Interlocking device for lifting and limiting of ladle cover of vertical heating device and using method thereof

A technology of lifting limit and interlocking device, which is used in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problem of frequent limit failure and other problems, and achieve the effect of remarkable use effect, convenient control and reliable action.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

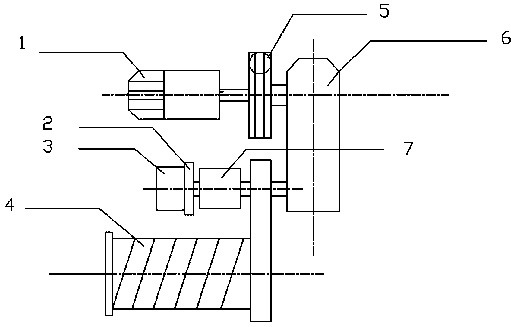

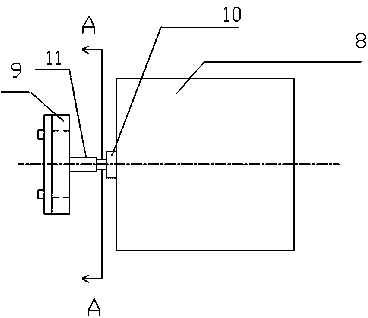

[0025] It can be seen from the accompanying drawings that a vertical toaster cover lifting limit interlocking device includes: a support frame 2, a height limiter 3, and a reducer intermediate shaft 7, and is characterized in that: the vertical toaster cover The lifting limit is controlled by a height limiter 3, which is connected to the end of the shaft 7 in the reducer, and the height limiter 3 is fixed on the support frame 2. The use of the height limiter 3 effectively solves the problem of frequent failure of the previous limit. The use of the height limiter 3 is reliable in action, convenient in control and remarkable in use. The limit can be adjusted arbitrarily according to the height of the cover, which improves the effectiveness and flexibility of equipment inspection and maintenance. The height limiter 3 can realize multiple outputs, and each output can realize interlock control independently, and the height limiter can be used to realize a single interlock control, ...

Embodiment 2

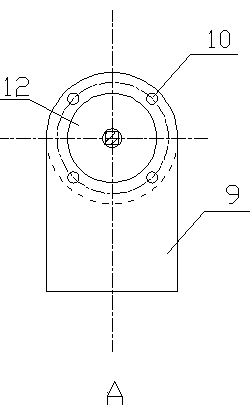

[0027] As an improvement of the present invention, the support frame 2 is made of a steel plate for fixing the height limiter, and is provided with a fixing threaded hole 10, a height limiter 3 bearing through holes, and the support frame 2 is fixed on the oven On the base, after adopting this design, the rigidity of the height limiter 3 can be improved, and the precision of the height limiter 3 can be improved. The rest of the structural features and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0029] As an improvement of the present invention, the front end of the rotating shaft 7 of the reducer is provided with a concentric groove 11, the groove 11 is square and embedded with the reel shaft of the height limiter, and the depth is 1-2cm. After this design, it is convenient to connect the height limiter with the reduction box, which can ensure the working stability of the height limiter and improve work efficiency. All the other structures and advantages are identical to Embodiment 1.

[0030] The present invention can also combine at least one of the technical features described in embodiments 2 and 3 with embodiment 1 to form a new implementation.

[0031] The present invention, concrete use process is as follows:

[0032] (1) The rotation of the motor drives the rotation of the shaft in the reducer;

[0033] (2) The rotation of the intermediate shaft drives the rotation of the height limiter reel;

[0034] (3) The reel shaft drives the worm and the worm wheel t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com