A magnetorheological fluid self-generating transmission device driven by shape memory alloy

A technology of memory alloy and magnetorheological fluid, which is applied in the direction of clutches, fluid clutches, mechanical equipment, etc., can solve the problem of less research on the joint application of shape memory alloy and magnetorheological fluid in the adaptive adjustment of magnetorheological fluid transmission devices , to achieve the effect of self-adaptive adjustment, compact structure and reliable transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

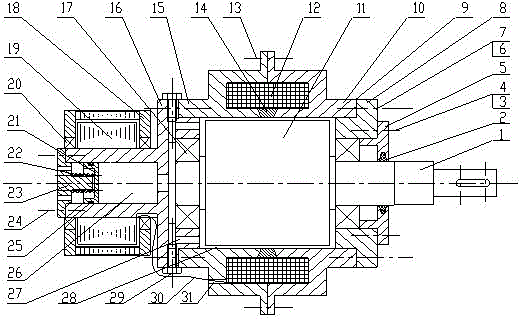

Embodiment 1

[0021] see figure 1 , a magneto-rheological fluid self-generating transmission device driven by a shape memory alloy, including a driving part, a driven part, an excitation coil 12 and a DC generator, wherein the driving part includes a driving shaft 1 and a driving inner cylinder 11, and the driving The shaft 1 is connected with the power device, and the driving shaft 1 can rotate under the drive of the power device. In this embodiment, the right end of the driving shaft 1 has a keyway, and the driving shaft 1 and the power device are connected by a key; the driving inner cylinder 11 is sleeved on the drive shaft 1 and can rotate synchronously with the drive shaft 1. Of course, the active inner cylinder 11 and the drive shaft 1 can also be integrally structured.

[0022]The driven part includes a driven shell, a left end cover 16 and a right end cover 8, the driven shell is sleeved outside the active inner cylinder 11, the left end cover 16 and the right end cover 8 are fixe...

Embodiment 2

[0026] Compared with Embodiment 1, this embodiment also includes a shape memory alloy driving part, which includes a piston 21, an oil storage chamber end cover 23 and a spring 22 made of shape memory alloy, and the protrusion on the left end cover 16 It is a cylinder structure with an opening, the piston 21 is installed in the protrusion, and an oil storage chamber 26 is formed between the piston 21 and the inner wall of the protrusion, and the oil storage chamber 26 communicates with the working chamber 28; in order to improve the airtightness of the oil storage chamber 26 There is an annular groove on the outer circle of the piston 21, and a sealing ring 25 is embedded in the annular groove, and the sealing ring 25 is used to seal the gap between the piston 21 and the inner wall of the protrusion; the end cover of the oil storage chamber 23 is fixedly connected to the opening end of the protruding part by a fixing screw 24, and the inner side of the end cover 23 of the oil s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com