Self-power-generation biomass gasification furnace

A biomass and gasifier technology, applied in the field of gasifiers, can solve problems such as excessive smoke, tar blockage, and insufficient utilization of biomass, and achieve the effect of solving blocked pipelines and eliminating smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

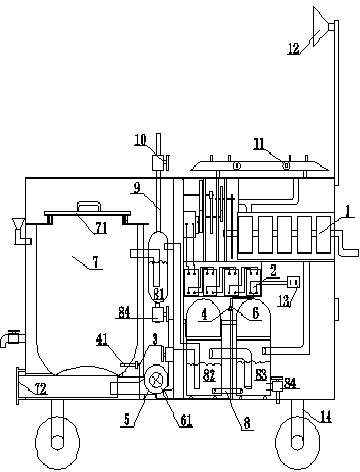

[0009] like figure 1 As shown, the self-generating biomass gasification furnace includes a power generation device 1, a power storage device 2, an ignition device 3, a fan device 5, a furnace body 7, a tar filter device 8, and a pure exhaust device 9, wherein the power generation device 1 Connected to the power storage device 2, the power generation device 1 adopts a hand-operated DC generator, which is composed of a power storage spring and a gear box. When in use, it is only necessary to hand-operate the generator handle for 2 minutes to store electricity. The device 2 includes a filter and a capacitor bank for storing electric energy; the circuit connection end of the ignition device 3 is connected with the power storage device 2, and the ignition switch 4 is connected in the circuit to control whether to ignite, and the igniter 41 at the ignition end of the ignition device 3 is inserted into the furnace. Body 7 bottom ignition holes; body of furnace 7 is connected with tar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com