Blast furnace material level measuring device

A technology of blast furnace charge surface and measuring device, which is applied to measuring device, lubrication indicating device, liquid/fluid solid measurement, etc. It is difficult to control and determine the number of problems, so as to achieve the effect of simple structure, less error factors and accurate falling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

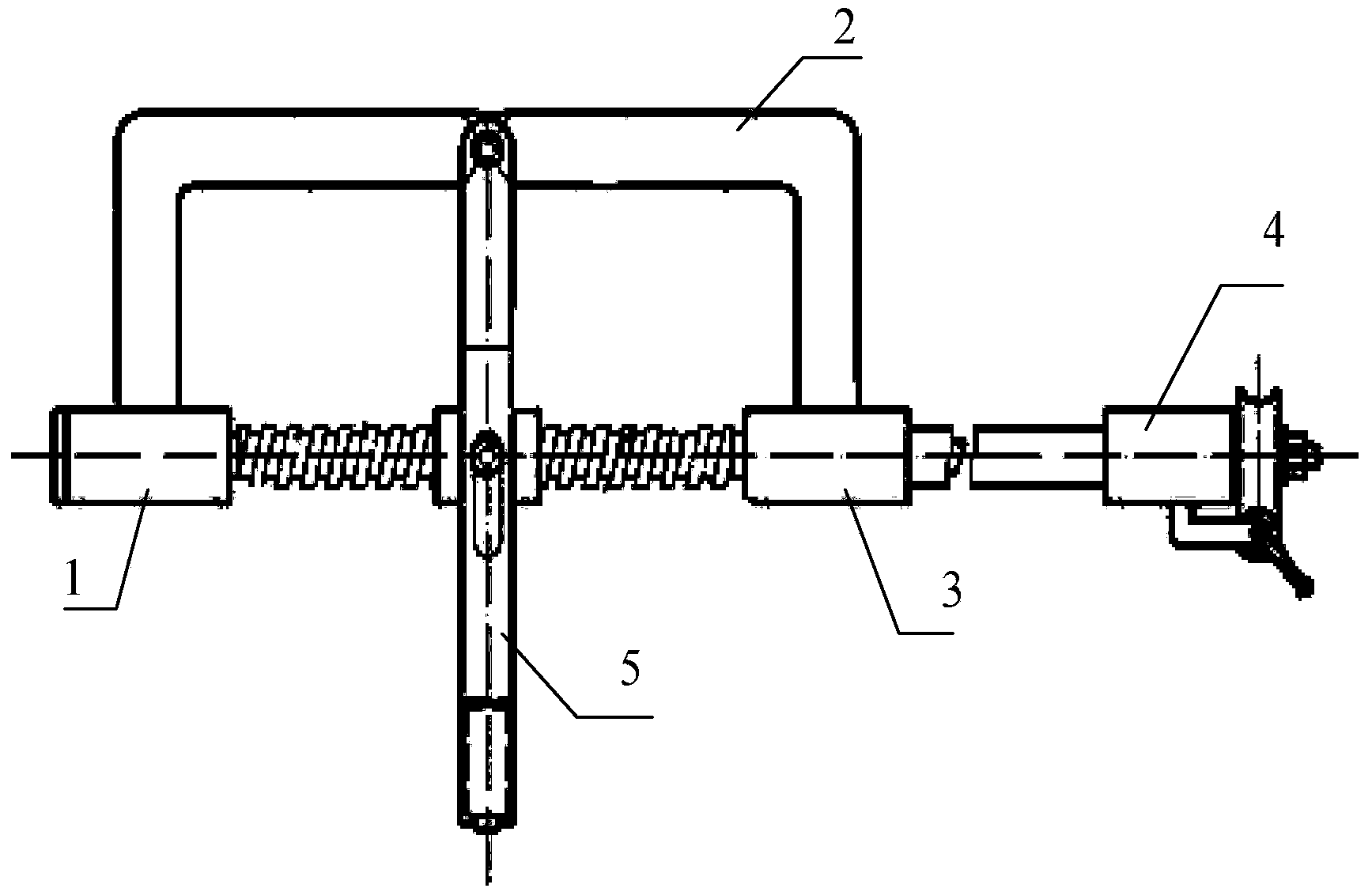

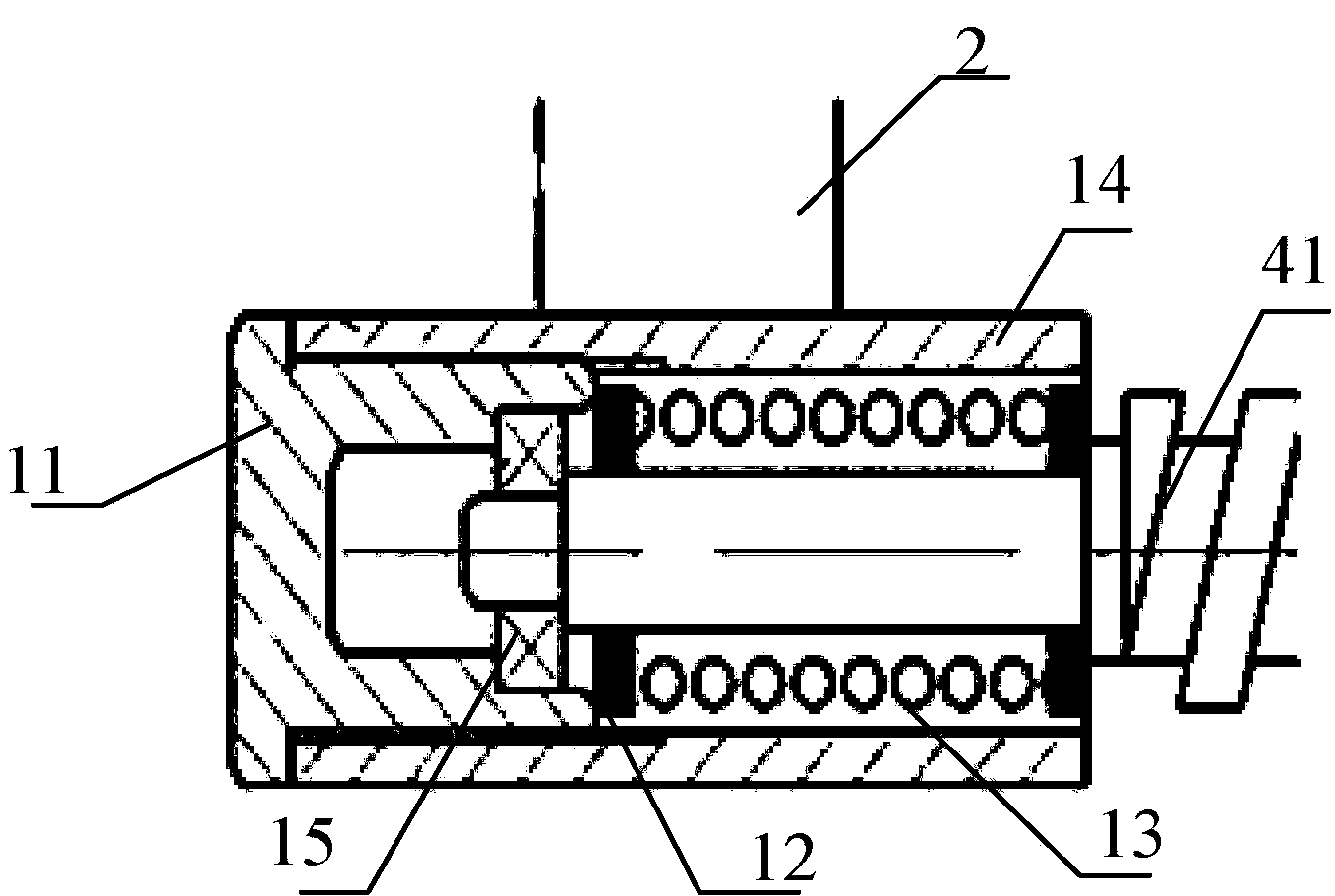

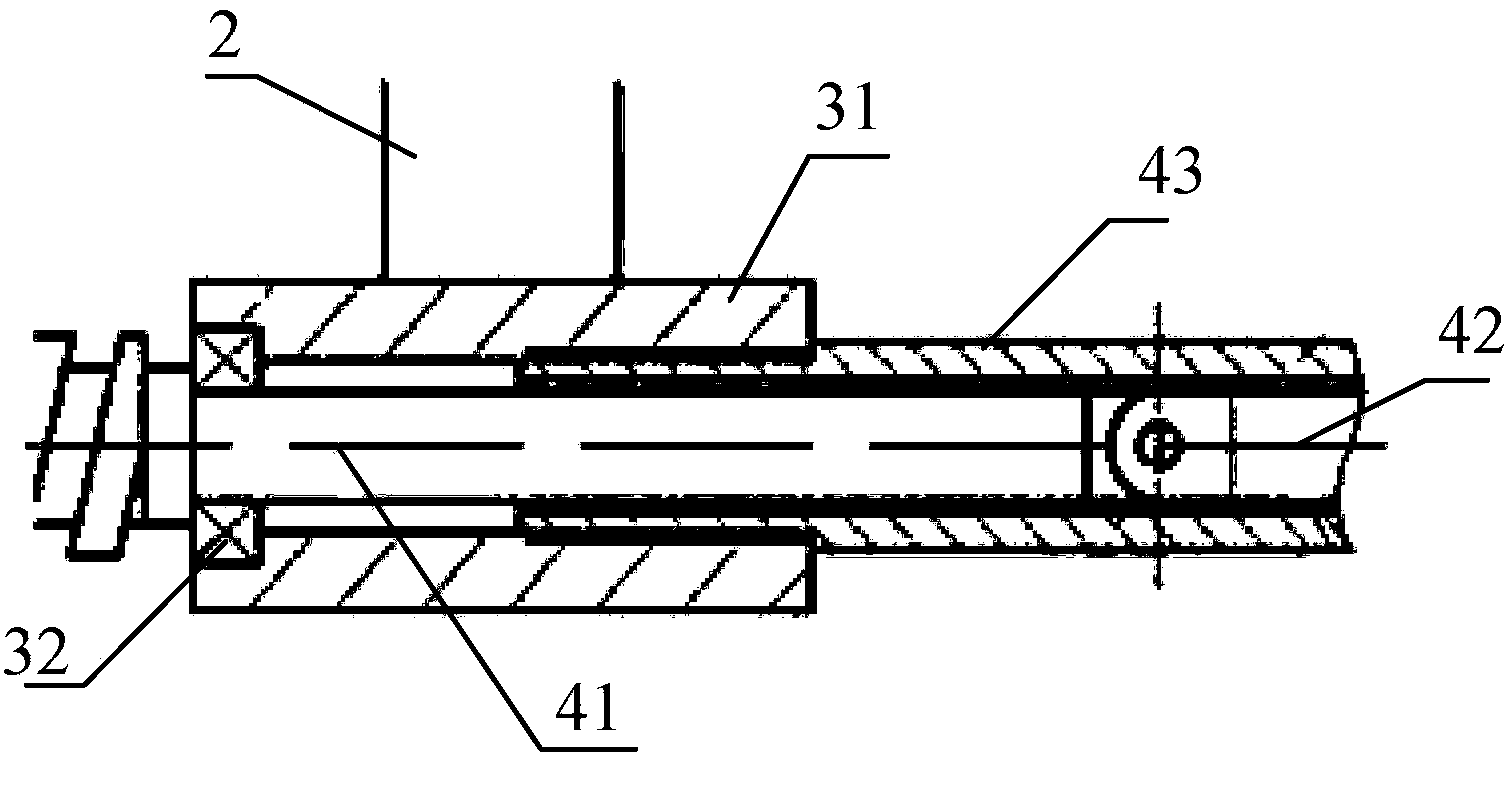

[0016] See Figure 1-Figure 5 , The embodiment of the present invention provides a blast furnace material level measuring device, including: a fastening unit 1, a bracket 2, a fixing unit 3, a measuring unit 5, and a transmission unit 4. See figure 1 , The bracket 2 has an inverted "U" shape or an inverted "V" shape (the embodiment of the present invention adopts an inverted "U" shape). The fastening unit 1 and the fixing unit 3 are arranged on the same straight line; the two ends of the bracket 2 are respectively fixedly connected with the fastening unit 1 and the fixing unit 3 (for example, by welding). The upper end of the measuring unit 5 is movably connected to the bracket 2; the transmission unit 4 passes through the fixed unit 3 and is screwed to the fastening unit 1. The transmission unit 4 is also fixedly connected to the measuring unit 5. The rotation of the transmission unit 4 drives the measurement unit 5 to produce Displacement can be measured at different positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com