Multi-station hot mold centrifuge production system

A production system, technology of hot mold method, applied in the field of centrifugal casting machine, to achieve the effect of easy operation, high safety factor and cleanliness for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

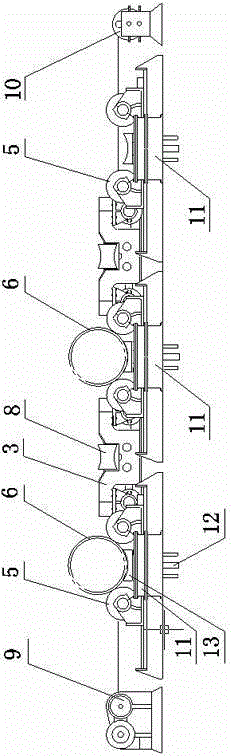

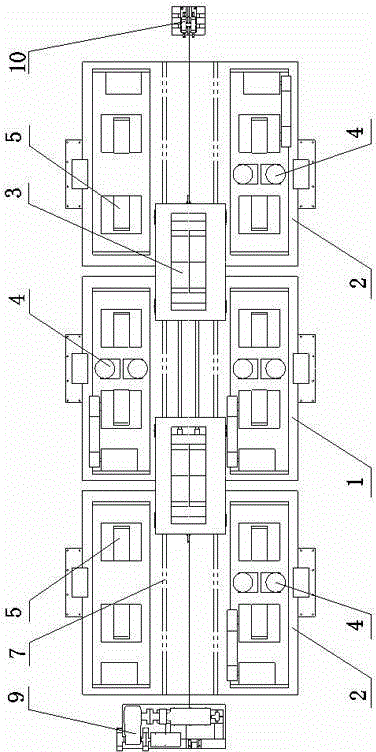

[0019] Such as figure 1 , 2 A kind of multi-station thermal mold method centrifuge production system shown, comprises horizontal centrifugal casting pipe drawing device 1, and the two ends of described horizontal centrifugal casting pipe drawing device 1 are also provided with pipe mold elevating device 11; The two sides of the horizontal centrifugal casting tube pulling device 1 are respectively equipped with spraying cleaning devices 2, and the two ends of the two spraying cleaning devices 2 are provided with pipe mold lifting devices 11, and the spraying cleaning device 2 includes a roller mechanism 5 , to facilitate the spraying or cleaning operation of the pipe mold 6, the central axis position of the horizontal centrifugal casting pipe drawing device 1 and the spray cleaning device 2 is provided with a pipe mold transposition t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com