Gas cooker with burner of array polyhedral burner

A firearm and polyhedron technology, applied in the field of gas stoves, can solve the problems of material consumption and lack of competitiveness in material costs, difficulty in adapting to the needs of high-power gas stoves, and low power, and achieve a temperature field that is conducive to combustion and has a significant environmental protection effect , the effect of inhibiting the growth of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

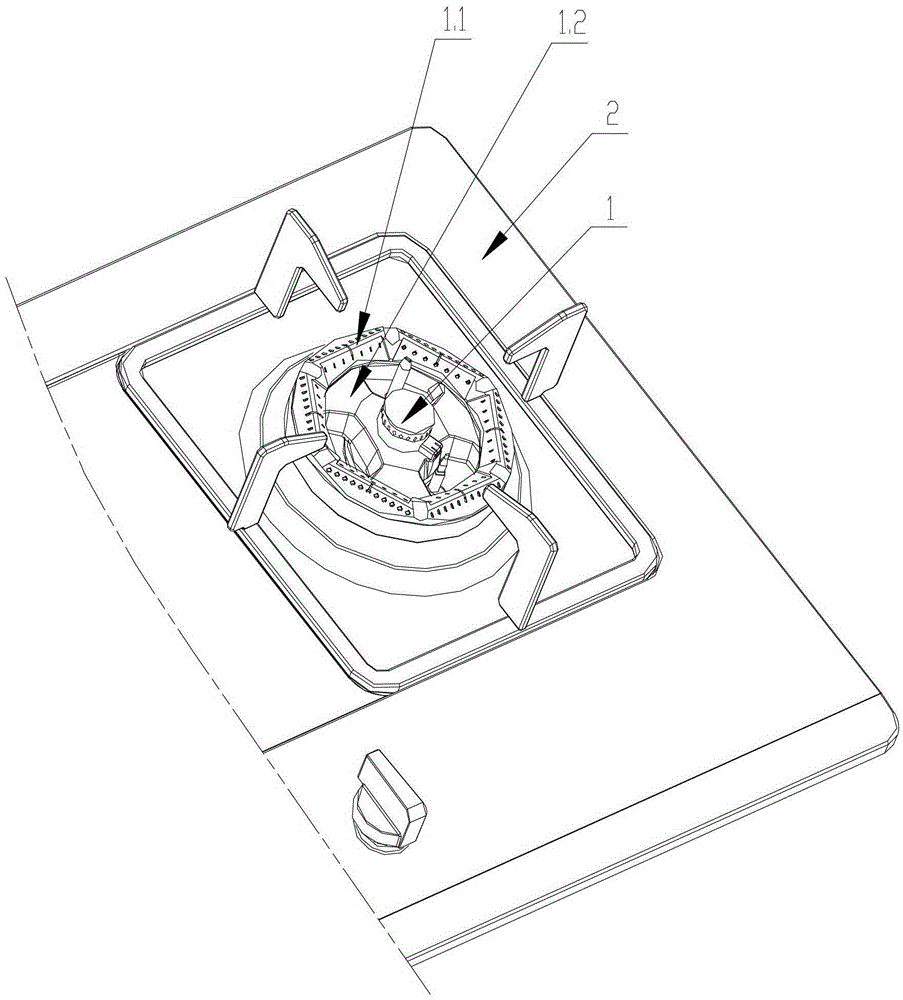

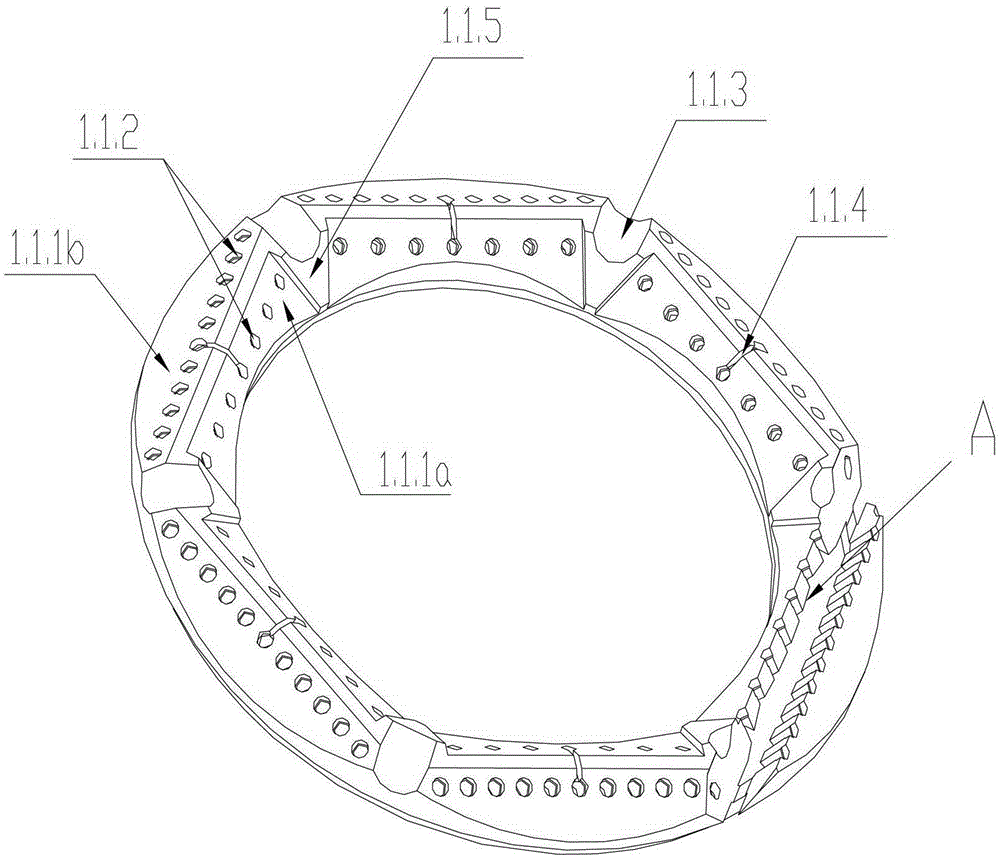

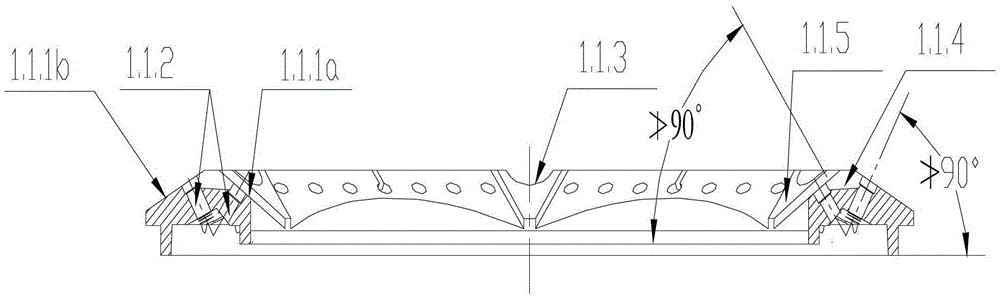

[0034] Such as Figure 1~3 As shown in the gas stove with the burner of the array polyhedron fire distributor, the burner 1 at least includes the array polyhedron fire distributor 1.1 and the burner main body 1.2, and the gas stove at least includes the burner 1 with the array polyhedron fire distributor and the gas stove main body 2; The array polyhedron fire distributor 1.1 is installed on the top of the burner main body, and on the top of the array polyhedron fire distributor, the array polyhedron is formed by 6 inner slopes 1.1.1a and 6 outside slopes 1.1.1b; on each slope forming the array polyhedron, set There is a row of circular fire holes 1.1.2. In the same fire hole, the fire hole fluid passages between the fire holes are parallel to each other, and the airflow direction at the fire hole outlet is consistent; the included angle between the fire hole axis and the horizontal plane is different. If it is greater than 90 degrees, it is preferred to choose within the angl...

Embodiment 2

[0036] Such as Figure 4 As shown, the only difference from Embodiment 1 is that the inner circle of the array polyhedral fire distributor is hexagonal.

Embodiment 3

[0038] Such as Figure 5 , 6 As shown, the only difference from Embodiment 1 is that the inner array surface of the array polyhedron fire distributor is a composite curved surface, and the composite curved surface is composed of inclined surfaces 1.1.1a and 1.1.1c; through-hole airflow is provided between adjacent array surfaces Channel 1.1.3a; direct connection between adjacent outer slopes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com