the sheave 8, and the channel steel 10 and the dial 1 pass through respectively The fixed bayonet 7 is connected with the movable bayonet 4, and one end of the fixed bayonet 7 is fastened on the dial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com