Parameterization modeling method for fusion design of diffuser and outlet guide vane

An outlet guide vane and parameterization technology, applied in the field of aero-engines, can solve problems such as widened wake, increased reverse pressure gradient, and OGV design difficulties, achieving the effect of improving efficiency and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

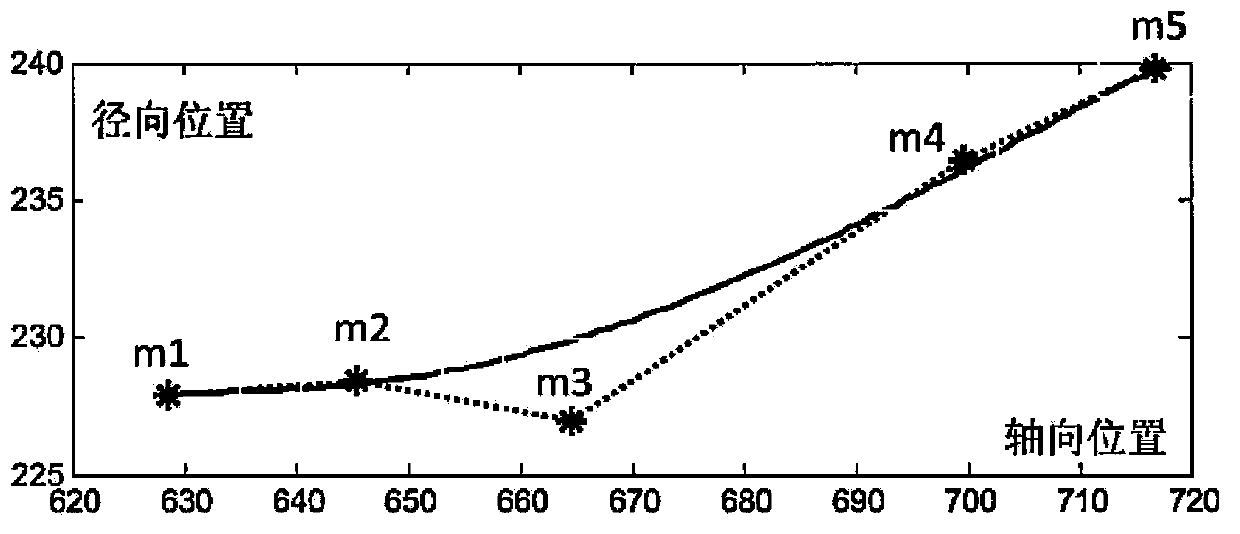

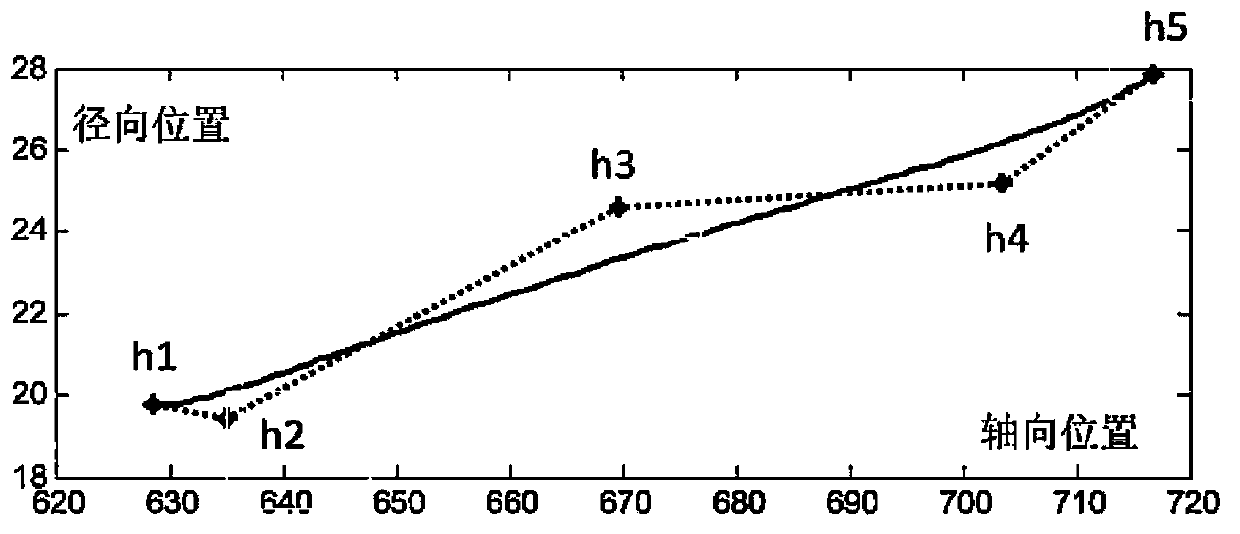

[0024] For the modeling method of the fusion design of OGV and diffuser, it is necessary to flexibly control the geometry of the flow channel with the least parameters, and it is also necessary to meet some constraints of the overall setting. In addition, the flow passage of the OGV / diffuser also needs to be smoothly connected with the flow passage of the final stage rotor. The flow path of OGV / diffuser is determined by the way of centerline plus thickness distribution, the rotor flow path has data of casing (hub) and wheel hub (shroud), and the centerline is unknown.

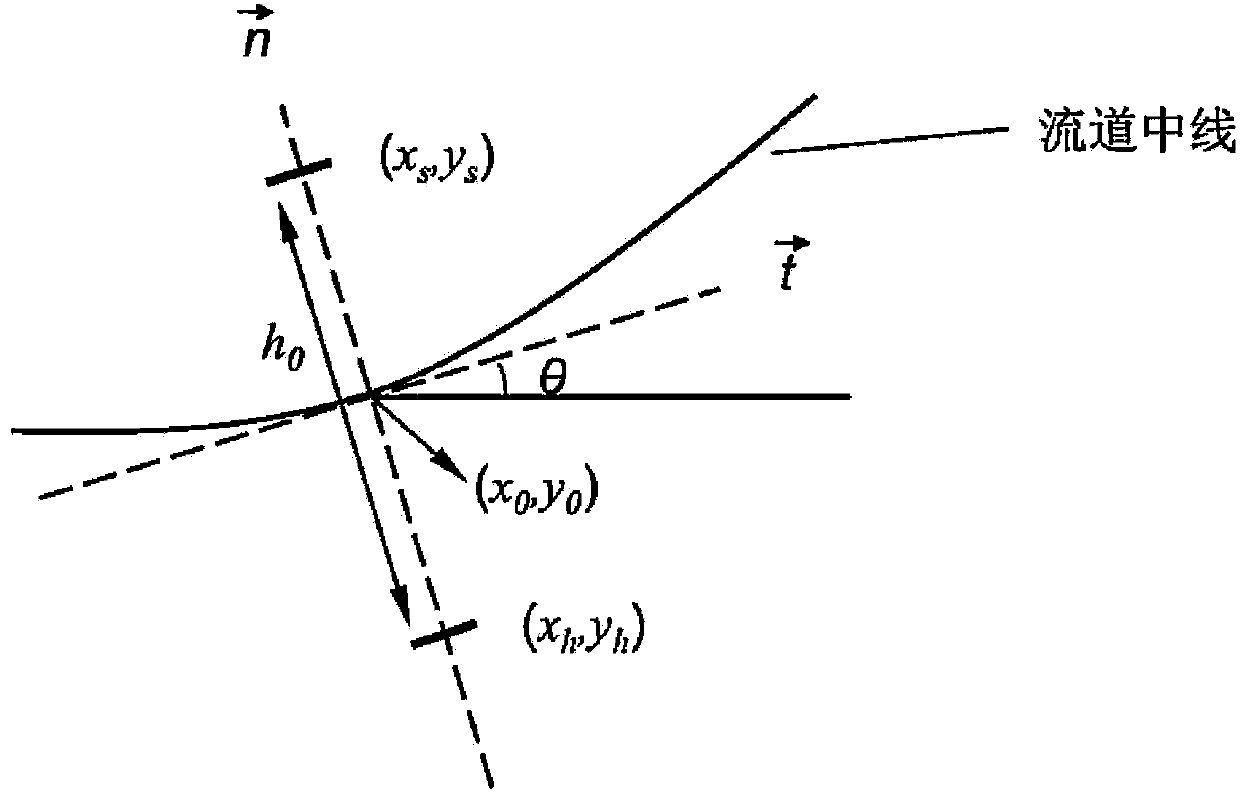

[0025] The modeling method proposed by the present invention adopts the method of increasing the thickness distribution of the center line to shape the flow channel of the OGV / diffuser. Such as figure 1 As shown, the centerline of the runner passes through the point (x 0 ,y 0 ), n is the centerline of the runner at (x 0 ,y 0 ) normal, t is the channel centerline at (x 0 ,y 0 ), the angle between the tang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com