Cooked flake wrapping machine

A technology of a cake pressing machine and a pressing plate is applied in the field of cake pressing machines, which can solve the problems of rapeseed cake prone to accidents, low work efficiency, hidden dangers, etc., and achieve the effects of solving low efficiency, improving work efficiency, and ensuring the safety of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

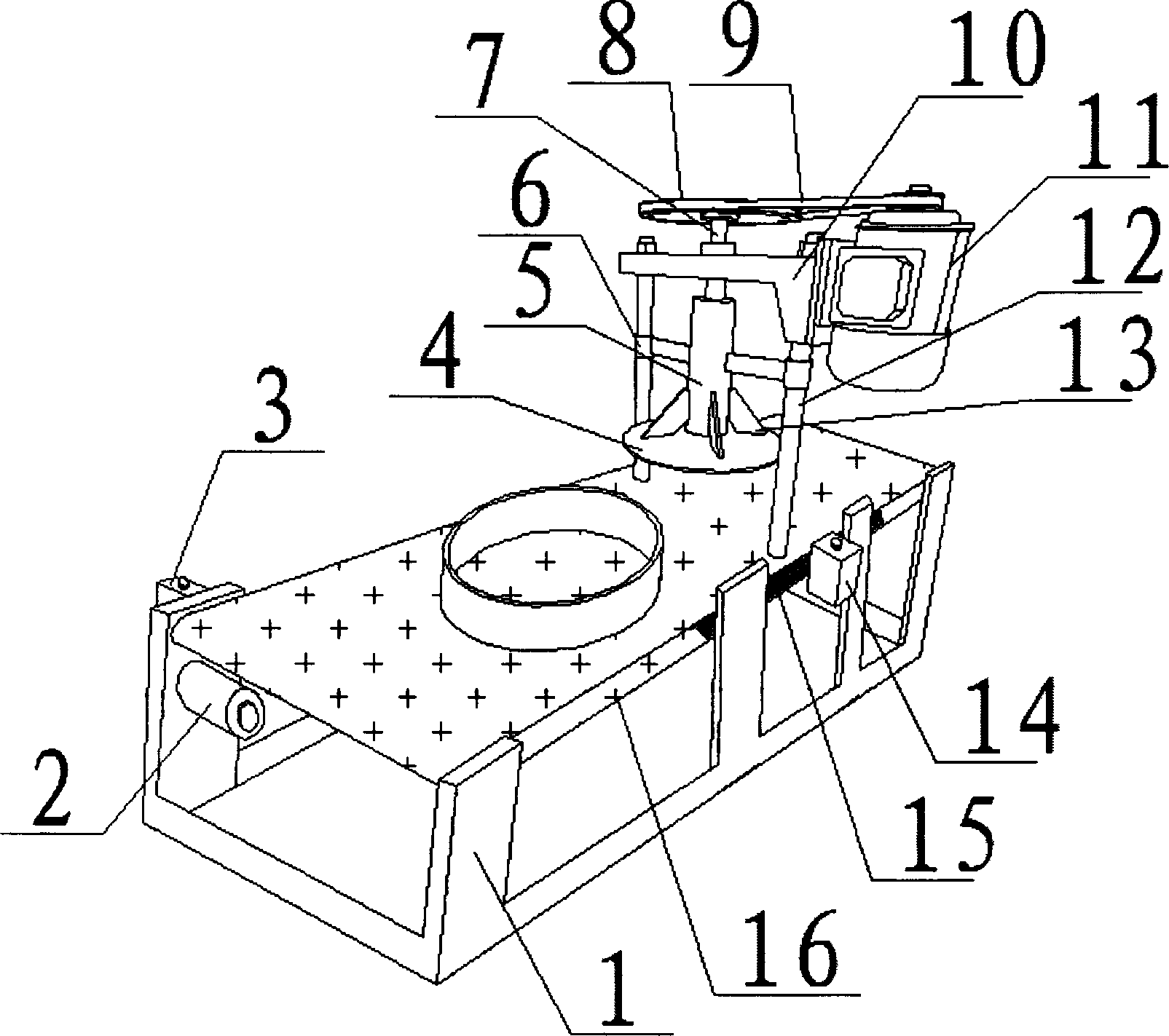

[0012] Referring to the drawings, a cake pressing machine includes a base 1, a conveyor belt 16 is provided on the base 1, and the conveyor belt 16 is connected to a motor 2 through a belt. There are two guide rods 12 in the middle of the base 1, and the guide rods 12 are provided with The matching sliding sleeve 6, the sliding sleeve 6 is connected with the threaded sleeve 5 through a connecting rod, the bottom of the threaded sleeve 5 is provided with a lower pressure plate 4, the threaded sleeve 5 is provided with a screw 7 and the top of the screw 7 is fixed with a hub 8 and a guide rod 12 The top is provided with a cross beam 10, the side of the cross beam 10 is provided with a motor two 11, the motor two 11 is connected to the hub 8 through a belt 9, and a support plate 15 is provided inside the conveyor belt 16 directly under the lower plate 4, and a control motor one 2 is provided at the front end of the base 1 The switch 3 of the base 1 is provided with a switch 14 for ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap