Supporting frame for machining turbine high pressure outer cylinder back oblique pipe orifice through boring machine facing head

A boring machine flat rotary disk, high-pressure outer cylinder technology, applied in the direction of metal processing machinery parts, metal processing equipment, support, etc., can solve the problems of time-consuming and labor-intensive, and achieve the effect of simple processing technology, convenient purchase and installation, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

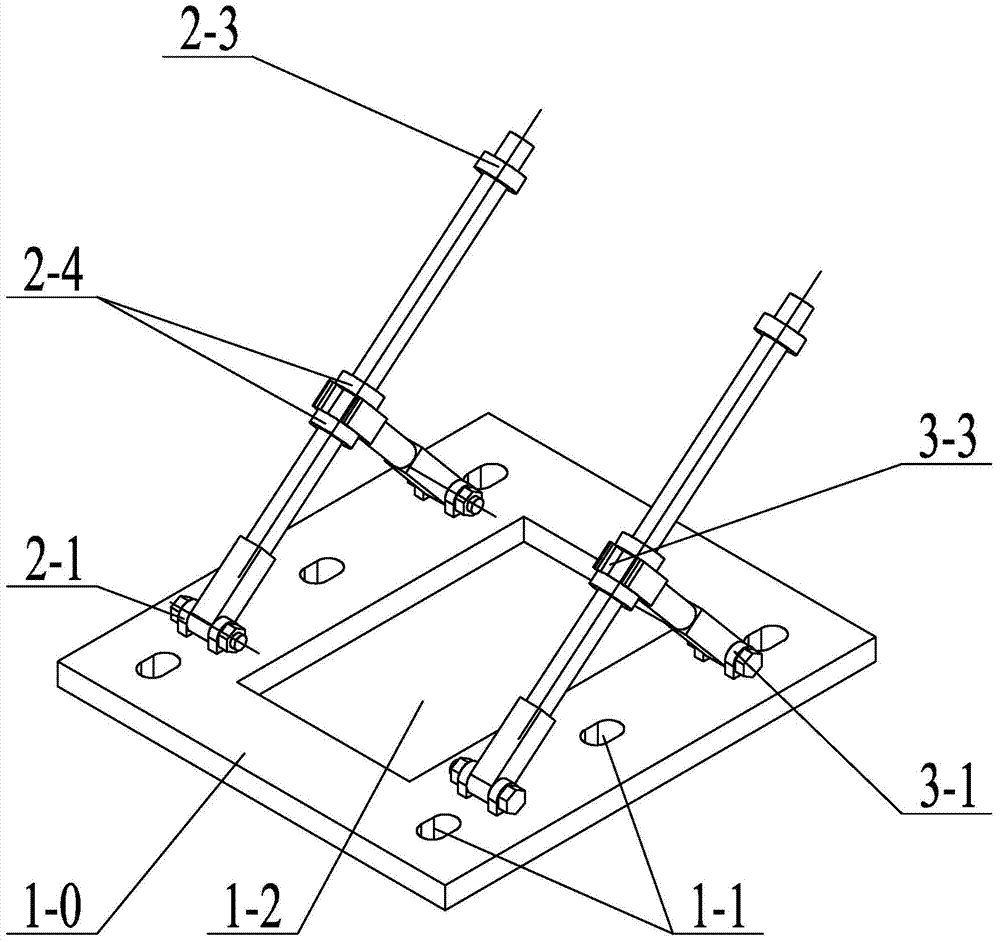

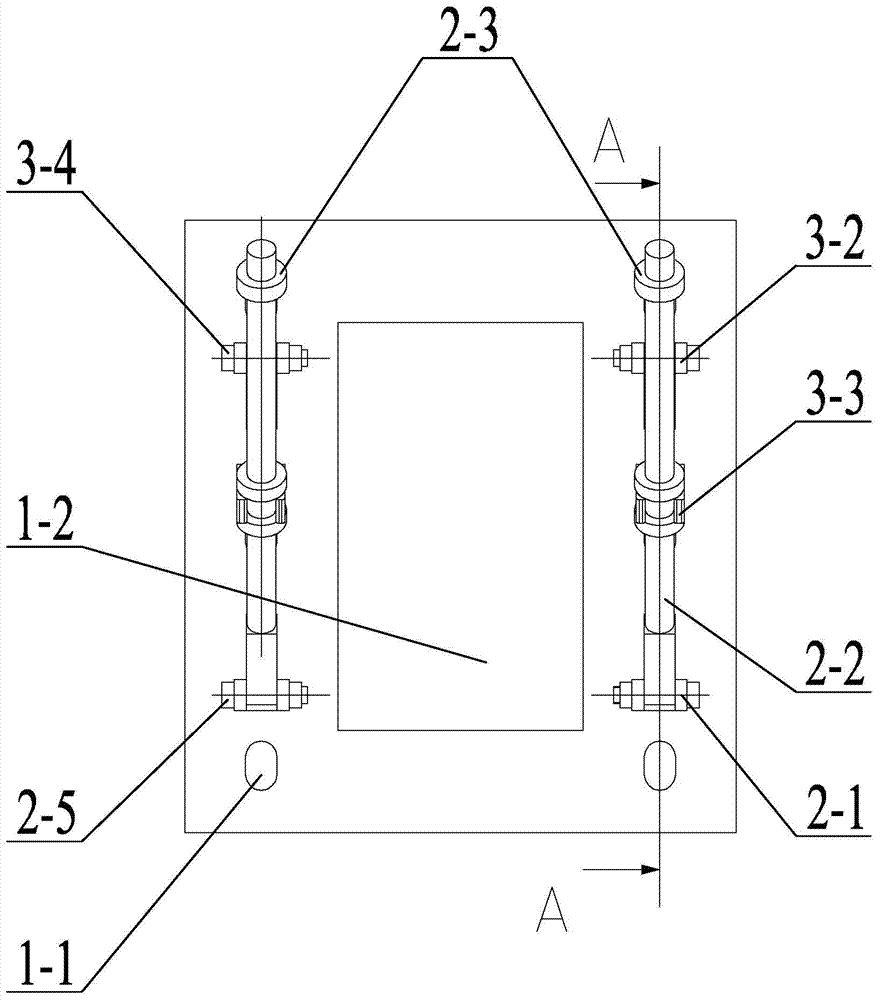

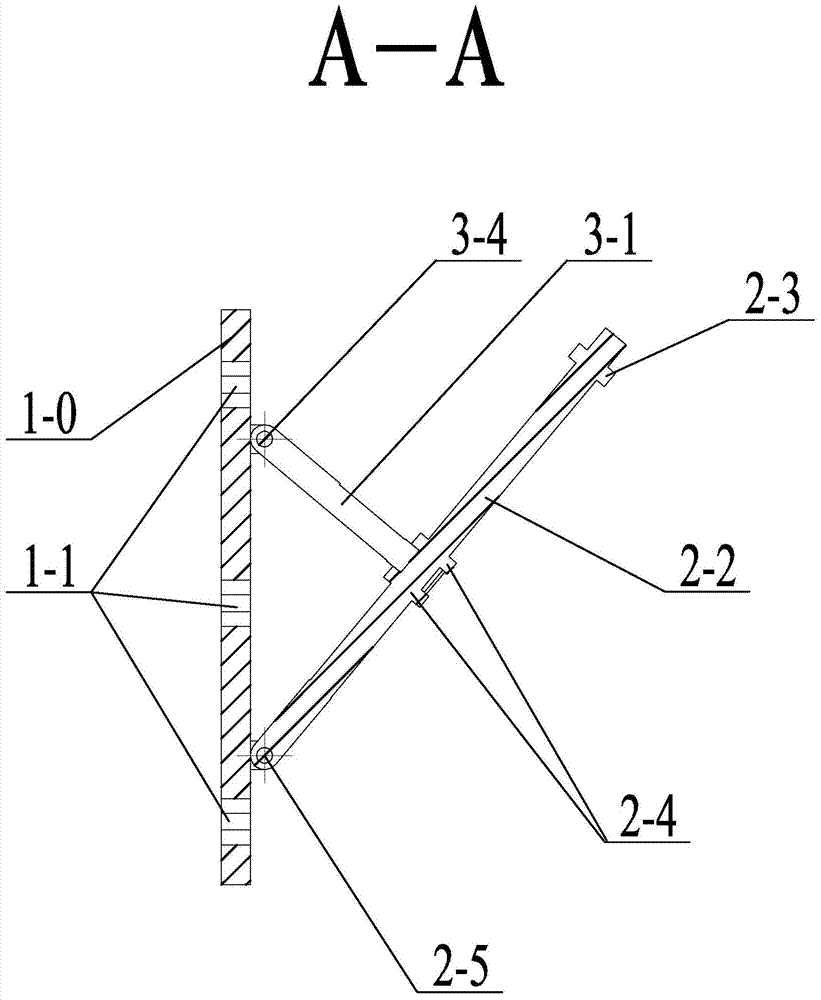

[0014] Specific implementation mode one: combine Figure 1 to Figure 6 Explain that the support frame for processing the oblique nozzle on the back of the high-pressure outer cylinder of the steam turbine with the horizontal rotary disk of the boring machine in this embodiment includes a base 1-0 and two support rod groups,

[0015] Each support rod group includes a high-pressure outer cylinder relying rod and a support rod,

[0016] The base 1-0 is a rectangular plate, and several through holes 1-1 are processed on the base 1-0.

[0017] The high-pressure outer cylinder relies on a rod to include a connecting ear assembly 2-1, a rod 2-2, a boss 2-3 and two stoppers 2-4, and the connecting ear assembly 2-1 is in contact with the upper surface of the base 1-0. Fixed connection, and one end of the connecting ear assembly 2-1 and the rod 2-2 is rotationally connected through the pin 2-5, the boss 2-3 is fixedly connected to the other end of the rod 2-2, and two stoppers 2-4 is ...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 1 to Figure 6 Note that the connecting ear assembly 1 2-1 of this embodiment includes two connecting ears 1, the two connecting ears 1 are arranged side by side and fixedly connected with the base 1-0, and the connecting ear assembly 2 3-1 includes two connecting ears 2 , the two connecting ears are arranged side by side and fixedly connected with the base 1-0. The first connecting ear, the second connecting ear and the threaded connector are easy to purchase and install, and have strong versatility and quick replacement. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figures 1 to 5 Explain that the rod one 2-2, the stopper 2-4 and the boss 2-3 of the present embodiment are all cylinders, and the stopper 2-4 and the boss 2-3 are fixed coaxially with the rod one 2-2 respectively. catch. The processing technology is simple, convenient for turning, and meets the requirements of manufacture and use. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com