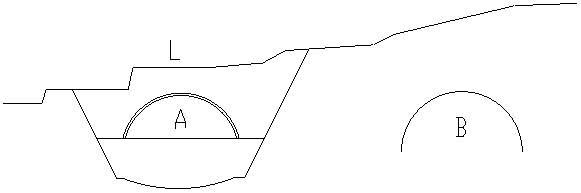

Semi-covering semi-darkened construction method for separated tunnels downwards penetrating through high and steep V-shaped gully eccentric compression section

A construction method and separate technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of large buried depth and small buried depth of tunnels, and achieve small excavation volume, reduced impact, and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, rather than for limiting the protection scope of the present invention.

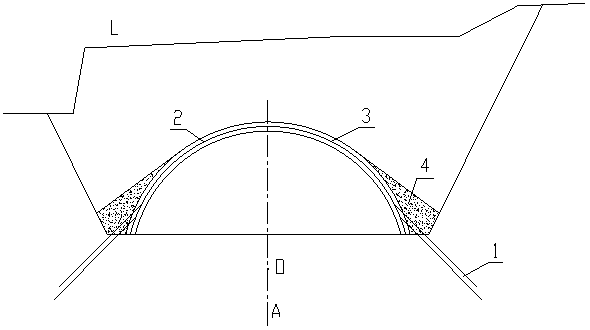

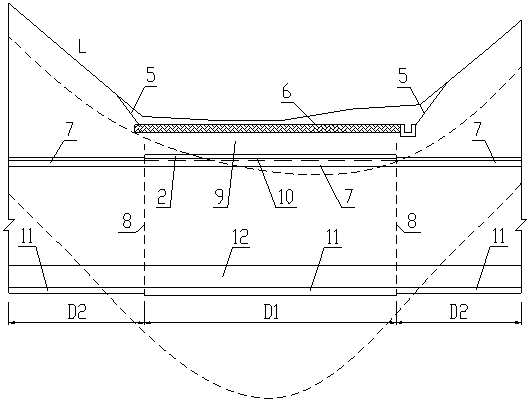

[0049] Taking a two-way four-lane split tunnel of a highway passing through the biased section of a high and steep V-shaped gully as an example: the starting and ending mileage of the over-gully section of the tunnel is K120+721~K120+739, and the length is 18m, all of which are V-level enclosures. rock. The distance from the vault to the surface of the gully section in the left hole of the tunnel is 3.6m, and the distance from the vault to the surface of the gully section in the right hole is 6.5m. The geological conditions of the stratum in this area are as follows: 0~1.4m below the surface is brown-yellow sloping gravel soil with relatively wet humidity, the main p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com