Multifunctional rotor test bench

A kind of experimental platform and multi-functional technology, which is applied in the direction of measuring devices, instruments, mechanical parts testing, etc., can solve the problem of compound fault blank, etc., and achieve the effect of wide application range, multiple functions, and intuitive experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

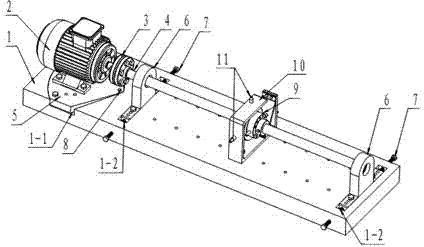

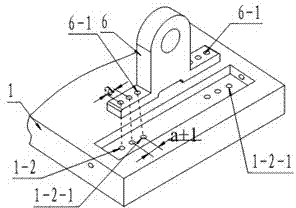

[0023] see figure 1 , the present invention includes a base 1, a motor 2, a shaft coupling 3, a rotor 4, a shaft misalignment fault simulation mechanism and a dynamic and static rubbing simulation mechanism, and the motor output shaft and the rotor are connected by a coupling. Utilize the present invention can carry out following experiment:

[0024] 1. Simulate different degrees of shafting misalignment faults within a certain range;

[0025] 2. Simulate different degrees of dynamic and static rubbing (including full-circle rubbing and partial rubbing) faults;

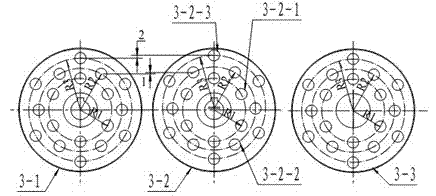

[0026] 3. Simulate different degrees of rotor mass unbalance faults;

[0027] 4. Simulate any two or even three composite faults of different degrees of misalignment faults, dynamic and static rubbing faults, and mass unbalance faults.

[0028] The first experiment of the present invention is completed by a shafting misalignment fault simulation mechanism, which includes a motor turntable, two bearing seats support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com