Novel double-Y-waveguide integrated optical device and manufacturing method thereof

A waveguide integration and optical device technology, applied in optical components, optical waveguide light guides, optics, etc., can solve the problems of device volume reduction, low integration, multi-fiber fusion points, etc., to suppress the generation of parasitic waves and improve the device. performance, the effect of reducing parameter drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

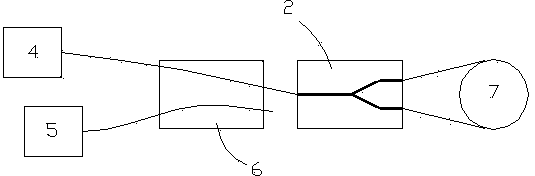

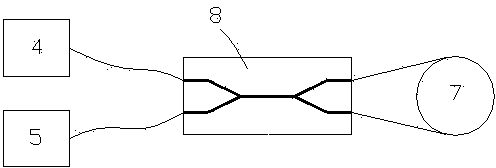

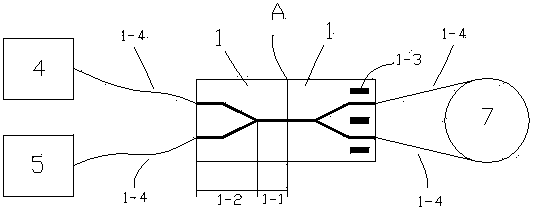

[0021] A novel double Y waveguide integrated optical device, the innovation of which is: the novel double Y waveguide integrated optical device is spliced by two chips 1; the chip 1 is provided with a Y-shaped waveguide; the Y-shaped waveguide is composed of a direct The strip section 1-1 and the bifurcated section 1-2 are composed, and the end surface of the chip 1 that is flush with the outer end surface of the straight section 1-1 forms a connection end; the end surface of the connection end is coated with a light-absorbing material layer, and the light-absorbing material A bare area is provided in the middle of the area covered by the layer, and the outer end surface of the straight section 1-1 is located within the range of the exposed area; the connecting ends of the two chips 1 are spliced together and fixed by a waveguide coupling process. After splicing, the two The straight segments 1-1 on the block chip 1 are coaxial.

[0022] Further, one of the two chips 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com