Gas stove

A gas stove and gas source technology, which is applied in the combustion method, combustion control, and fuel supply adjustment, etc., can solve the problems of small firepower, insufficient flow curve changes, and insignificant changes in firepower, etc., to increase the effective stroke and convenience. Precisely control the effect of firepower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

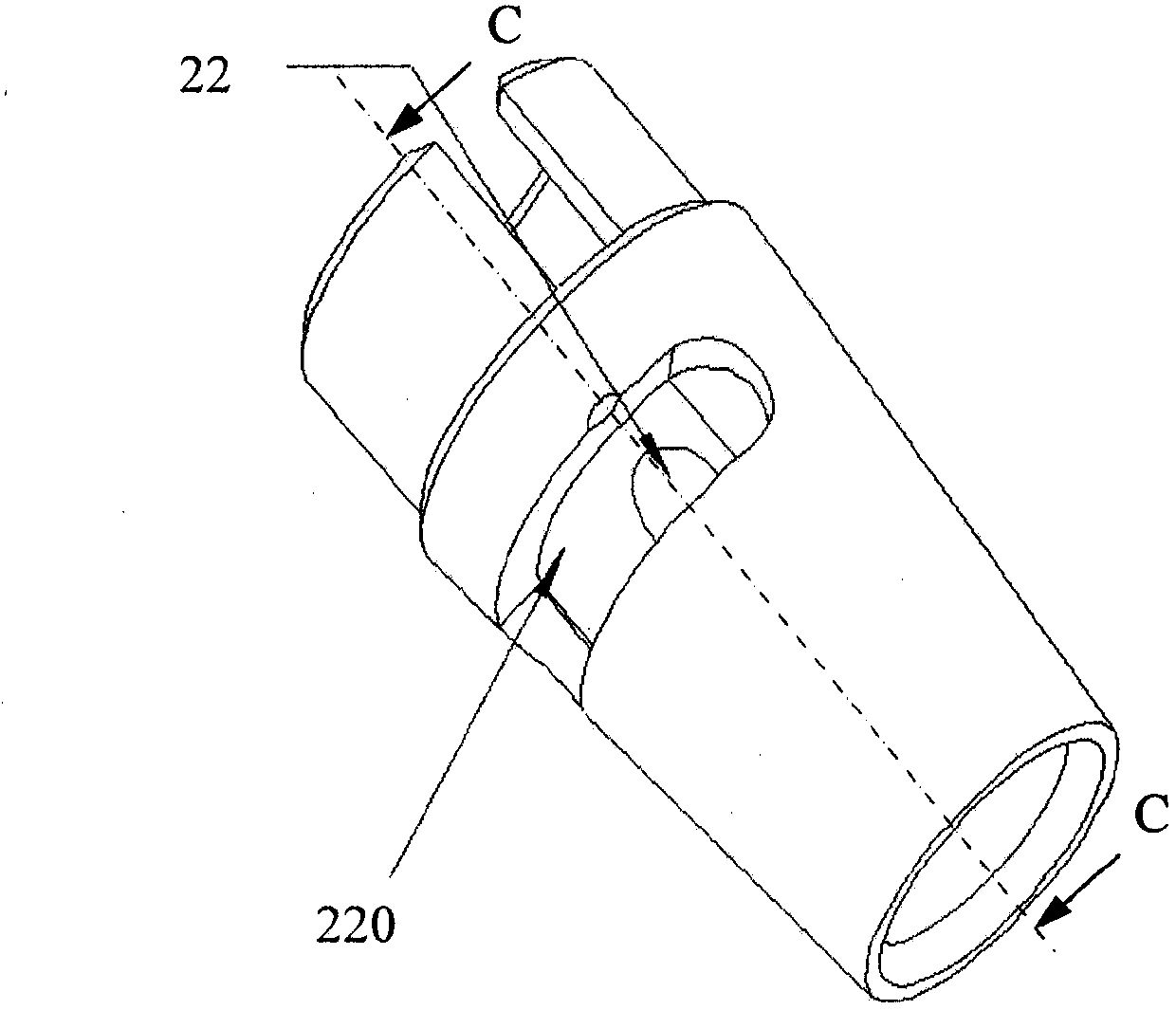

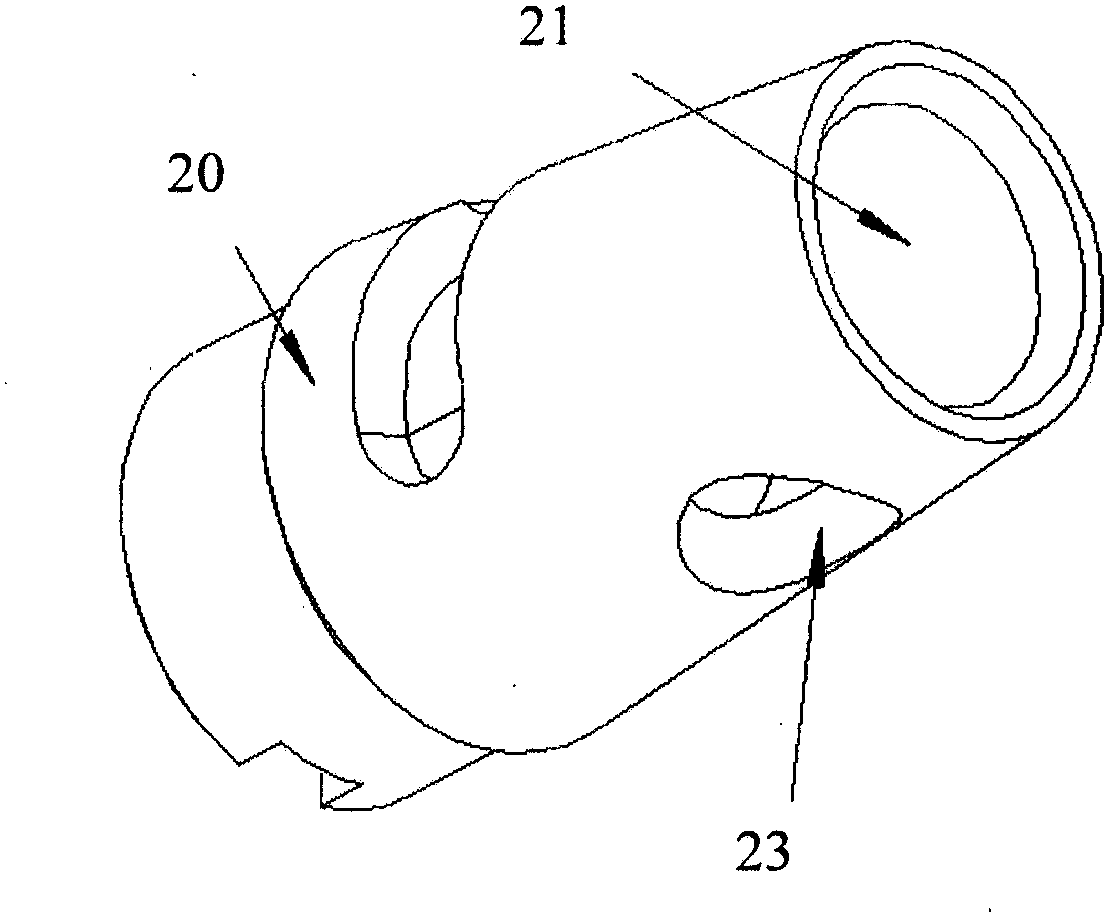

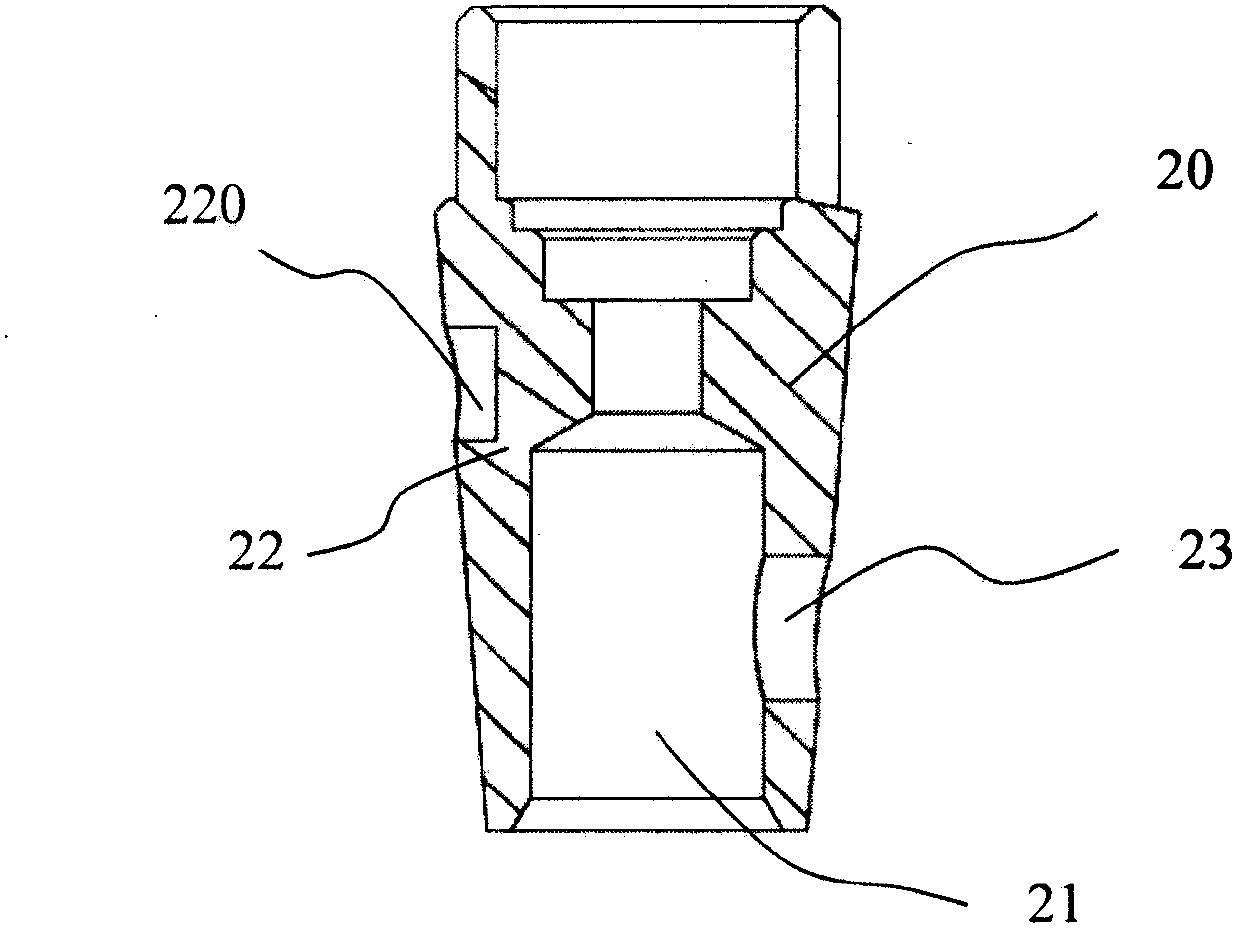

[0032] Please refer to Figure 1 to Figure 19 , The gas stove of the present invention includes an on-off valve 1. The on-off valve 1 includes a valve body 10 and a valve core 20 rotatably arranged in the valve body 1. The valve core 20 is provided with an air inlet passage 21 communicating with an air source. The inner ring fire vent 22 and the outer ring fire vent 23. The valve body 10 is provided with an inner ring main air outlet channel 12 and an inner ring fine adjustment channel 120 corresponding to the inner ring fire air outlet 22, and the valve body 10 is provided with an outer ring main air outlet channel 13 and an outer ring fine adjustment channel 130 corresponding to the outer ring fire air outlet 23. The burner of the gas stove of the present invention in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com