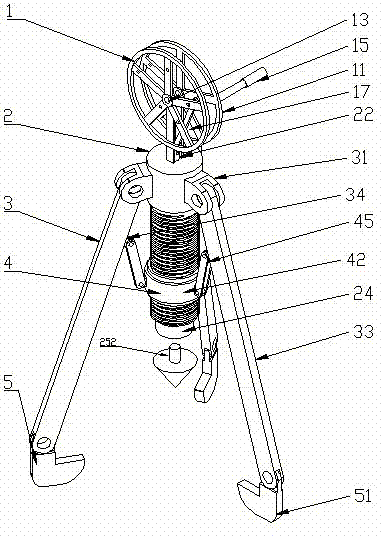

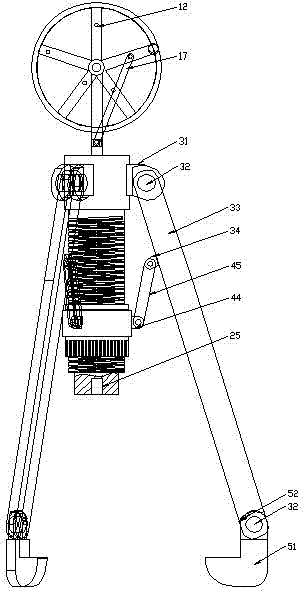

Dual-purpose three-claw puller

A three-jaw puller and dual-purpose technology, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of inaccurate fixing, helplessness in removing the circlip, and adjustment of the length of the lever handle, etc., so as to improve the effect of force application and have a wide range of applications , the effect of increasing the force surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

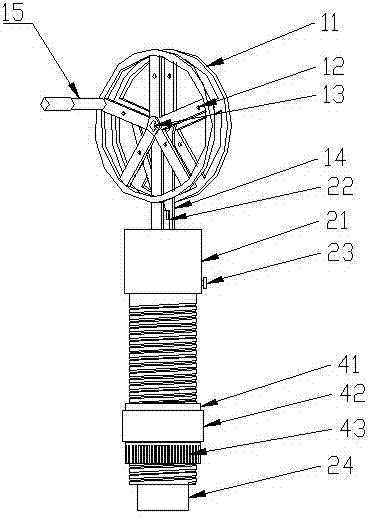

[0031] The specific implementation method: when adopting three-legged thimble 251 ( Image 6 ), adjust the opening and closing angle of the tripod on the three-legged thimble 251 according to clutches of different sizes, so that the three pressure rods can fit the pressure plate of the clutch, and then shake the rocking handle 15 to drive the pressure rod 22 to move. To achieve the purpose of dismantling the clutch; when the conical thimble 252 is used, the conical thimble 252 is directly pressed against the shaft end of the part, and then the rocker 15 is shaken, and the rocker 17 will drive the pressure rod 22 to pressurize the hydraulic cylinder and push The conical thimble 252 moves so that the parts can be slowly removed. If you want to adjust the speed and stroke of the push rod 22, the rocking rod 17 can be fixed on the positioning holes 12 at different positions by the pin shaft 16.

[0032] The claw device 3 is made up of a large hinged joint 31, a pin shaft 32, a cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com