Spherical dynamic seal structure of wobble nozzle of small solid rocket engine

A dynamic sealing structure, solid rocket technology, used in mechanical equipment, pipes/pipe joints/pipes, adjustable connections, etc. Large, difficult to use rubber O-ring seals, etc., to achieve the effect of wide temperature application, light structure and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

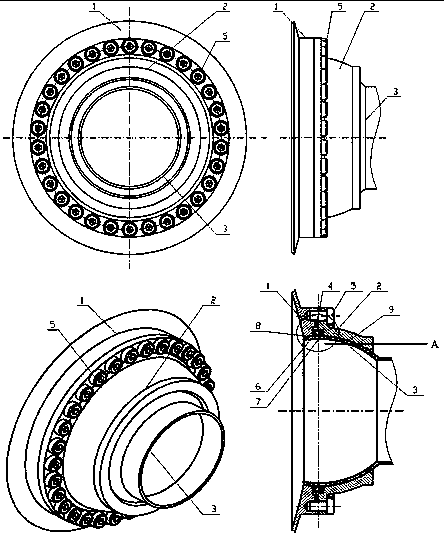

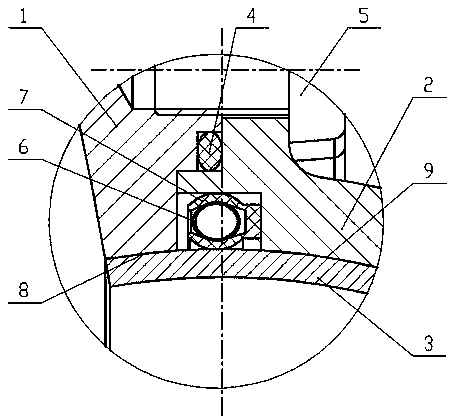

[0013] Such as figure 1 As shown, the spherical dynamic sealing structure of the present invention mainly includes: upstream female sphere 1, downstream female sphere 2, movable male sphere 3, static sealing ring 4, connecting bolt 5, elastic support 6, polytetrafluoroethylene jacket 7 , The upstream sealing spherical surface 8, and the downstream sealing spherical surface 9 are composed. The movable male sphere 3 can swing in the full axial direction around the spherical center of its spherical part during the working process of the nozzle, and the rest of the structure does not move; the upstream female sphere 1 and the downstream female sphere 2 are connected by connecting bolts 5; the upstream female sphere 1 and the The downstream female sphere 2 is realized by the static sealing ring 4; the fixed part composed of the upstream female sphere 1, the downstream female sphere 2, the static sealing ring 4 and the connecting bolt 5 passes through the dynamic part composed of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com