Cam transmission mechanism of spinning fishing reel

A technology of cam drive and fishing reel, which is used in transmission devices, fishing reels, mechanical equipment, etc., can solve the problems of inability to complete uniform wiring, high cost, and difficulty in manufacturing, and achieves simple and compact structure. The effect of quality wiring and uniform wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

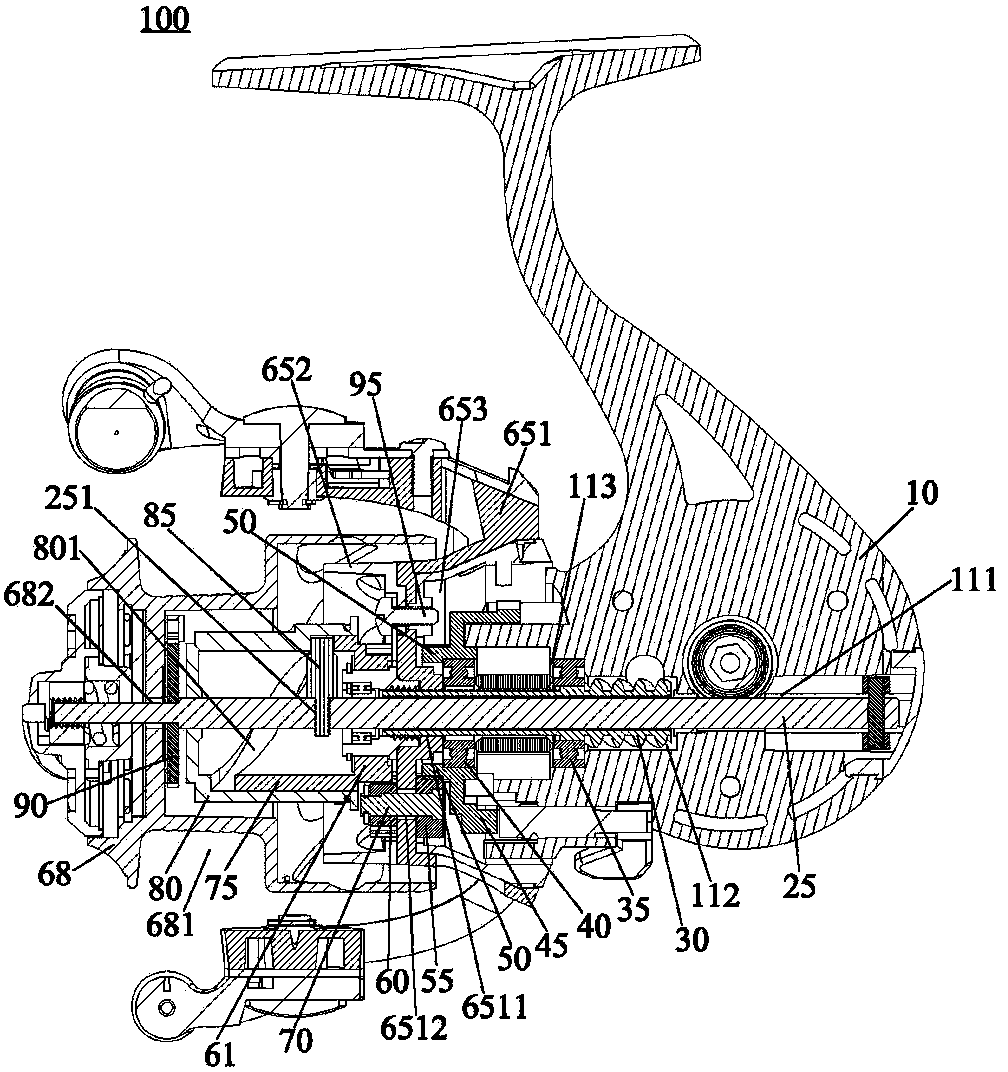

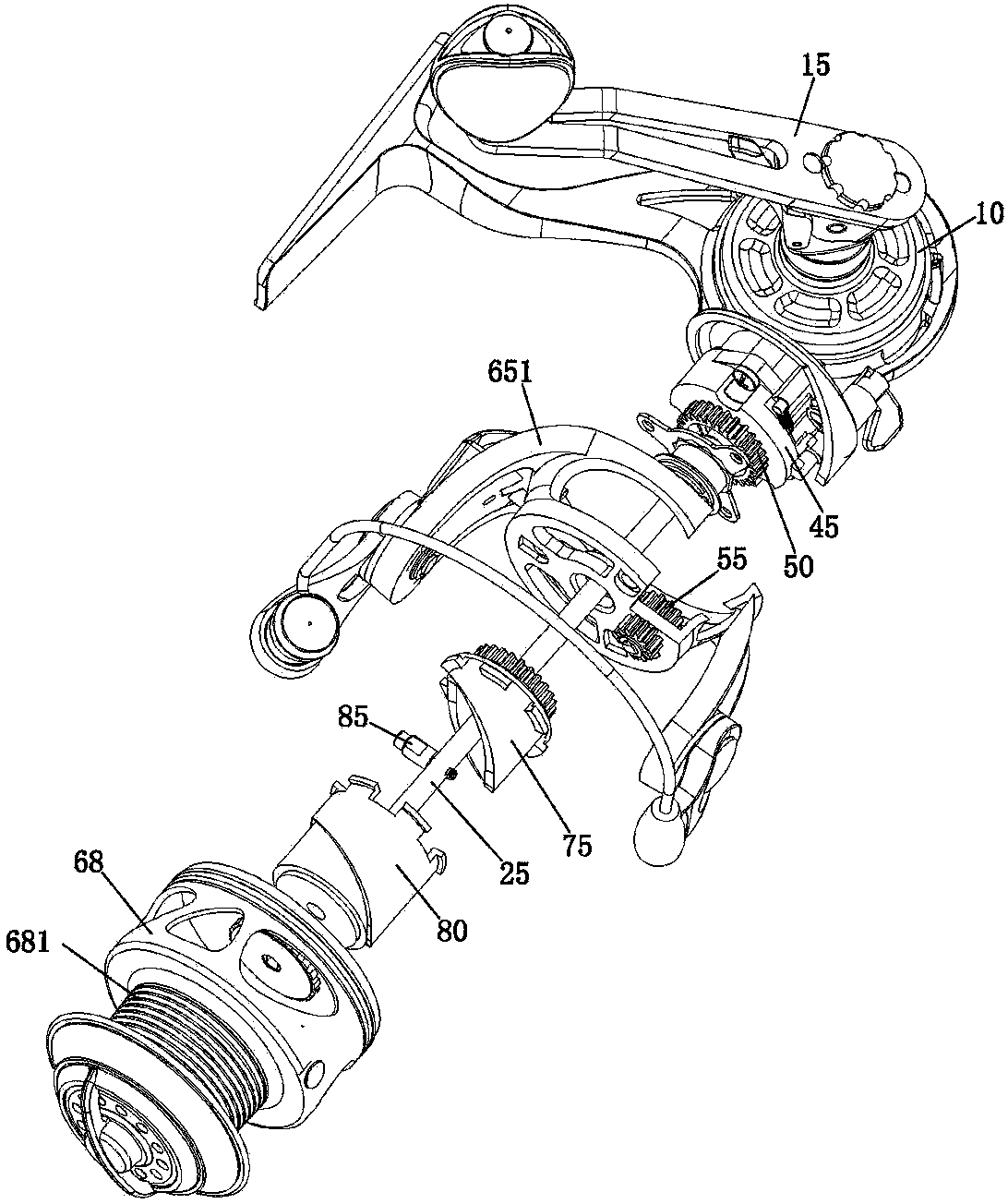

[0014] refer to Figure 1 to Figure 4 , the spinning wheel type fishing reel cam transmission mechanism 100 of the present invention includes a fishing reel main body 10, a rocker arm 15, a rocker arm transmission assembly, a main shaft 25, a gear rod 30, a first bearing 35, a second bearing 40, a bearing holder 45, a first Gear 50 , second gear 55 , third gear 60 , fourth gear 61 , wire housing assembly 65 , wire wheel 68 , gear shaft 70 , first cam 75 , second cam 80 and transmission pin 85 .

[0015] The rocker arm transmission assembly is placed in the main body 10 of the fishing reel. The input end of the rocker arm transmission assembly is connected to the rocker arm 15 . The main body of the fishing reel 10 is provided with a main shaft hole 111 running forward and backward. A rack housing chamber 112 and a bearing housing chamber 113 are connected in sequence in front of the main shaft hole 111 . The rear end of the gear rod 30 and the first bearing 35 are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com