Rammer release device of dynamic compactor

A technology of dynamic tamping machine and hammer removal, which is applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of high cost, complicated operation, and high free height of the hammer removal device, so as to improve work efficiency and reduce free height , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

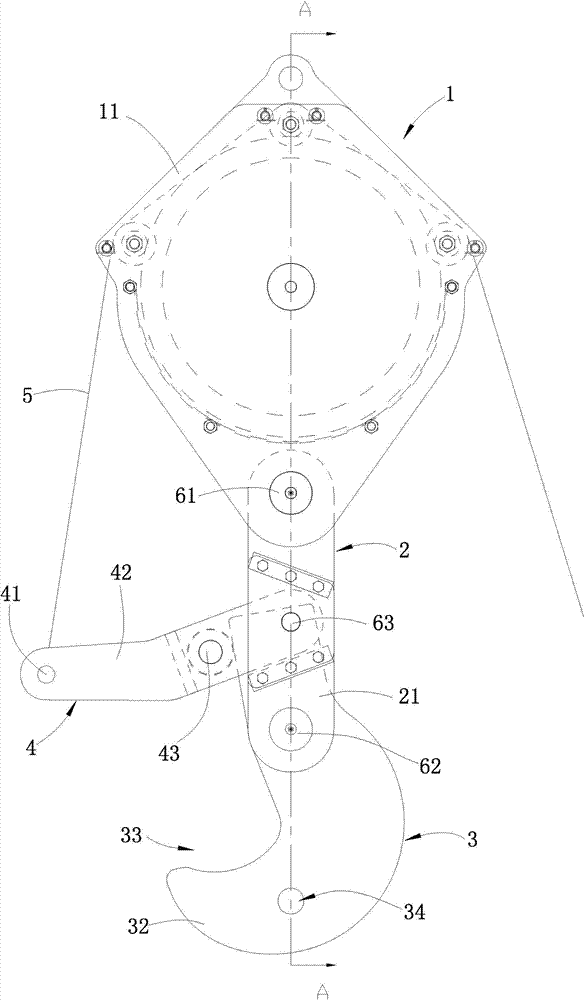

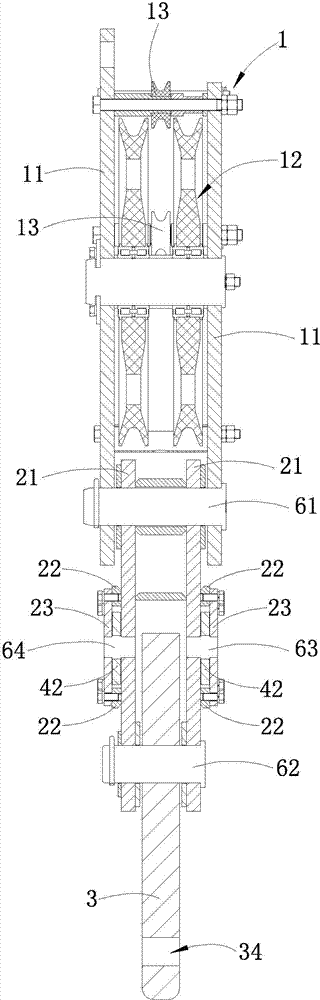

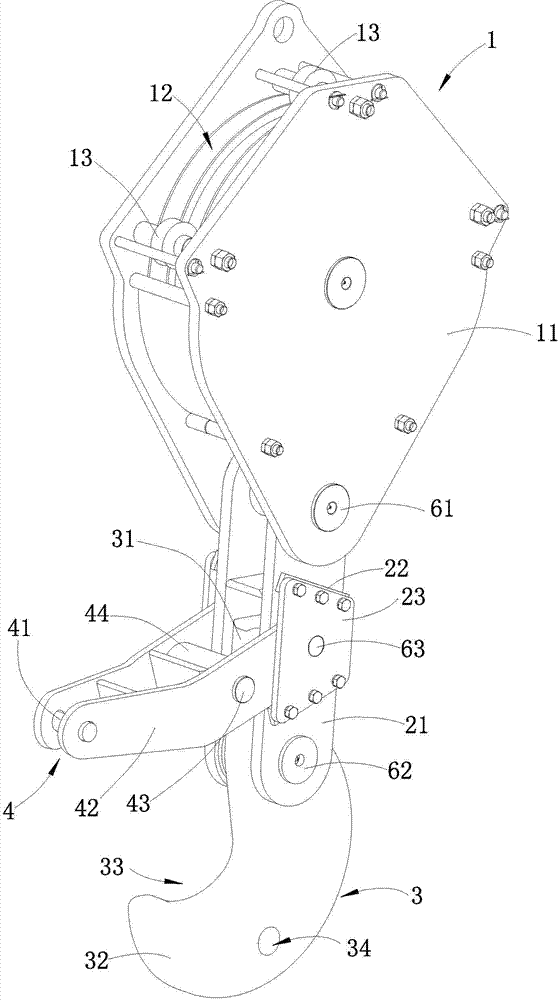

[0022] Such as Figures 1 to 3 shown (for ease of understanding, figure 2 and image 3 Omit the hammer wire rope 5)

[0023] The hammer removal device includes a lifting frame 1, a hammer removal assembly, a connecting frame 2 and a hook 3.

[0024] Lifting frame 1 comprises two lifting plates 11 placed in parallel, and lifting pulley block 12 is housed between two lifting plates 11, and three guide wheels 13 are also installed on lifting frame 1, and three guiding wheels 13 are installed on the sides of lifting frame 1 respectively. Upper left side, lifting frame 1 upper end and lifting frame 1 upper right side.

[0025] The lower end of the lifting frame 1 is hinged with a connecting frame 2 . The connecting frame 2 includes two connecting plates 21 placed in parallel.

[0026] The suspension hook 3 is hinged between the lower ends of the two connecting plates 21 through the second pin shaft 62. The suspension hook 3 includes an upper hook handle section 31 and a hook h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com