Alkylation reactor and method

An alkylation reactor and an alkylation reaction technology, which are used in the production of liquid hydrocarbon mixtures and the petroleum industry, etc., can solve the problems of low reaction temperature and a large amount of gasification space, and can increase the contact area and increase the contact time. , The effect of reaction low temperature control effect is good

Active Publication Date: 2014-06-18

CHINA PETROCHEMICAL CORP +1

View PDF14 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The reaction heat removal method of the patented reactor is the gasification of light hydrocarbons. In order to maintain a low reaction temperature, the reactor needs a large amount of gasification space

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0028] Further illustrate the present invention below in conjunction with accompanying drawing.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

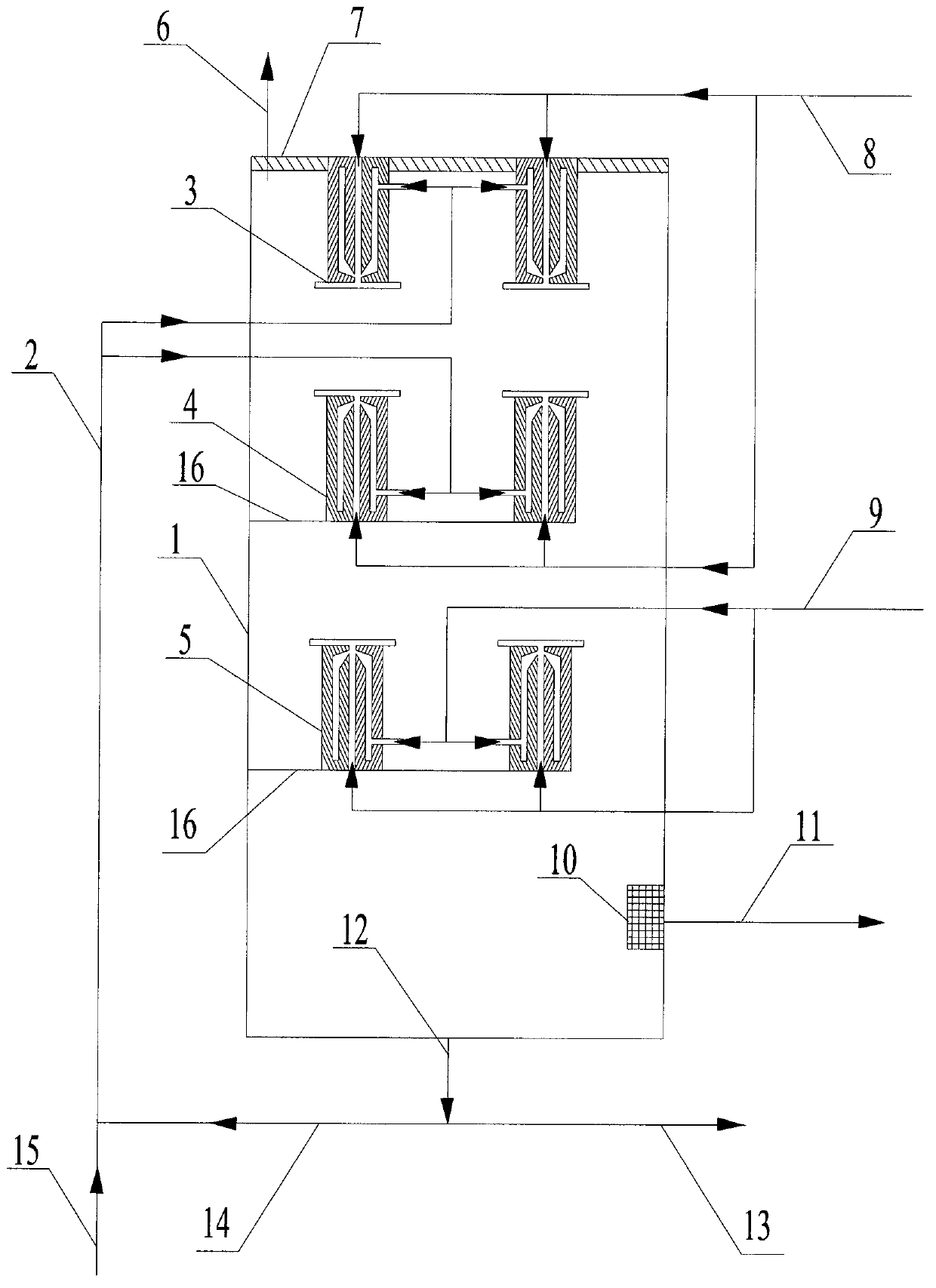

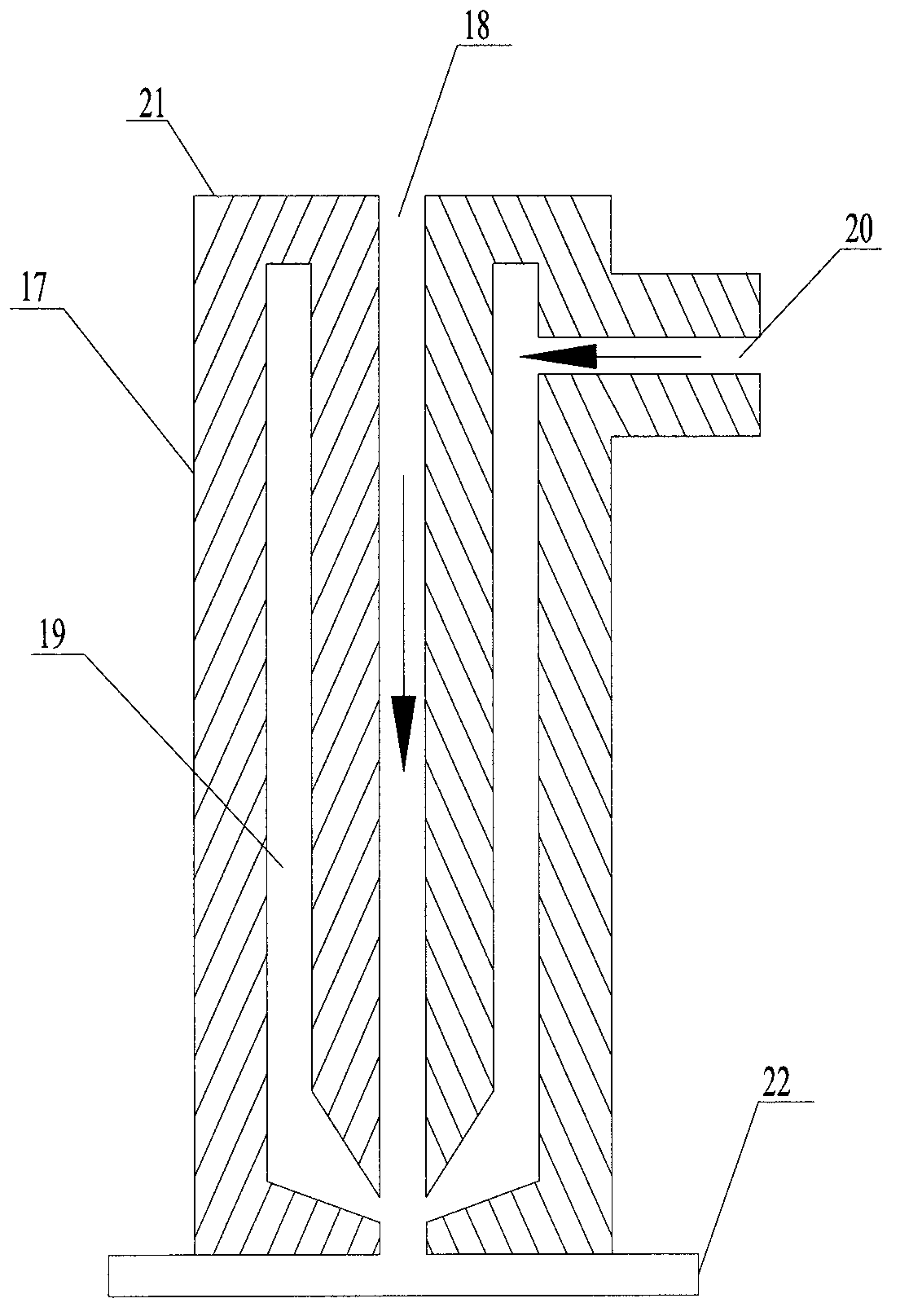

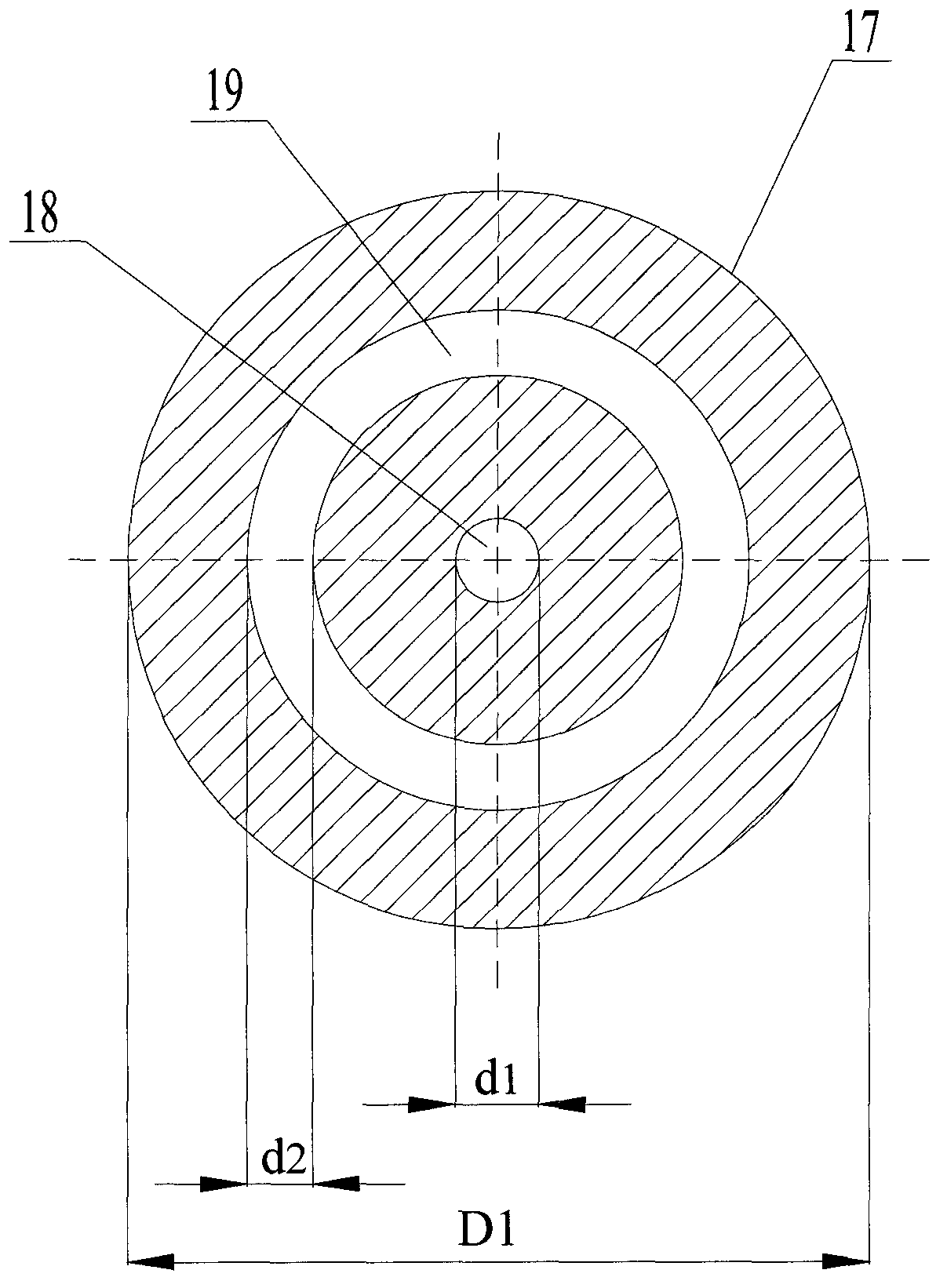

The invention discloses an alkylation reactor. The interior of the reactor is mainly composed of multiple groups of nozzles and distributors at the tail ends of the nozzles, and a reaction material is sprayed by the multiple groups of nozzles, mixed and subjected to a reaction. The alkylation reactor is characterized in that the multiple groups of nozzles are arranged inside the reactor from top to bottom; the first group of nozzles is connected with the top of the reactor, and the spraying direction is downward along the reactor. Other groups of nozzles are fixed inside the reactor by fixed brackets. The number of nozzles in each group is usually 1-4. Each nozzle comprises two channels, the first channel of the nozzle penetrates through the center of the nozzle, and the second channel is annular in shape and is separated from the first channel. The two channels are converged at the bottom of each nozzle and are communicated with each distributor. The alkylation reactor has the characteristics of simple structure, short process flow, large elasticity of operation and the like, and is suitable for a reaction for generating high-octane-rating alkylate oil from isoalkane and low-carbon olefin under an action of a liquid acid catalyst.

Description

technical field [0001] The invention belongs to the field of petrochemical industry, in particular to an alkylation reactor and an alkylation reaction method. Background technique [0002] High-octane alkylate produced from low-carbon olefins and iso-alkanes under liquid acid catalysis is an ideal gasoline blending component. The low-carbon olefins and isoalkanes used in the alkylation reaction have poor solubility with liquid acid catalysts, especially isoalkanes and liquid acid catalysts are difficult to dissolve. Although the solubility of low-carbon olefins and acid catalysts is slightly better than that of isoalkanes, low-carbon olefins are easily polymerized into high polymers above C12 under the action of liquid acid catalysis above 10°C. In addition, the alkylation reaction is still an exothermic reaction. If the reaction temperature is not properly controlled, the side reactions of light olefin polymerization will be aggravated, which will seriously affect the qual...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10G50/00

Inventor 左世伟焦云李网章郝代军刘金龙岳建伟高有飞郭巧玲赵敏洁李宏伟孙大力

Owner CHINA PETROCHEMICAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com