No-magnetic-resistance type direct current generator

A DC generator and reluctance technology, applied in DC commutators, electrical components, electromechanical devices, etc., can solve the problems of hindering the rotation of the rotor and requiring high power for the rotation of the rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

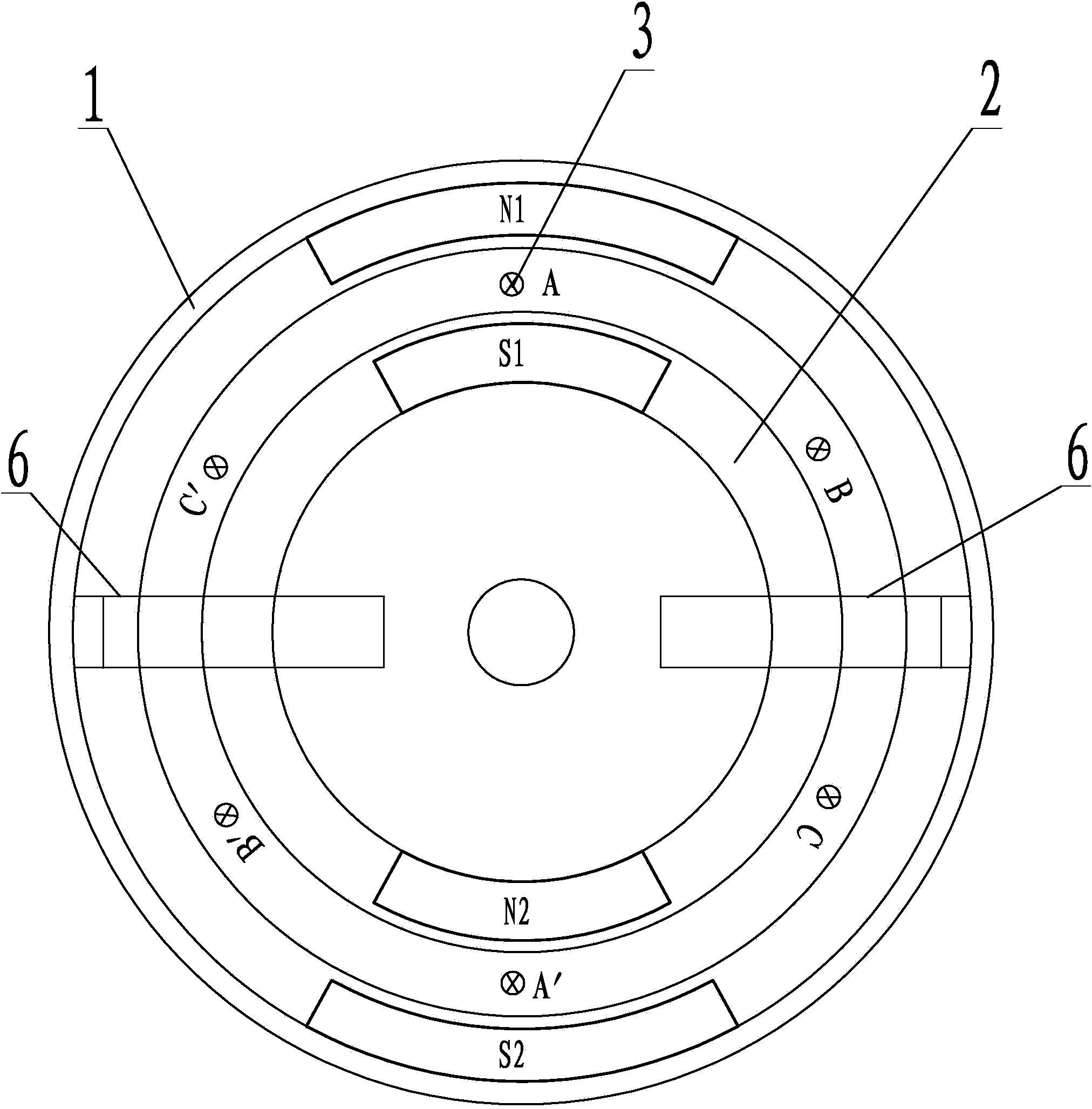

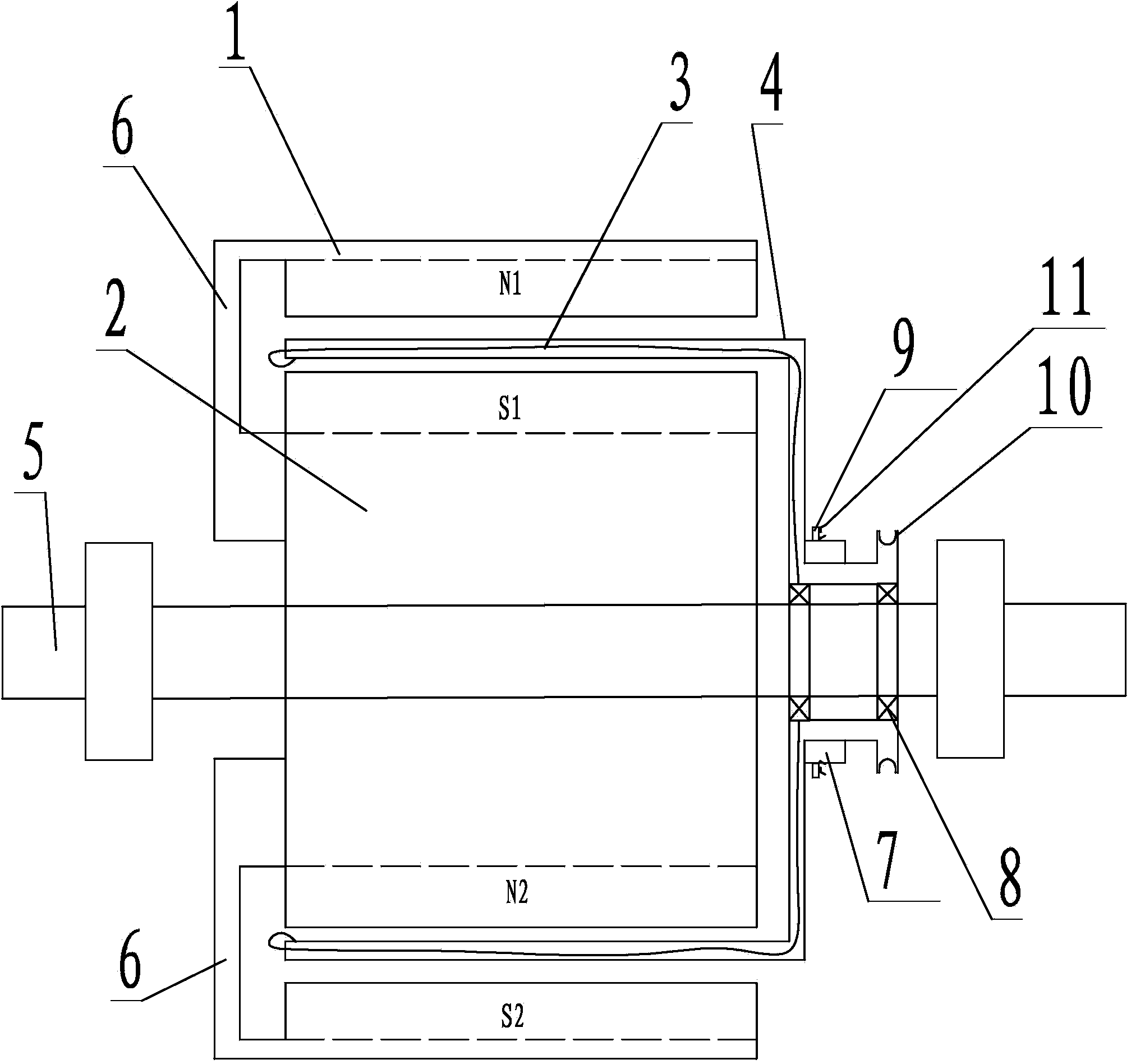

[0012] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0013] combine figure 1 —— figure 2 As shown, a non-reluctance DC generator consists of a casing 1, a core 2, a coil 3, a coil carrier 4, a central shaft 5, a connecting arm 6, a commutator 7, a bearing 8, a carbon brush 9, and a coil carrier Belt pulley 10, direct current output conversion switch 11 etc. are formed.

[0014] The casing 1 and the core 2 are annular parts made of magnetically permeable materials, which are the same as those used for stators and rotors in traditional generators, such as silicon steel sheets. The casing 1 is set outside the movement 2, and there is a gap between the inner wall of the casing 1 and the outer wall of the movement 2, usually about 1 cm, so that the coil carrier 4 wrapped with the coil 3 can extend into the gap. The casing 1 and the movement 2 are fixedly connected together by the connecting arm 6, and then f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com