A method of cloth defect detection based on visual saliency

A defect detection and salience technology, which is applied in image data processing, instruments, calculations, etc., can solve problems such as poor direction selectivity, inaccurate positioning, and increased computational complexity, so as to reduce complexity, improve recognition rate, and reduce interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

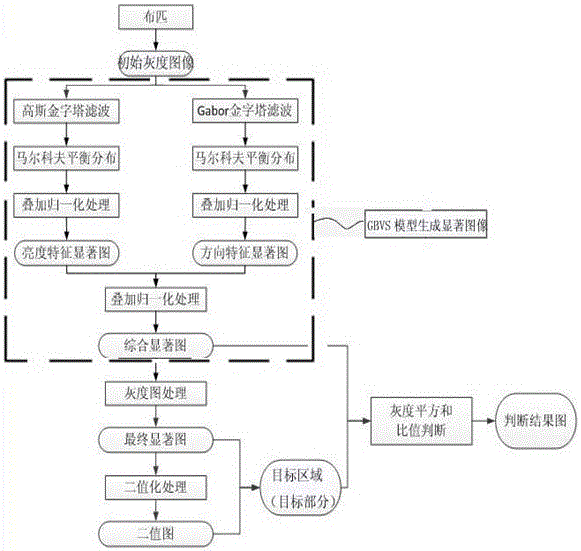

[0030] Example: see figure 1 , as shown in the legend, the above cloth defect detection method includes the following steps:

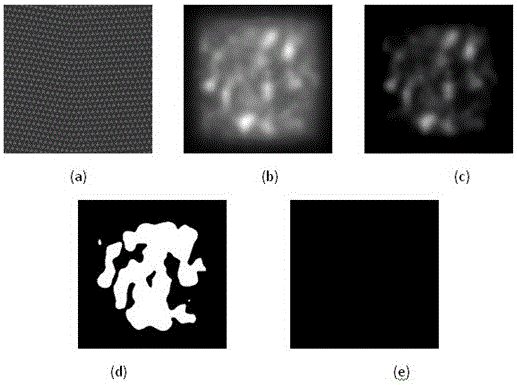

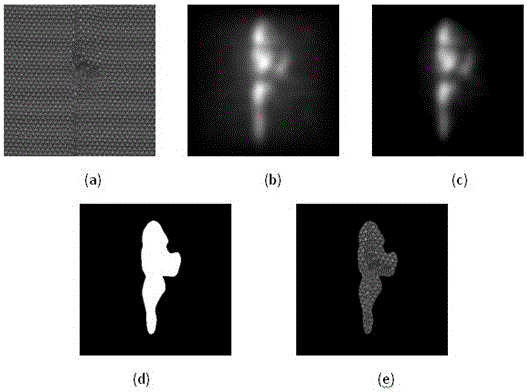

[0031] (1) Collect images, collect images of cloth through industrial cameras, and obtain initial grayscale images ,Such as figure 2 (a) is the initial image of the cloth intact image, such as image 3 (a) is the initial grayscale image of a typical cloth defect image.

[0032] (2), Brightness feature processing:

[0033] a. The above initial grayscale image input through a two-dimensional Gaussian filter Perform Gaussian pyramid filtering. Pyramid filtering refers to continuous 1 / 2 downsampling and filtering of the initial grayscale image. The scale factor of the filter decreases as the image decreases, and a set of filtering results at different scales is obtained. In this example The pyramid level is 2, that is, the filtering results of different brightness features at two scales are obtained, that is, two brightness feature maps ;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com