Multi-center iron core coil-free permanent magnet motor

A technology of ironless coils and permanent magnet motors, which is applied to wind power motor combinations, synchronous motors with stationary armatures and rotating magnets, engines, etc., which can solve the problems of large motor diameter, high production cost, and low power generation efficiency , to achieve the effects of increased output power, low cost, and high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

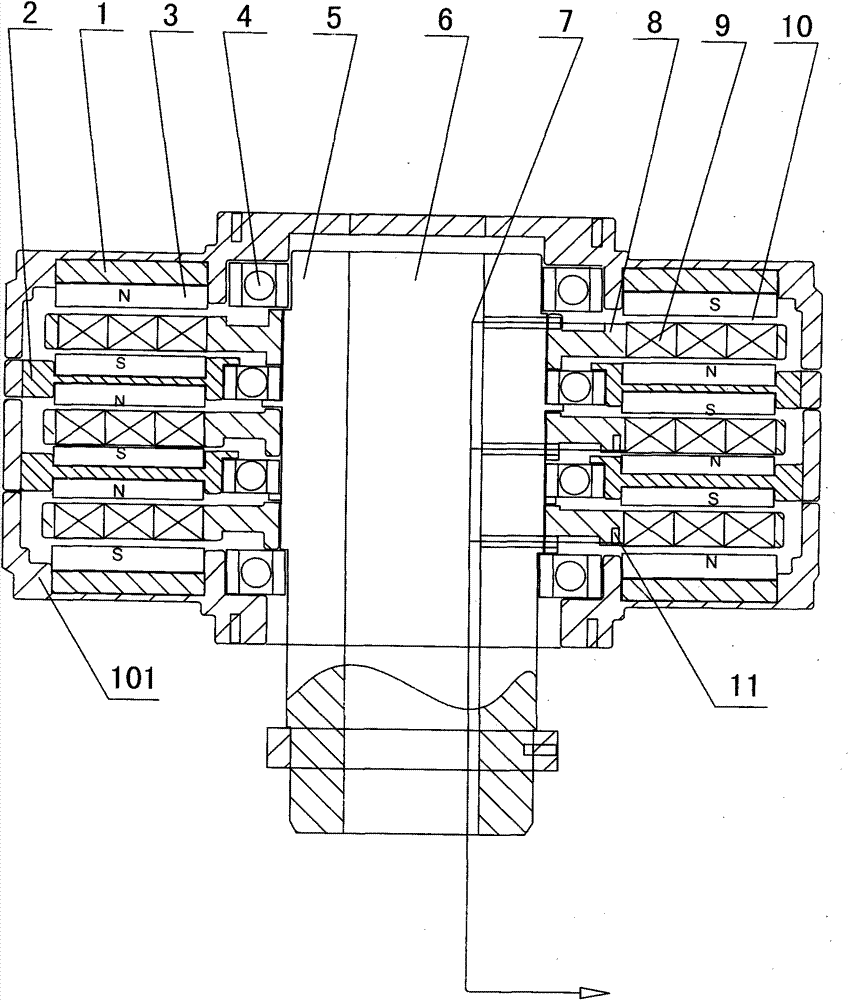

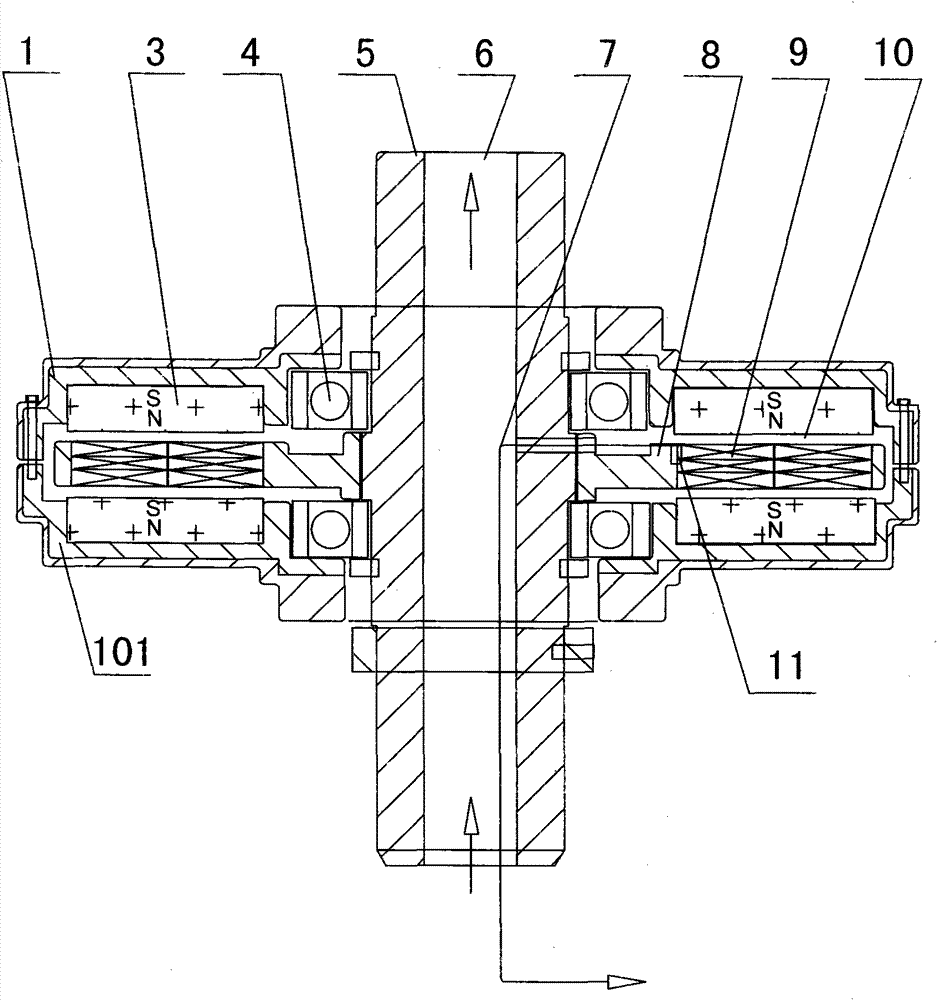

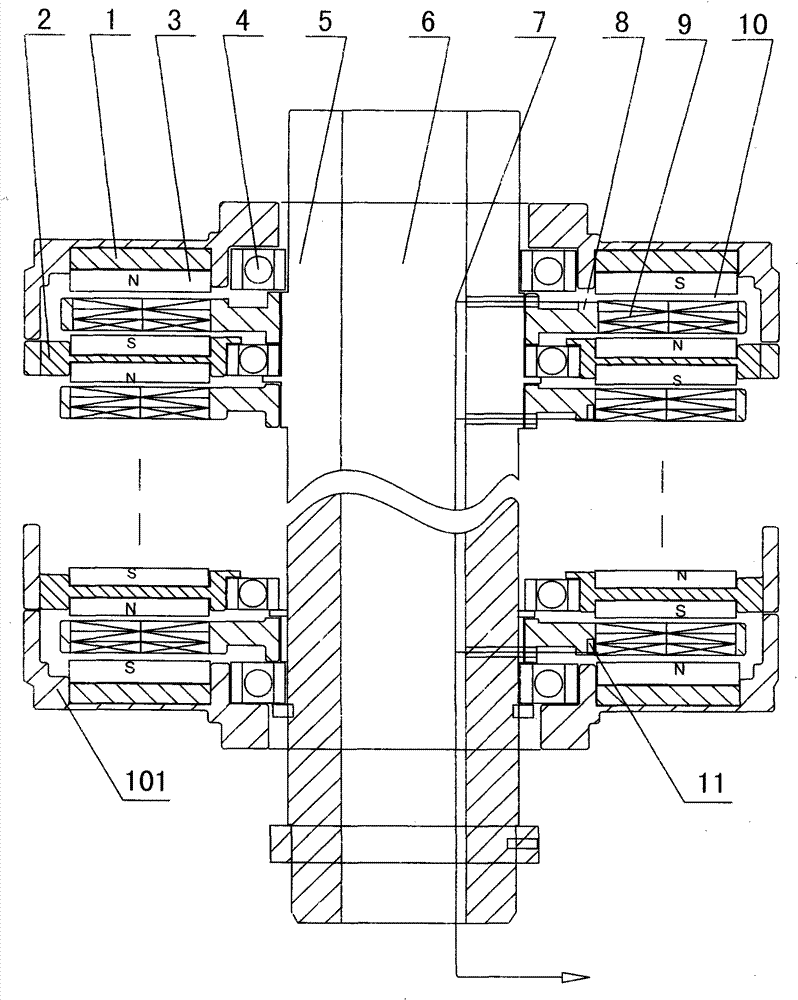

[0025] Example: attached figure 1 , a cross-sectional diagram of the structural principle of a multi-center coreless coil permanent magnet motor. The moving plate is made of round steel, with a bearing 4 in the center and an armored permanent magnet 3 on the inner wall. As a preference, the permanent magnet 3 is made of neodymium-iron-boron magnet steel, and 36 permanent magnets 3 are respectively arranged on the first moving plate along the circumference. Disk 1, the inner side of the second moving disk 101, both sides of the middle moving disk 2, and three static disks 8, according to the first moving disk 1--static disk 8--middle moving disk 2--static disk 8--middle moving disk 2--Static plate 8--The order of the second moving plate 101, superimposed and combined fixed on the main shaft 5, there is an air gap 10 between each moving disc and the static disc, the main shaft 5 is a non-moving body, controlled by stainless steel The lower end is provided with a positioning gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com