Pneumatic tire

A technology for pneumatic tires and undertreads, applied to the reinforcement layer of pneumatic tires, special tires, tire parts, etc., which can solve the problems of low durability and achieve excellent durability and good handling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

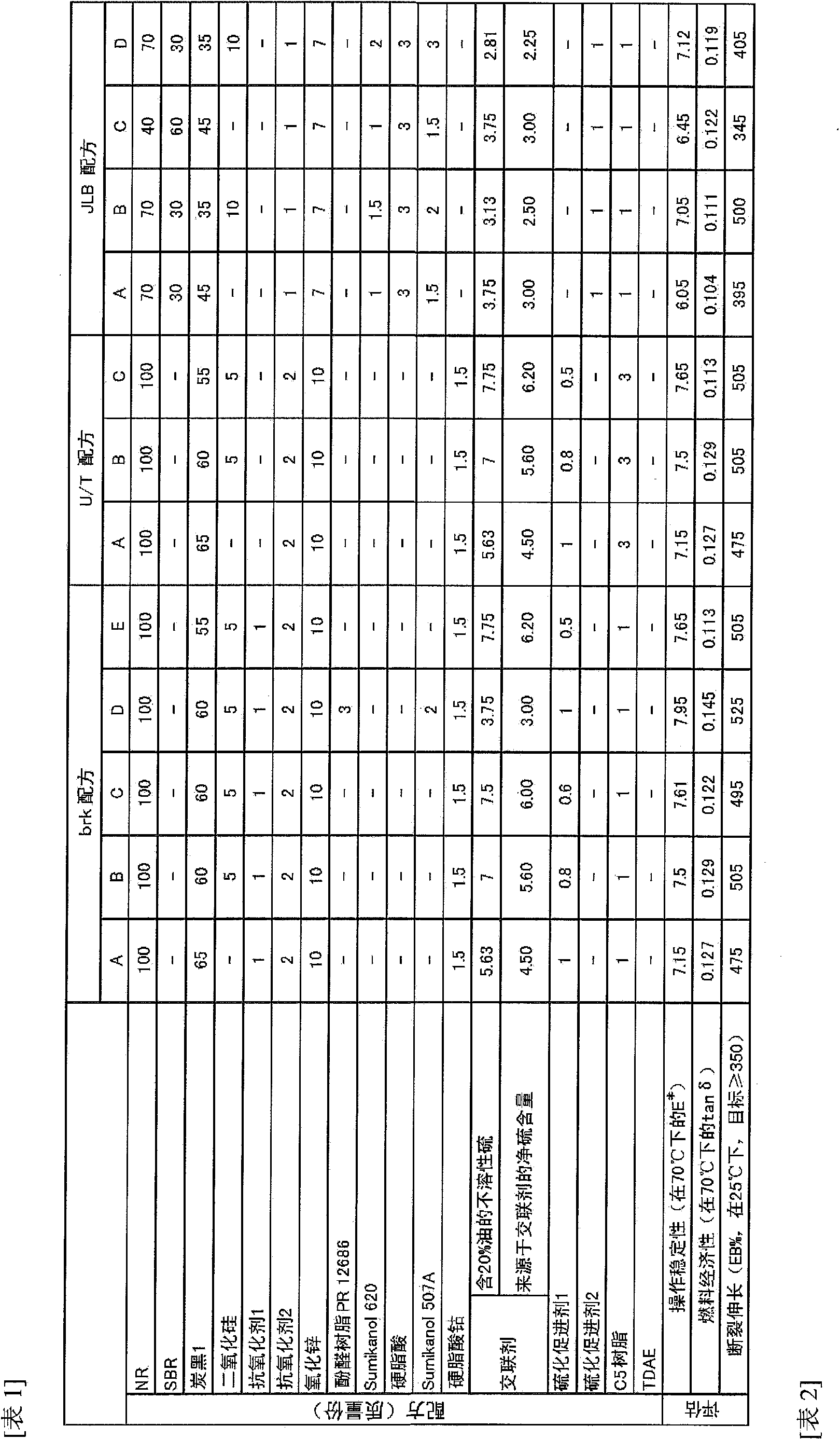

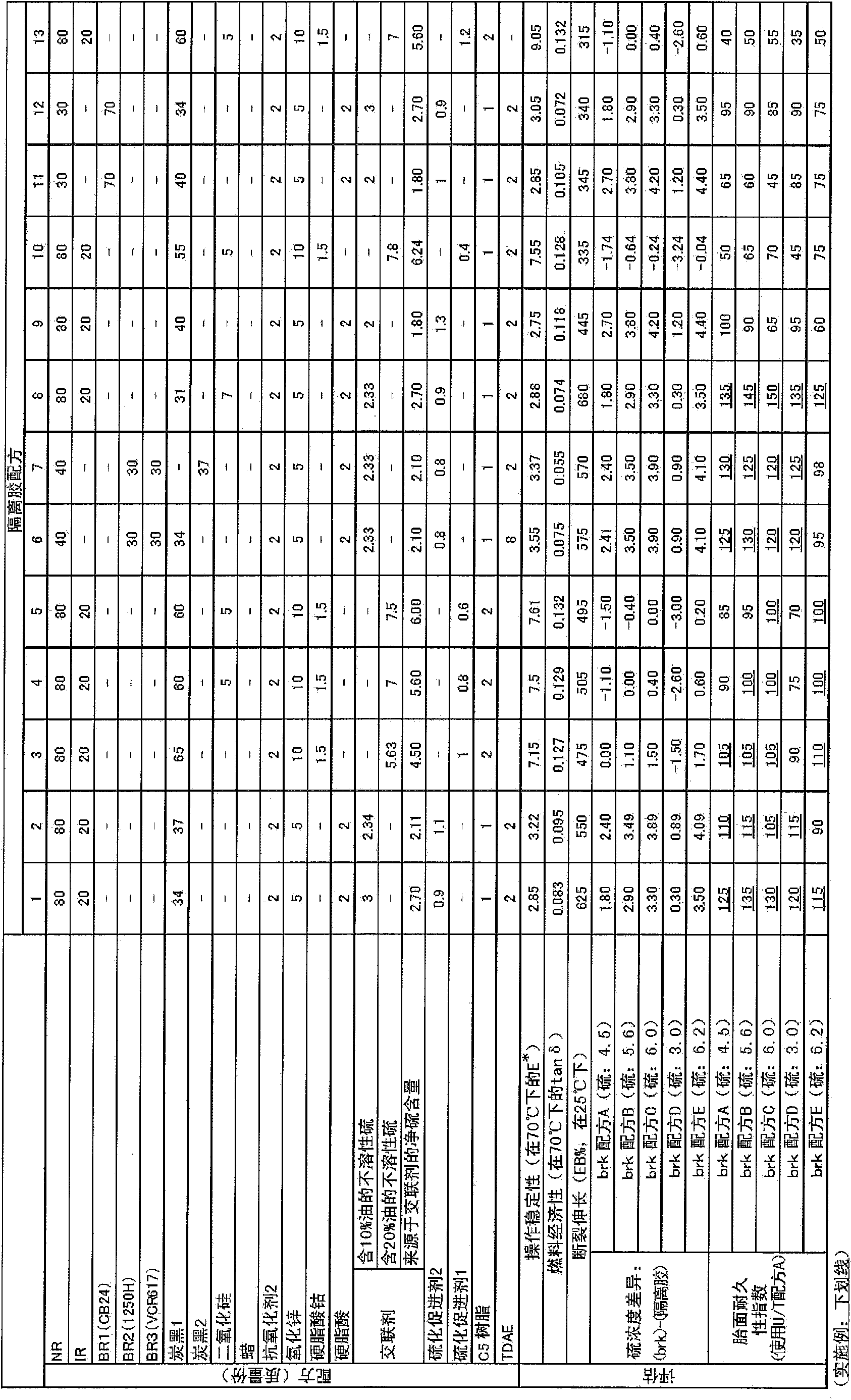

[0117] The following is a list of chemicals used in the Examples and Comparative Examples.

[0118] :TSR20

[0119] : IR2200

[0120] : CB24 (high cis BR synthesized with Nd catalyst), manufactured by LANXESS

[0121] : Nipol BR1250H (tin-modified BR polymerized with a lithium initiator, vinyl bonded amount: 10-13% by mass, Mw / Mn: 1.5, tin atom content: 250ppm), manufactured by ZEON Corporation

[0122] : VCR617, manufactured by Ube Industries, Ltd.

[0123] : SBR1502, manufactured by JSR Corporation

[0124] : Diablack N326 (N 2 SA: 84m 2 / g), manufactured by Mitsubishi Chemical Corporation

[0125] : Diablack N550 (N 2 SA: 41m 2 / g), manufactured by Mitsubishi Chemical Corporation

[0126] : ULTRASIL VN3 (N 2 SA: 175m 2 / g), manufactured by Evonik Degussa

[0127] : Ozoace0355, manufactured by Nippon Seika Co., Ltd.

[0128] : Antigene6C (N-(1,3-dimethylbutyl)N'-phenyl-p-phenylenediamine), manufactured by Sumitomo Chemical Co., Lt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com