Method for manufacturing a stator of an electric machine, stator and electric machine

A stator and rotor technology, used in the field of stators, stators and motors for manufacturing motors, can solve the problems of reducing motor power intensity, high material cost, high scrap rate, etc., to improve concentricity, minimize cost, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

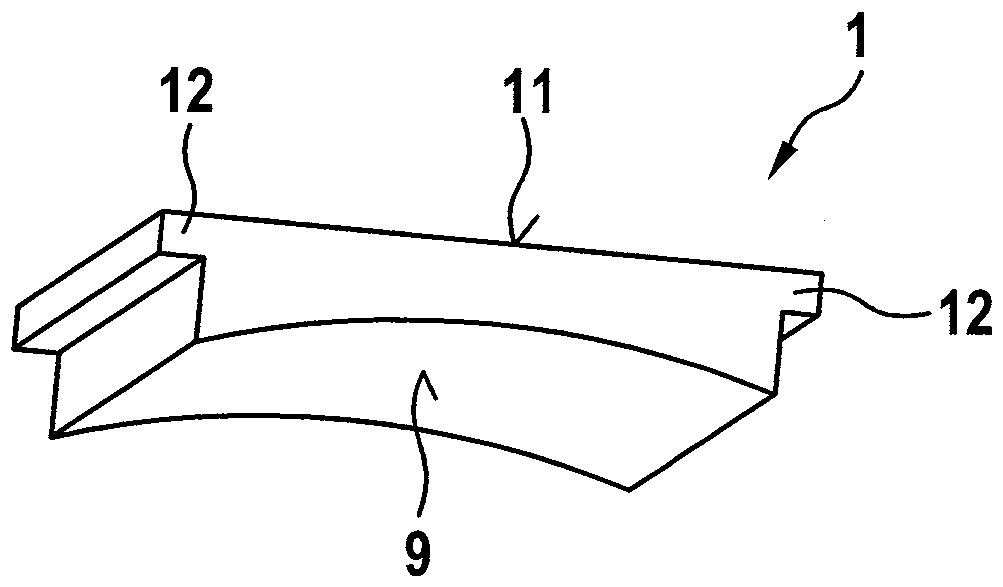

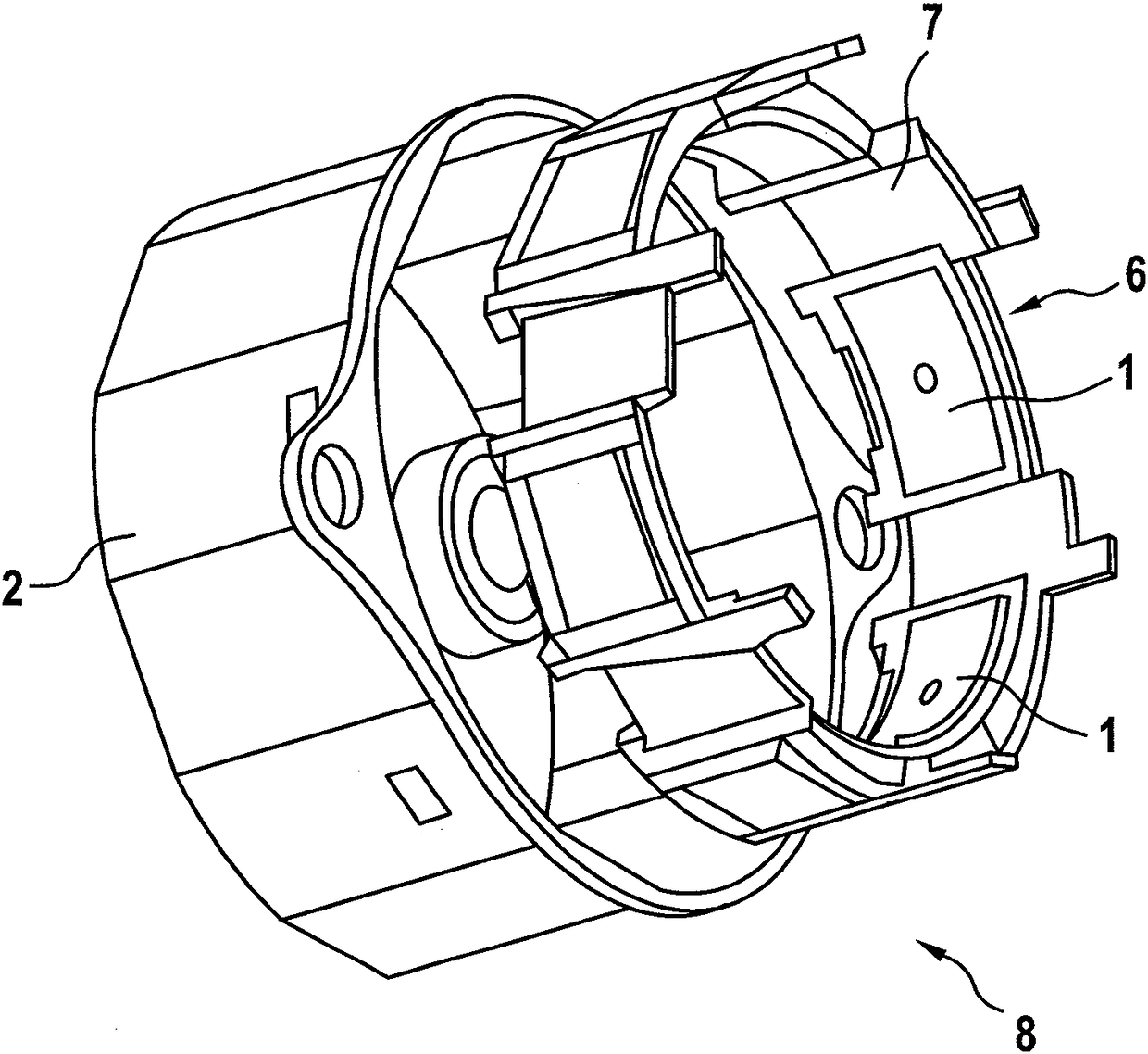

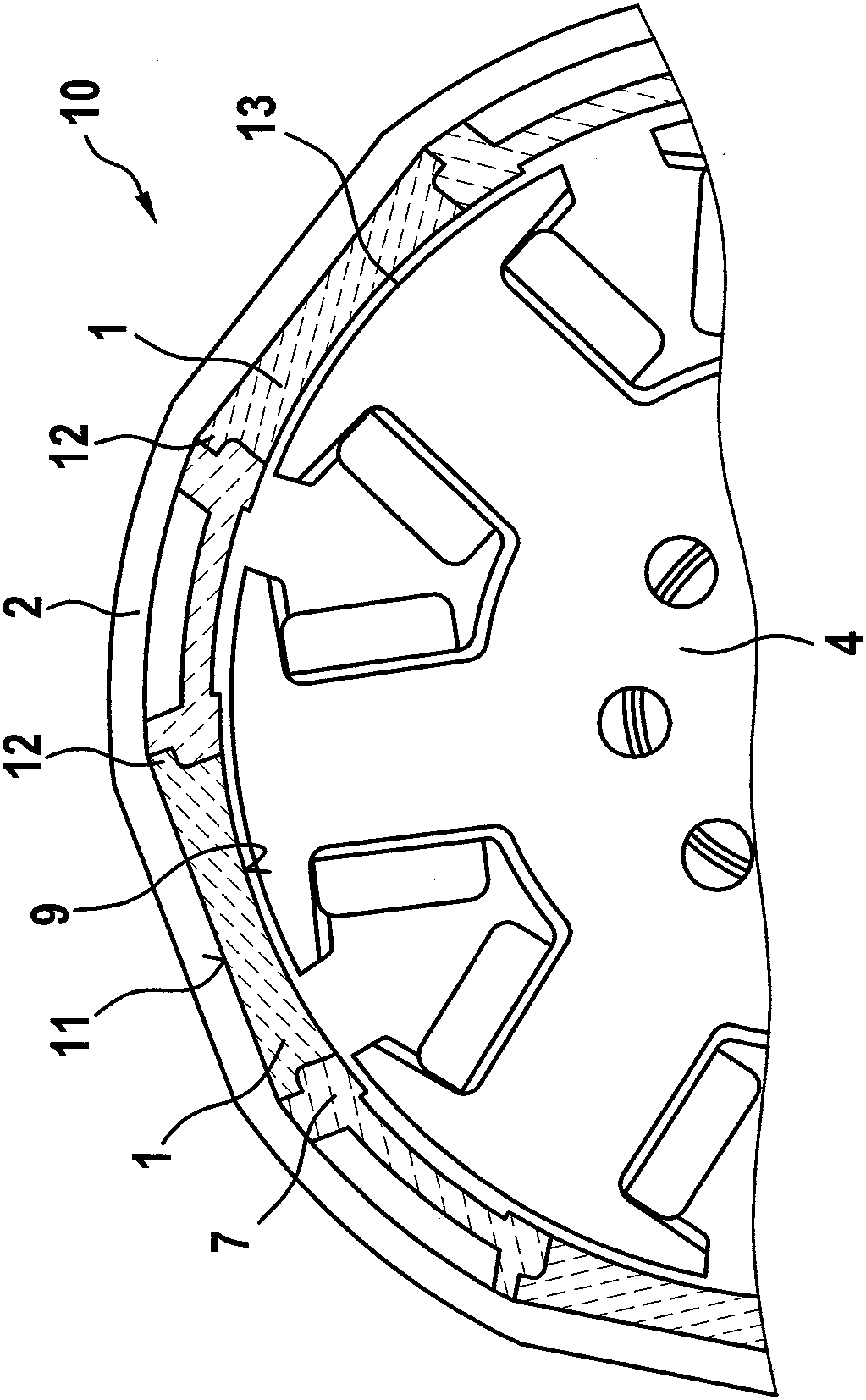

[0030] figure 1It is a schematic plan view of an electric machine 10 according to a first advantageous development of the invention. The electric machine 10 comprises four magnetic elements 1, 1a and a pole piece 2, wherein the magnetic elements 1, 1a are injected directly into the pole piece 2 by means of injection molding, whereby a The material fits the connection. The letters "S" and "N" designate the respective polarity of the member. There is no air gap between the magnetic elements 1 , 1 a and the pole piece 2 , so that the magnetic flux is uniform and the power density of the electric machine 10 is very good. Furthermore, the pole piece has two undercuts 3 , by means of which a form-fit connection is formed between the magnetic element 1 a and the pole piece 2 , which improves the positioning of the magnetic element 1 a on the pole piece 2 . This has a positive effect on the mechanical stability of the motor 10 . Furthermore, the electric machine 10 also includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com