Heat-generating inductor for high-frequency soldering station and manufacturing method thereof

A manufacturing method and high-frequency welding technology, which is applied in the manufacture of inductors/transformers/magnets, inductors, fixed inductors, etc., can solve the problems of reduced thermal energy efficiency and easy damage of inductor coils, and achieve the efficiency of converting electrical energy into heat energy Reduce and solve the effect of fragile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

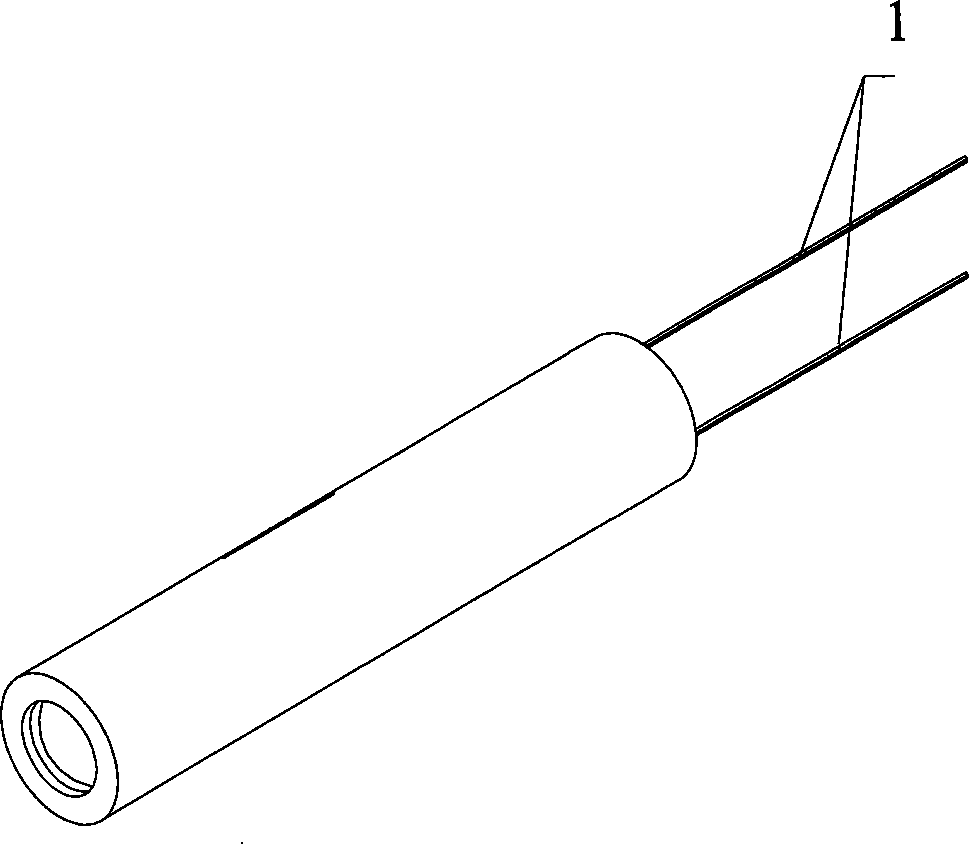

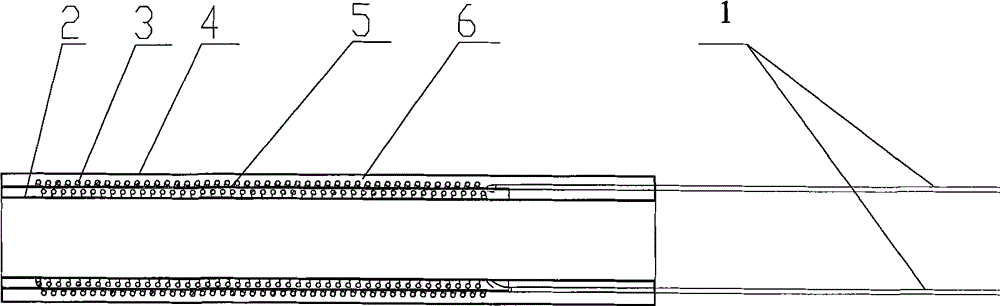

[0023] Such as figure 1 , 2 As shown, a heating inductor for a high-frequency soldering station includes an inner skeleton, an inductance coil wound on the skeleton and connected to an external power line 1, and a bushing sleeved on the periphery of the inductance coil. The inner skeleton is made of ceramic material The finished ceramic inner tube 2, the casing is a ceramic outer tube 4 made of ceramic material, the space between the ceramic inner tube and the ceramic outer tube is filled with a sealed ceramic intermediate layer, the inductance coil is a wound double-layer electromagnetic wire 3, and the double-layer An insulating layer 5 made of high temperature resistant insulating material such as high temperature glass fiber cloth or mica paper is arranged between the electromagnetic wires 3 .

Embodiment 2

[0025] A heating inductor for a high-frequency soldering station and a manufacturing method thereof, comprising the following steps:

[0026] 1. Evenly wind the first layer of magnet wire on the ceramic inner tube to keep a sufficient distance between turns;

[0027] 2. Spread a layer of colloidal ceramic powder on the first wound magnetic wire, and add an insulating layer made of high temperature resistant insulating material, such as high temperature glass fiber cloth or mica paper;

[0028] 3. Use the same magnet wire to wind the second layer of magnet wire evenly outside, so as to keep a sufficient distance between turns;

[0029] 4. Spread a layer of colloidal ceramic powder on the second layer of coil that has been wound, and put on the ceramic outer tube;

[0030] 5. According to the heating characteristics of the ceramic powder used, heat it in a kiln or oven to form a heating inductor for a high-frequency soldering station with an inductance coil inside.

[0031] A....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com