Lifting form concrete chimney construction method

A construction method and chimney technology, which are applied in the field of chimney construction technology, can solve the problems of high hydraulic system conditions, expensive equipment, and chimney safety and quality problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

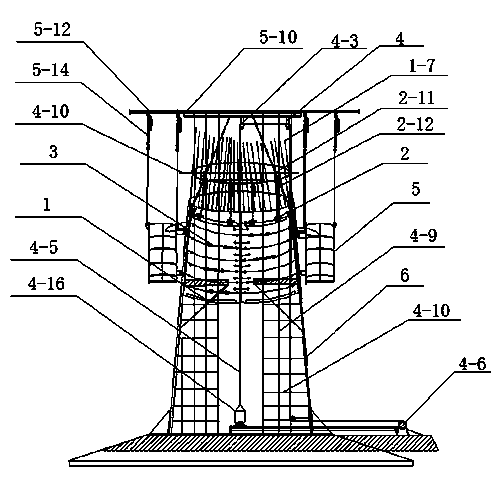

[0042] Referring to the accompanying drawings, a construction method for lifting and touching a concrete chimney, its specific technical scheme is:

[0043] 1. The installation of the lifting formwork system, the lifting formwork is installed on the outer wall of the chimney:

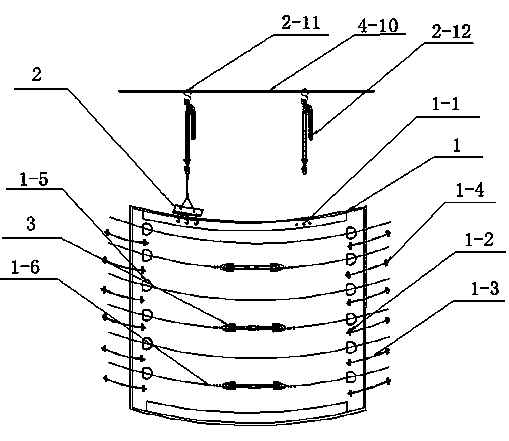

[0044] 1.1. Install the lifting formwork 1, which will be divided into four lifting formworks 1 in the shape of a "︶" arc, which will form a circle from the bottom above the chimney foundation to form a combination of lifting formwork 1, and the vertical edges between the lifting formwork 1 Overlap each other, the lifting template 1 is installed outside the chimney reinforcement 1-7, and the hanging hole 1-1 of the lifting template 1 faces upward;

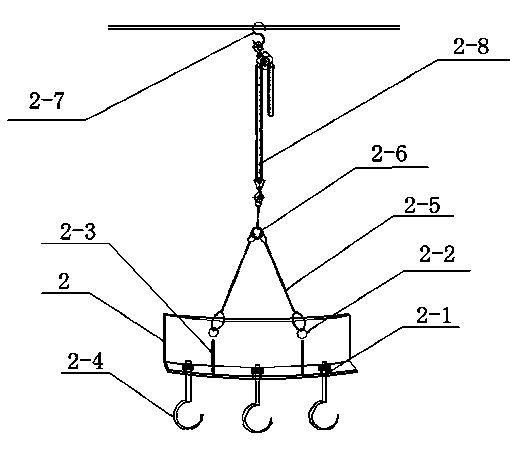

[0045] 1.2. Install the pendant 2, hang the swivel hook 2-4 on the pendant 2 on the pendant hole 1-1 of the lifting template 1, the swivel hook 2-4 remains rotatable within the swivel hole 2-1, and the pendant 2 The inclined rib plate 2-3 is facing the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com