Binding wire supply device of electric power optical cable erecting machine

A technology for bundling and supplying wires, which is applied in the direction of optical fiber/cable installation, optics, light guide, etc. It can solve the problem that there is no tension in the bundling wire or the tension cannot be adjusted, which affects the quality and safety of optical cable construction, and it is difficult to ensure that the set parts do not fall off, etc. problems, to achieve the effect of avoiding falling accidents of machine parts from high altitudes, improving the level of safe construction, and simple loading and binding lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

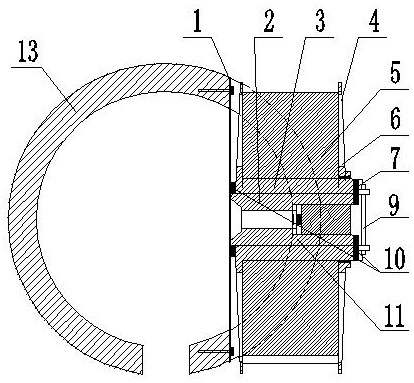

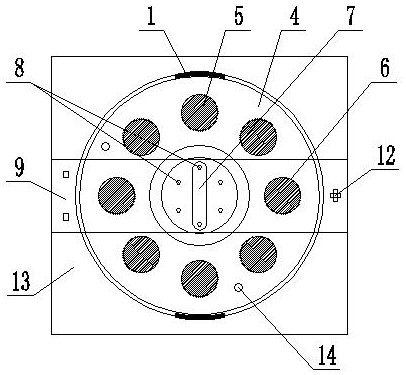

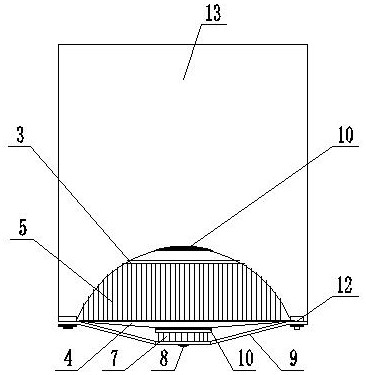

[0026] The implementation of the binding wire supply device of the power optical cable erecting machine will be further described in detail below in conjunction with the accompanying drawings (see Figure 1-18 ):

[0027] The bundled wire supply device of the power optical cable erecting machine consists of a base mounting plate 1, a base shaft 2, a wire supply disk body 3, a wire supply disk cover 4, a binding wire 5, a weight reduction hole 6, a pressure blocking cover 7, and male and female clamping positions. 8. A safety stopper 9, a damper 10, a base shaft threaded hole 11, a movable fixing device 12, and a rotating cylinder 13 are formed; the pressure blocking cover 7 is integrally made with a screw, and the diameter of the screw of the pressure blocking cover 7 is smaller than that of the base The diameter of the shaft threaded hole 11; the base mounting plate 1, one end of the safety stopper 9, and the movable fixing device 12 are installed on the rotating cylinder 13....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com