Motor

A casing and box cover technology, which is applied to electrical components, electromechanical devices, electric components, etc., can solve the problems of poor production process, not easy to operate, and difficult to realize, and achieves good heat dissipation effect, simple structure, and is conducive to cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

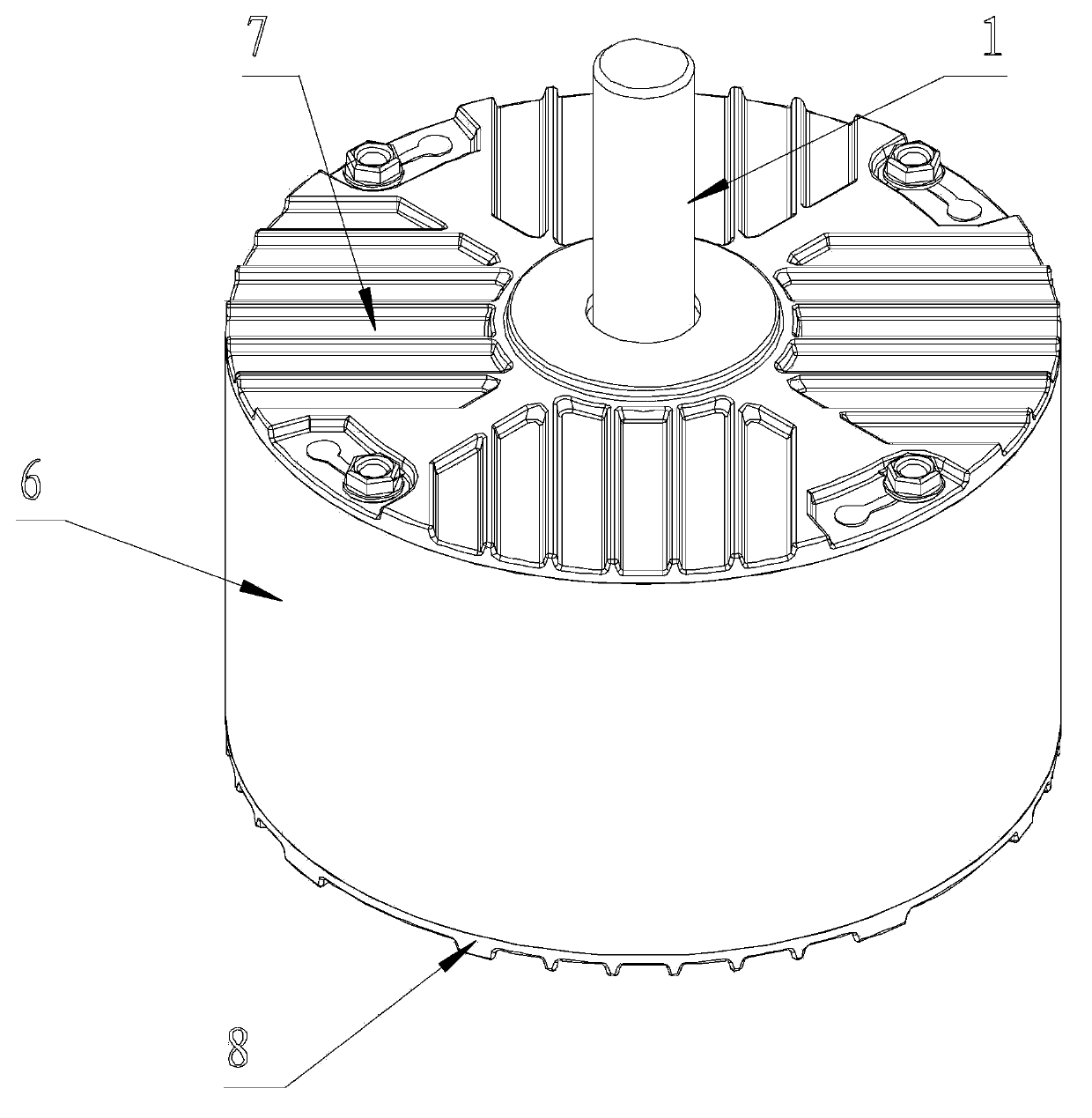

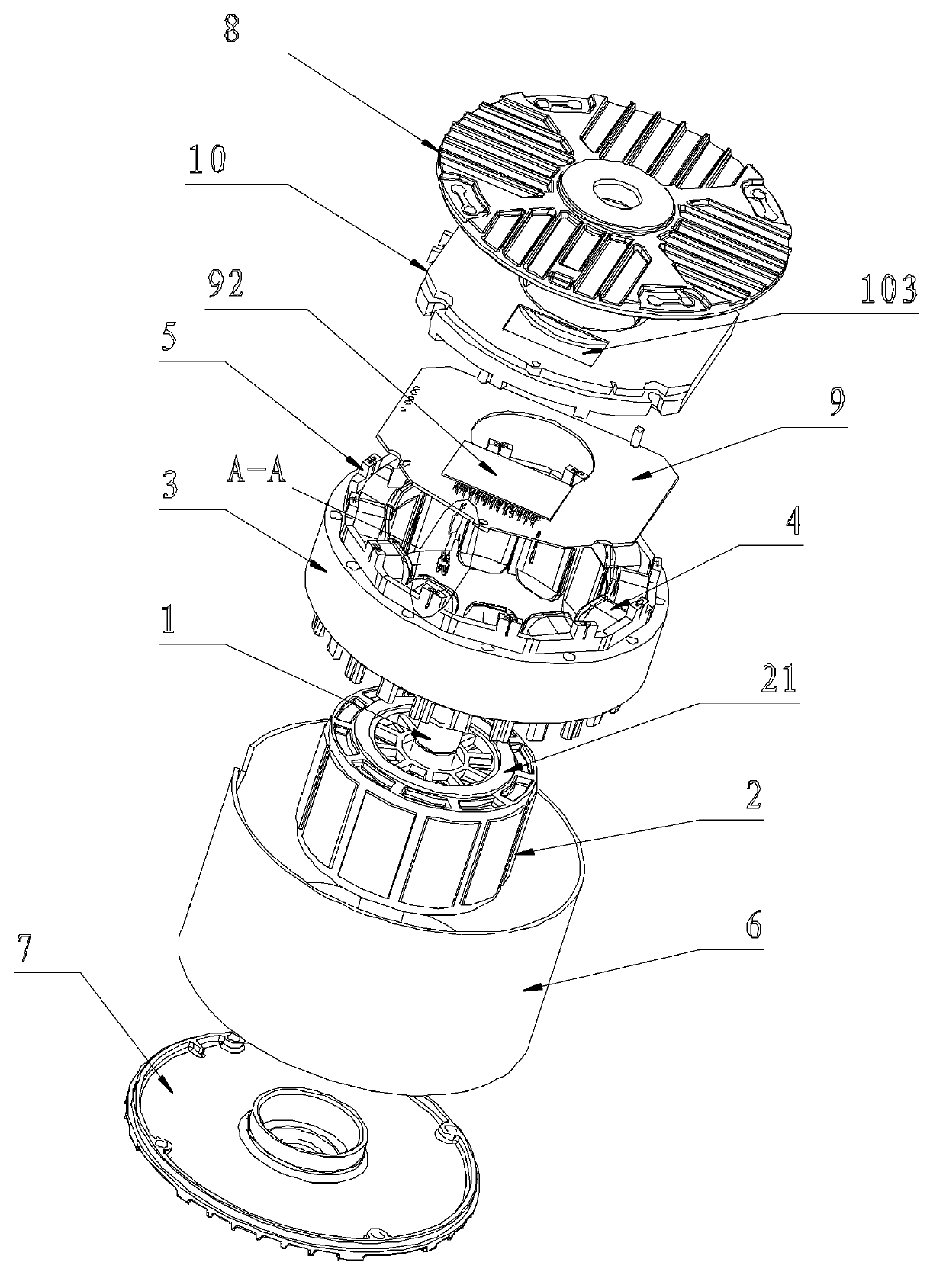

[0023] Embodiment one: if Figure 1 to Figure 6 As shown, the present invention is a motor, including a rotating shaft 1, a rotor assembly 2, a stator core 3, a stator winding 4, end insulation 5, a casing 6, a front end cover 7, a rear end cover 8, a circuit board 9 and a box The cover 10, the rotating shaft 1 and the rotor assembly 2 are connected together, the stator core 3 is set outside the rotor assembly 2, the end insulation 5 is installed on the end face of the stator core 3, the stator winding 4 is wound on the stator core 3, and the stator iron core The core 3 and the casing 6 are connected together, the front end cover 7 and the rear end cover 8 are installed at both ends of the casing 6, the rotating shaft 1 is supported on the bearings of the front end cover 7 and the rear end cover 8, and the box cover 10 is installed on the rear end cover 8 On the inner bottom surface, the circuit board 9 is installed in the box cover 10, and it also includes a connecting wire c...

Embodiment 2

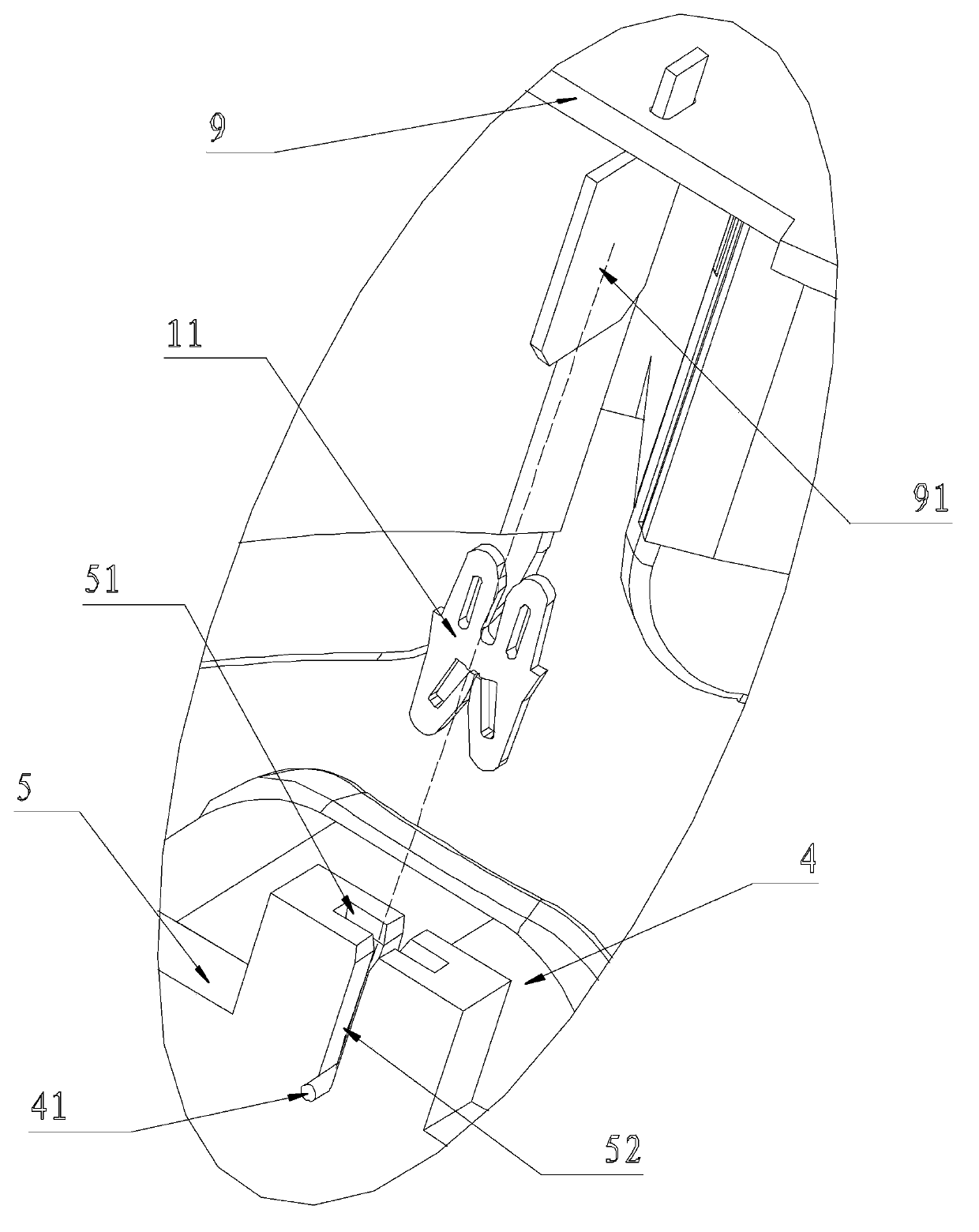

[0024] Embodiment 2: On the basis of Embodiment 1, the following technical features are added: a groove 51 is opened on the end insulation 5, a gap 52 is provided in the middle of the groove 51 and on the end insulation 5, and the gap 52 communicates with the groove 51 , the wire end 41 of the stator winding 4 is embedded in the gap 52, the connecting wire clip 11 is clamped in the groove 51 and the tail of the connecting wire clip 11 clamps the wire end 41 of the stator winding 4, and the tail of the insert piece 91 is inserted into the gap 52 and is connected by the wire Clamp 11 ends are clamped.

Embodiment 3

[0025] Embodiment 3: On the basis of Embodiment 1 or Embodiment 2, the following technical features are added: the insertion piece 91 is welded on the circuit board 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com