High temperature and pressure synchronous application method

A pressure and high temperature technology, applied in the field of simultaneous application of high temperature pressure, can solve the problems of test material damage, uneven pressure distribution, damage, etc., and achieve the effect of uniform force load and small transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

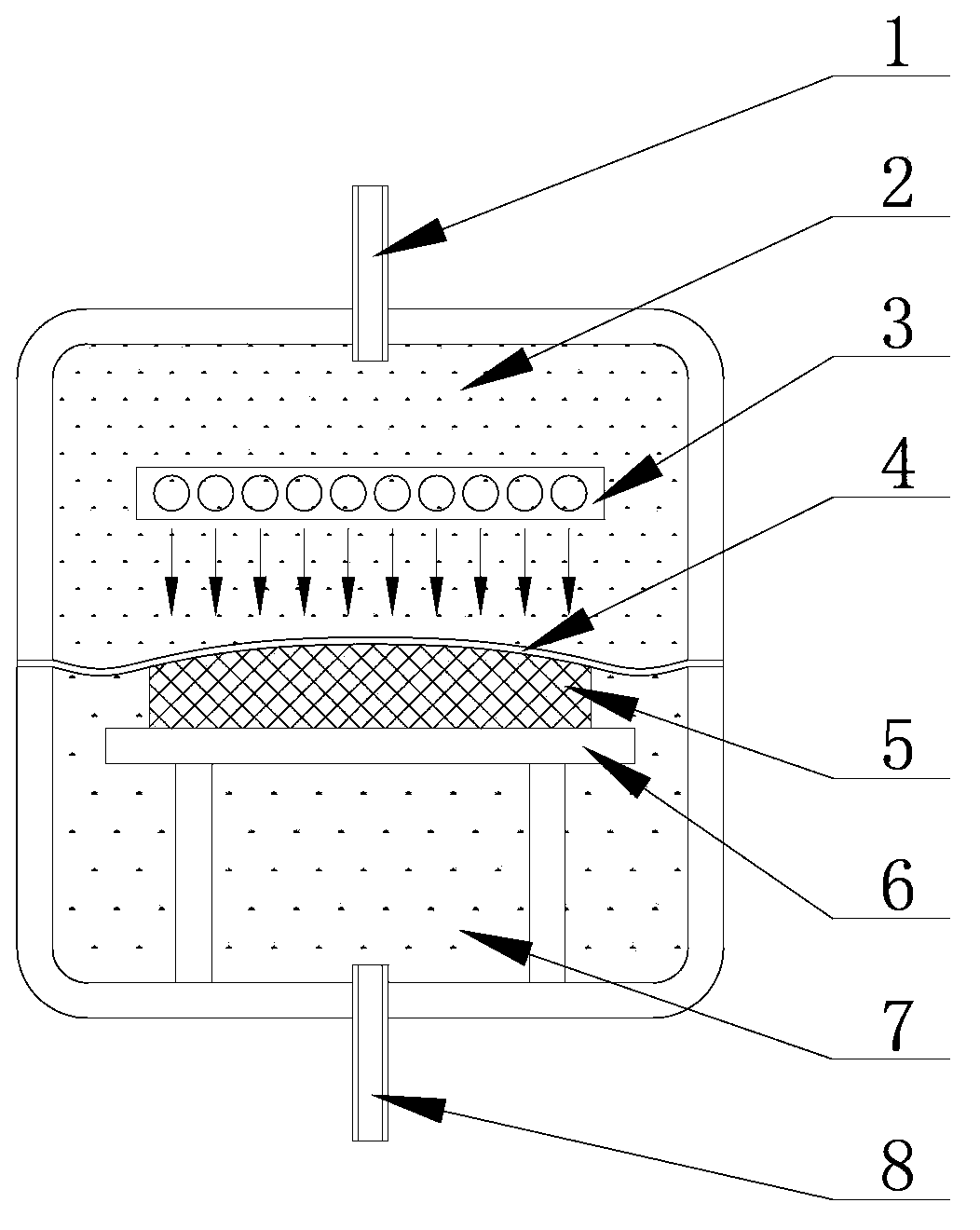

[0025] 1) Prepare a temperature-resistant pressure vessel. There is a movable partition [4] inside the temperature-resistant pressure vessel, which can divide its cavity into two independent parts, cavity one [2] and cavity two [7]. Cavity one [ 2] The inner wall is reserved with the heater mounting seat and air pressure adjustment port [1]; the inner wall of cavity one [2] is reserved with the test piece installation platform mounting seat [6] and air pressure adjustment port [8]; The partition [4] is made of metal foil;

[0026] 2) Prepare the height-adjustable test piece installation platform [6] and heater [3];

[0027] 3) Open the temperature-resistant pressure vessel, take out the movable partition [4]; fix the test piece [5] and the test piece installation platform [6] in the cavity two [7], adjust the installation position of the test piece [5] so that The loaded surface of the test piece [5] protrudes 0mm to 20mm from the installation surface of the movable partition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com