Vertical-type foundry sand five-intensity testing device and foundry sand intensity acquiring method based on device

A testing device and casting mold technology, which is applied in the field of casting sand, can solve the problems of pollution tester and sand samples, easy leakage of hydraulic oil, and inaccurate testing results of sand strength, so as to improve test accuracy, overcome static friction and Manual loading is unstable and avoids the effect of easy pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

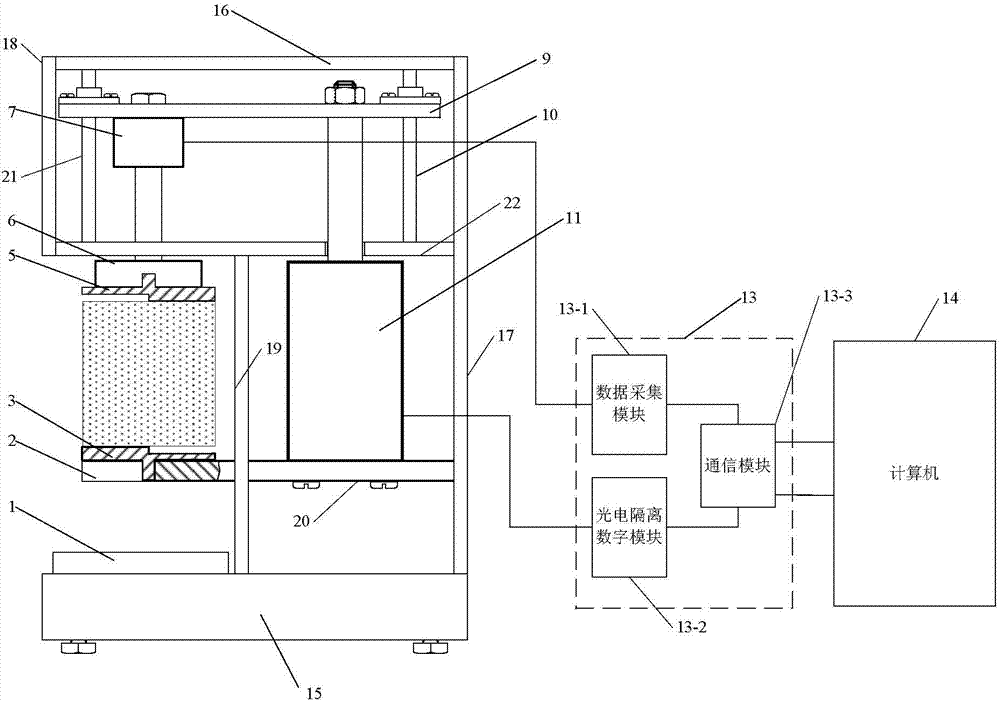

[0015] Specific implementation mode 1. Combination figure 1 Describe the specific embodiment, the foundry sand five-intensity vertical test device described in the specific embodiment includes a base 15, a lower pressure head seat 2, a lower pressure head 3, an upper pressure head seat 6, an upper pressure head 5, and a tension sensor 7. Loading force transmission plate 9, first guide rod 21, second guide rod 10, linear motor 11, top plate 16, baffle plate 22, left side plate 18, right side plate 17, vertical plate 19, fixed plate 20, all Said left side plate 18 and right side plate 17 are respectively fixed on the left and right sides of top plate 16, baffle plate 22 is fixed between left side plate 18 and right side plate 17 and is positioned at the below of top plate 16, and baffle plate 22 and top plate 16 Parallel to each other, one end of the first guide rod 21 and one end of the second guide rod 10 are vertically and symmetrically fixed on the lower surface of the top p...

specific Embodiment approach 2

[0016] Embodiment 2. The difference between this embodiment and the five-strength vertical testing device for foundry sand described in Embodiment 1 is that the tensile pressure sensor 7 has a range of 0-3000N and an accuracy of 0.1%.

specific Embodiment approach 3

[0017] Embodiment 3. The difference between this embodiment and the five-strength vertical testing device for foundry sand described in Embodiment 1 is that the thrust range of the linear motor 11 is 0-3000N, and the linear motion speed is 1mm / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com