Handmade polyurea, its preparation method and use

A polyurea, manual technology, applied in the field of polyurea, can solve the problems of long gel time, prolong gel time, and mechanical properties can not be guaranteed at the same time, achieve the effect of no VOC emission, reduce use cost, and prolong the operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

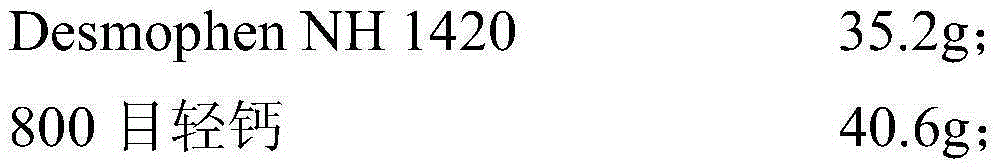

[0047] This embodiment discloses an artificial polyurea, including the following components by weight ratio:

[0048] A component:

[0049] Toluene diisocyanate 41.9g;

[0050] DesmophenNH142022.4g;

[0051] Polyether polyol PPG-100080.7g;

[0052] Propyl carbonate PC5g;

[0053] B component:

[0054]

[0055]

[0056] The preparation steps of the artificial polyurea are as follows:

[0057] Preparation of component A: add 22.4g of DesmophenNH1420 and 80.7g of PPG-1000 into the container, stir the liquid at low speed for 5 minutes, heat it to 110~120℃, turn on the vacuum pump, and the vacuum degree is -0.1~-0.08 MPa, vacuum dehydration for 2 hours to remove a small amount of water contained in the raw materials, the detected moisture content is below three ten thousandths, and the liquid material temperature is cooled to about 25°C. Add 41.9g of toluene diisocyanate into the container, stir and react at room temperature for 1 hour. After the exotherm of the reaction is over, slowly incre...

Embodiment 2

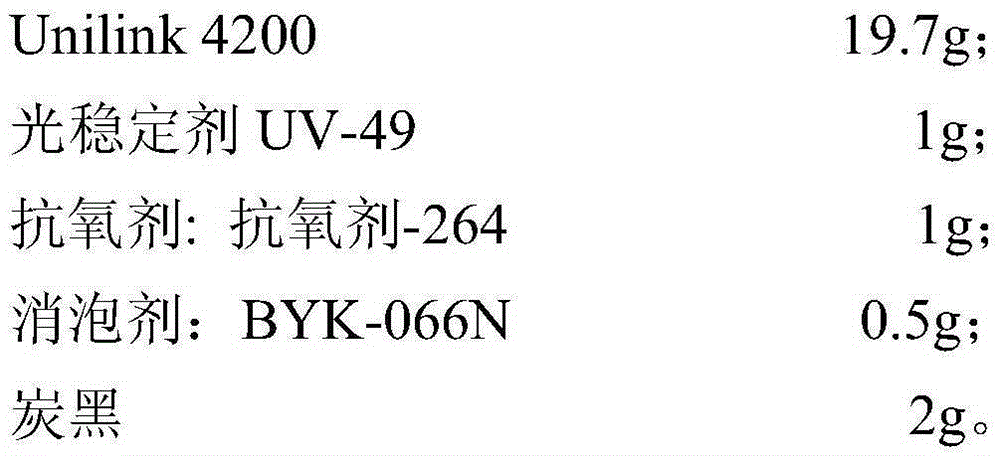

[0066] This embodiment discloses an artificial polyurea, including the following components by weight ratio:

[0067] A component:

[0068] Diphenylmethane diisocyanate 62.6g;

[0069] Polyether polyol PPG-200071.4g;

[0070] Unilink420011g;

[0071] Propyl carbonate PC5g;

[0072] B component:

[0073]

[0074] The preparation steps of the artificial polyurea are as follows:

[0075] Preparation of component A: add 11g of Unilink4200 and 71.4g of PPG-2000 into the container, stir the liquid at low speed for 5 minutes, then heat to 110~120℃, turn on the vacuum pump, the vacuum degree is -0.1~-0.08MPa , Vacuum dehydration for 2 hours to remove a small amount of water contained in the raw materials, the detected moisture content is below three ten thousandths, and the liquid material temperature is cooled to about 25 ℃. Add 62.6g of diphenylmethane diisocyanate to the container, stir and react at room temperature for 1 hour. After the exotherm of the reaction, slowly increase the temperatu...

Embodiment 3

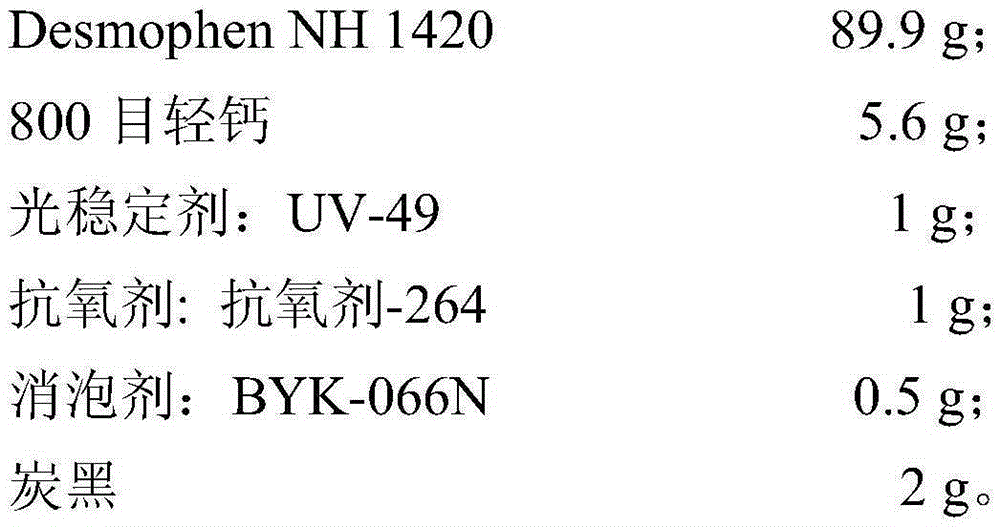

[0083] This embodiment discloses an artificial polyurea, including the following components by weight ratio:

[0084] A component:

[0085] Toluene diisocyanate 54.1g;

[0086] DesmophenNH152057.8g;

[0087] Polytetrahydrofuran polyol PTMG-100033.1g;

[0088] Propyl carbonate PC5g;

[0089] B component:

[0090]

[0091] The preparation steps of the artificial polyurea are as follows:

[0092] Preparation of component A: add 57.8g of DesmophenNH1520 and 33.1g of PTMG-1000 into the container, stir the liquid at low speed for 5 minutes, then heat to 110~120℃, turn on the vacuum pump, and the vacuum degree is -0.1~-0.08 MPa, vacuum dehydration for 2 hours to remove a small amount of water contained in the raw materials, the detected moisture content is below three ten thousandths, and the liquid material temperature is cooled to about 25°C. Add 54.1g of toluene diisocyanate into the container, stir and react at room temperature for 1 hour. After the exotherm of the reaction is over, slowly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com