Diffused light source structure for scanning of linear CCD sensor and assembling method thereof

An assembly method and sensor technology, which are applied in the diffuse light source structure and the assembly field, can solve the problems affecting the scanning sampling accuracy of the CCD sensor, the LED lighting light source is heavy and the inertia is large, and the heat dissipation of the light source is not suitable, and achieves good lighting effect, The effect of convenient modular installation and simple assembly method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

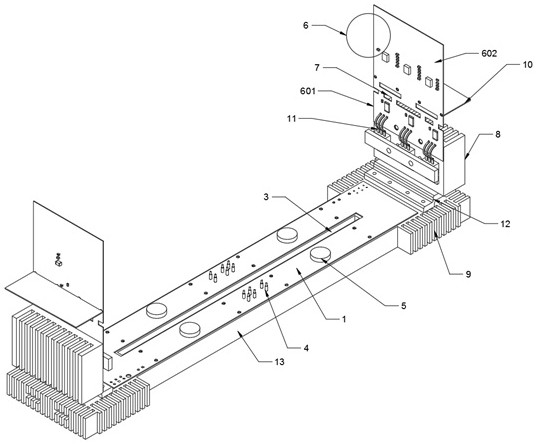

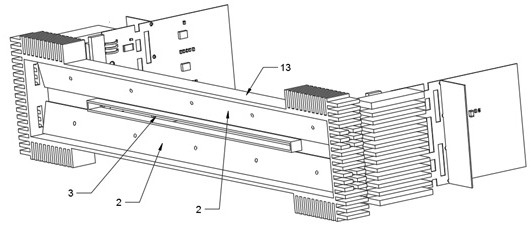

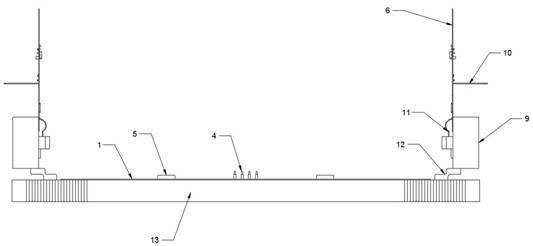

[0046] Such as Figure 1-Figure 3 As shown, the diffuse light source structure used for linear CCD sensor scanning provided by this embodiment includes

[0047] The lampshade 13, the top surface of the lampshade 13 is provided with a power supply circuit board 1, and the top surface of the power supply circuit board 1 is provided with a contact pin 4 for contacting with an external power supply contact to supply power to the lighting part 2;

[0048] The scanning channel 3 is a plate-shaped structure with a long hole in the middle. The scanning channel 3 runs through the power supply circuit board 1 and the lampshade 13 from top to bottom, providing a downward scan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com