Braking device of braking air cylinder

A technology of a braking device and a braking cylinder, which is applied to the types of brakes, drum brakes, brake actuators, etc., can solve the problems of not meeting the needs of use, occupying a large space, and complex structure of the braking device, and achieving cost Inexpensive and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

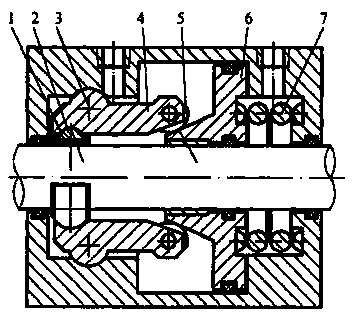

[0008] Such as figure 1 As shown, the braking device of the brake cylinder, the braking device of the brake cylinder, includes a brake shoe 1, a brake shoe seat 2, a rotating shaft 3, a brake arm 4, a pressure wheel 5, a tapered brake piston 6 and Brake spring 7, the brake shoe 1 is installed on the brake shoe seat 2, the brake arm 4 is installed on the rotating shaft 3, the pressure wheel 5 is installed on the bottom of the brake arm 4, and the tapered brake piston 6 is installed on the The movable shoe seat 2 is in contact with the pressure wheel, and the brake spring 7 is installed on the tapered brake piston 6. The braking device of a brake cylinder of the present invention has simple structure and low cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com