Carbon fiber cable connector for cable-stayed bridge and installation method thereof

A carbon fiber and connector technology, which is applied in the field of carbon fiber cable connectors for cable-stayed bridges and their installation, can solve the problems of reduced durability of prestressed structures, stress corrosion, etc., and achieves reasonable structural design, large tensile-to-weight ratio, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

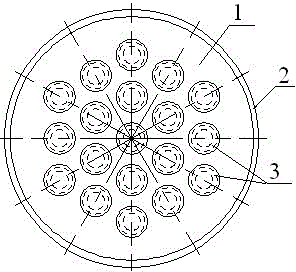

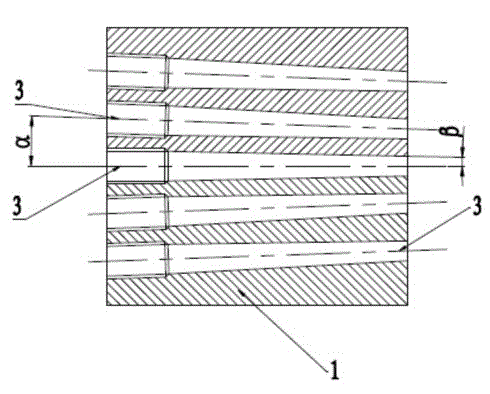

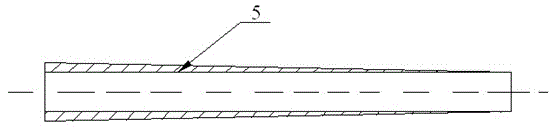

[0032] Such as Figure 1 to Figure 5 As shown, a carbon fiber cable connector for a cable-stayed bridge includes: a connector steel body (1), a harness sheath (2) coated on the outer periphery of the connector steel body (1), and the connector A plurality of frustoconical holes (3) of equal size are arranged inside the steel body (1), and wedge-shaped wire clamps (5) are installed in the frustoconical holes (3) through hollow bolts (4).

[0033] The above-mentioned carbon fiber cable connector for the cable-stayed bridge, the truncated conical hole (3) inside the connector steel body (1), except the truncated conical hole (3) coaxial with the connector steel body (1) ), the axes of the remaining frustoconical holes (3) form an angle of 5 to 10 degrees with the central axis of the connector steel body (1), and the distance between each adjacent frustoconical holes (3) is equal .

[0034] In the above-mentioned carbon fiber cable connector for a cable-stayed bridge, the includ...

Embodiment 2

[0036] 1) Grind and clean both ends of the carbon fiber cable, and the length of the grinding is 1.5 times the length of the steel body of the connector;

[0037] 2) Pass one end of the carbon fiber cable (6) through the frusto-conical hole (3) inside the connector steel body (1), then pass the carbon fiber cable (6) through the center hole of the wedge clamp (5), and Install the wedge-shaped clamp (5) in the truncated-conical hole (3), and finally tighten the hollow bolt (4) on the steel body of the connector, thereby fastening the wedge-shaped clamp (5) in the truncated-conical hole (3). inside the hole (3);

[0038] 3) Pass the other end of the carbon fiber cable (6) through the truncated conical hole (3) inside the connector steel body (1), the wedge-shaped clamp (5), the hollow bolt (4), and make the truncated cone shaped hole (3), the wedge-shaped clamp (5) and the hollow bolt (4) are not tightened; then install the pre-tightening force assembly (7) at the end of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com