Working table for installing mechanical seal of water pump

A mechanical seal and workbench technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of mechanical seal sealing performance reduction, short service life, poor assembly quality, etc., and achieve high sealing performance and long service life , the effect of high assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

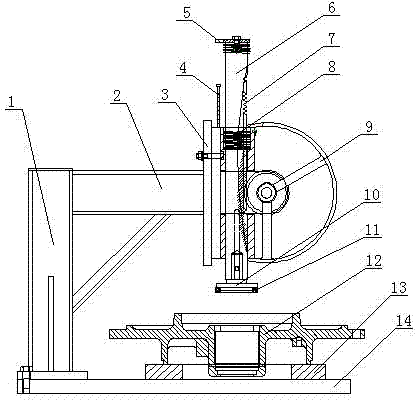

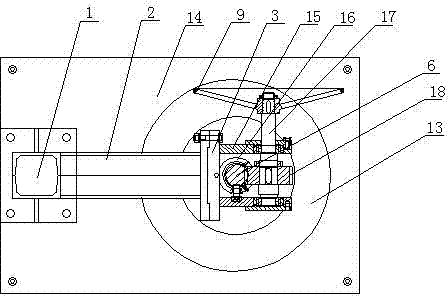

[0010] Such as figure 1 , figure 2 The water pump mechanical seal installation workbench shown includes a workpiece table 14, a support frame 1, a support arm 2, a mounting base 3, a sliding sleeve 16, a sliding rod 6, a support 15, a handwheel shaft 17, a handwheel 9, an assembly port, Lifting rack 7, gear 18, catch and return spring 8, the above-mentioned structure is the same as the prior art, no more details, the present invention is characterized in that the workpiece table 14 is provided with an annular pump cover seat 13 opposite to the lower end of the sliding rod 6 , the lower end of the sliding rod 6 is provided with a sealing ring pressing plate 10, the sealing ring pressing plate 10 is provided with a buffer pressing pad 11, the upper part of the mounting seat 3 is provided with a vertical threaded hole, and the threaded hole is provided with a stroke adjustment bolt 4, and the upper end of the sliding rod A limit block 5 matched with the stroke adjusting bolt 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com